Thermal Shock Resistant Materials: The Case for Glass-Ceramics

SCHOTT AG

Many industrial and commercial applications entail conditions where sudden changes in temperature take place, either during heating or cooling. Such abrupt temperature changes are called thermal shocks, and these shocks can significantly affect the materials used. For that reason, thermal shock resistant materials are needed in order to withstand such vast temperature variations. One material that stands out in its class in terms of thermal shock resistance is glass-ceramics. So, what is thermal shock resistance exactly? How does it affect material selection in different applications? And what makes glass-ceramics a noteworthy thermal shock resistant material?

What is thermal shock resistance?

Thermal shocks in materials are a result of temperature gradients and rapid temperature changes. They occur in materials that have particular defects or are used inadequately. Such gradients may bring about random expansions at different locations inside the material. Consequently, stress and strain zones begin to develop during operation, producing cracks throughout the material. Such stresses are said to be higher than normal-loading-cycle stresses or even higher than the material’s ultimate tensile strength. These can lower the material’s ductility and fatigue life. Such a condition makes the material more prone to fracture, which could be potentially dangerous.

Therefore, engineers focus on selecting the right materials that can resist prompt and abrupt variations in temperature. Such materials are called thermal shock resistant materials. Generally, materials with a low coefficient of thermal expansion (CTE) and high thermal conductivity are considered the best resistant materials to thermal shocks. On the other side of the spectrum, materials with a high CTE and a low thermal conductivity are the most susceptible to thermal shocks.

Thermal shock resistance can be improved by reducing thermal gradients or enhancing the material’s robustness – or in fact, selecting a highly robust material. This is done by increasing a critical parameter called the thermal shock parameter. This indicates the material’s thermal shock resistance capacity and is evidently proportional to the material’s thermal conductivity and ultimate tensile strength. It is also inversely proportional to the material’s CTE and elastic modulus.

Thermal shock resistant materials

The thermal shock behaviour of materials is a crucial parameter in determining whether the material is appropriate for a particular application, especially those under high temperature. The safest and most practical way to ensure that there is no risk of mechanical failure due to thermal shocks would be to carefully select the material that can withstand significant thermal shocks and remain fully functional.

Common materials that are able to withstand wide temperature changes include silicon nitride (Si3N4) and ceramic matrix composites, such as carbon-fibre-reinforced zirconium carbide (C/C-ZrC) and carbon-fibre-reinforced silicon carbide (C/C-SiC). These materials are rightly used in aeronautical and aerospace applications.

However, in another type of applications that requires more than just high thermal properties, one interesting material distinctly emerges with significant values defining a high resistance to thermal shocks. This material is glass-ceramics.

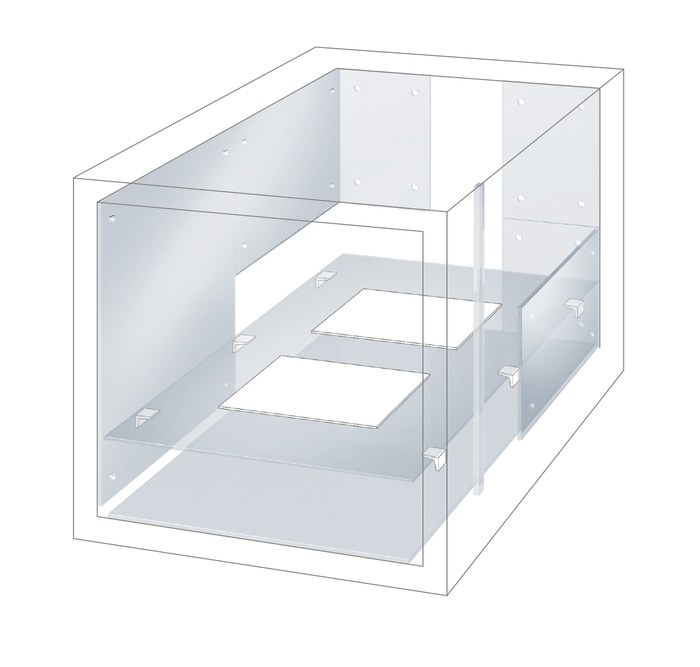

Courtesy of SCHOTT NEXTREMA®.

Glass-ceramics is a unique material that sits between glass and polycrystalline ceramics. It is produced by combining glass phases with crystalline phases that emanate from controlled nucleation and crystallisation of glass. Interestingly enough, this material practically shows almost no evidence of expansion over a broad range of temperatures.

It benefits from a very low CTE, making it highly resistant to thermal shocks. In addition to that, its exquisite optical features and high mechanical and chemical properties allow it to be used in various applications where other materials may fail to meet the requirements. For example, the NEXTREMA® materials by SCHOTT not only exhibit broad optical properties but also have a thermal shock resistance to temperatures reaching up to 600 – 820 ºC (depending on the NEXTREMA® type). This guarantees a reliable performance, especially under high-temperature conditions, while having the sleek look and finish of glass. NEXTREMA® materials can be used in various applications such as industrial furnaces, infrared heaters, domestic electrical appliances, heating devices, refractories, and additive manufacturing.

As a matter of comparison, silicon carbide (SiC) and sintered silicon carbide (SSiC) have thermal shock parameter values lying around 200 ºC. Silicon nitride (Si3N4) can resist up to 560 – 760 ºC. Zirconium oxide’s (ZrO) thermal shock parameter ranges between 280 – 400 ºC. This shows how significant glass-ceramics is in terms of its thermal properties. In other words, if you are in search of a material that can secure a long life with reliable performance under high temperatures and sudden temperature changes, glass-ceramics is definitely worth considering.

Courtesy of SCHOTT NEXTREMA®.

It’s easy to find glass-ceramics

Such a material is absolutely transformative in terms of what it provides us in functionality, reliability, and modern aesthetics. Material providers continue to invest in glass-ceramics and develop the underlying technology to make sure that a material of this calibre can meet our industrial, technological, and commercial demands.

SCHOTT AG, producer of NEXTREMA® materials, is a leader in producing specialty glass and glass-ceramics worldwide. It has been providing services and innovation in glass technology for over 130 years. It has enabled innovation in a variety of industries, such as home appliance, electronics, optics, pharma, aviation, and automotive industries.

Visit the SCHOTT AG supplier page for more information on their materials listed on Matmatch and to get in direct contact with them.

Article by SCHOTT AG - NEXTREMA®

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment. This is also what the SCHOTT NEXTREMA® brand stands for. With high-performance glass-ceramic, SCHOTT offers a portfolio of materials that opens completely new fields of application for engineers and designers with its exceptional technical properties. As a real multi-talent, NEXTREMA® demonstrates what makes glass-ceramic a ground-breaking and unique solution, particularly in high temperature environments.