Why Glass-Ceramics are an Ideal Material for High-Temperature Applications

SCHOTT AG

For millennia, glass has been used as material for countless purposes, from making weapons and decorations to applications in architecture, science, optics, technology, and general-purpose everyday uses. In today’s world, glass still remains one of the most commonly used materials. However, when it comes to high-temperature applications, glass begins to reach its limits as thermal shocks and thermal expansion could lead to its break and failure. An alternative material that fits perfectly for such applications is glass-ceramics. It often has the same look and feel as glass but with a set of unique properties that allow it to excel under extreme conditions. One company that has been at the centre of innovation and supply of glass and glass-ceramics is SCHOTT AG. So, why are glass-ceramics the go-to material in high-temperature applications, and how are companies like SCHOTT AG advancing the technology around it?

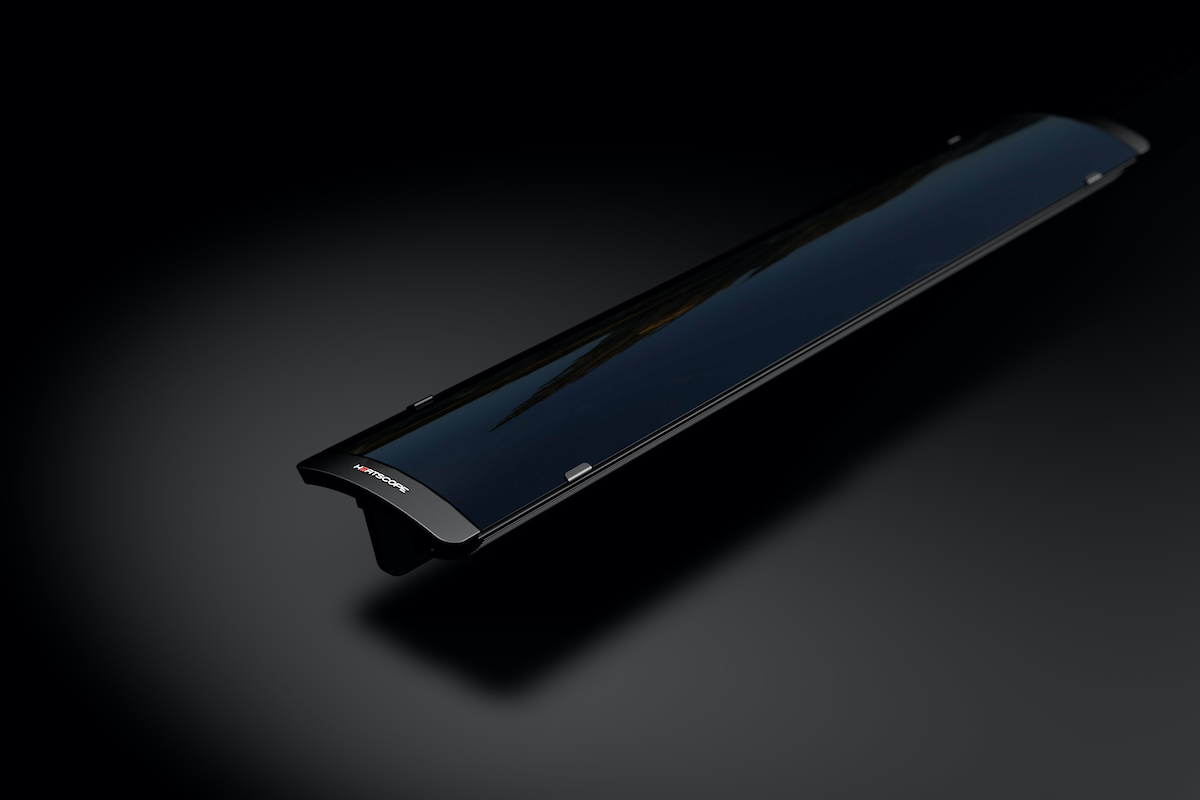

Figure 1. NEXTREMA® transparent (724-3). Courtesy of SCHOTT NEXTREMA®.

Due to glass’s intrinsic physical and chemical properties that bring about a variety of different formulations, the material is a popular choice in a wide range of applications. Soda-lime glass, borosilicate glass, and aluminosilicate glass are some of the most commonly used ones. Favourable properties of these different glass types include chemical inertness, high heat resistance, transparency, hardness, and resistance to corrosive environments.

Nonetheless, some applications take place under extreme conditions, and those require materials with unique properties that can withstand these conditions. Such applications are usually headlined by high-vacuum and high-temperature applications. In space, for instance, telescopes might detect temperature fluctuations that could affect the quality of images. For that, a material with an extremely low thermal expansion coefficient is required, so that no change in shape occurs upon heating and cooling. Such kind of material has been produced for over half a century, and it goes by the name of glass-ceramics. Although glass-ceramics occur naturally as in the volcanic glass obsidian, they were first synthetically produced in 1953.

What are glass-ceramics?

Whereas spontaneous crystallisation of glass during cooling is disadvantageous, glass-ceramics are actually produced via controlled crystallisation. They comprise polycrystalline regions that grow within a matrix of residual glass. This composition allows them to combine the top properties of both glass and ceramics in one material. For example, transparency and low coefficient of thermal expansion are essential properties for infrared heaters, and they are found in glass and ceramics, respectively.

In addition to that, glass-ceramics have enhanced strength and chemical resistance compared to glass, and they exhibit high dimensional stability, extremely low porosity, resistance to thermal shocks, and mechanical impacts. All these features are key for high-temperature applications.

Glass-ceramics can be mass-produced via typical glass-forming processes. The crucial step is adding a nucleating agent to the raw materials. This agent’s impact lies in enabling crystal nuclei to form when the melted materials are cooled. The nuclei, then, grow with increasing temperature to constitute a crystal structure. This gives rise to a material that has the same look and feel as glass yet is significantly more durable and more resistant to temperature changes.

Furthermore, the properties of glass-ceramics are modifiable and can be boosted by adjusting certain aspects in the manufacturing process, such as the chemical mixture and heating time. For their high-temperature applications, engineers and product designers can highly benefit from such a material.

One example is SCHOTT’s NEXTREMA® material platform, which is designed for extreme conditions. NEXTREMA® materials are resistant to high temperatures reaching up to 950ºC (1742ºF). They are also highly durable with near-zero thermal expansion, even in demanding environments. They have a high thermal shock resistance for temperatures up to 820ºC (1508ºF) with excellent intrinsic mechanical resistance. As glass-ceramics, NEXTREMA® is chemically inert and can perform reliably even under extreme conditions.

Figure 2. Infrared radiant heater with high-quality SCHOTT NEXTREMA® glass-ceramic cover. Courtesy of © heatscope.com.

Are glass-ceramics the right material for high-temperature applications?

Yes, they are. Glass-ceramics can provide solutions to many problems that arise from demanding conditions and challenging environments in high-temperature applications.

Commercially viable glass-ceramics range from infrared heater covers in modern homes all the way to carrier plates in the AMOLED production. For an application that requires properties like low thermal expansion coefficient, high strength, and wear resistance, especially in high-temperature situations such as atmospheric re-entry, aerospace engineers can find all these properties put together only in glass-ceramic materials.

Similarly, in applications closer to us, such as infrared heaters in modern houses, high-temperature furnaces, barbeque grills, and household heating appliances, glass-ceramics stand out with their sleek, stylish look, the versatile material options, and their ability to resist different influences.

Again, NEXTREMA® fits perfectly well with such an application, and it does that with style. Its unique properties allow designers to come up with stylish designs for their products while providing high thermal, chemical, mechanical, and optical features.

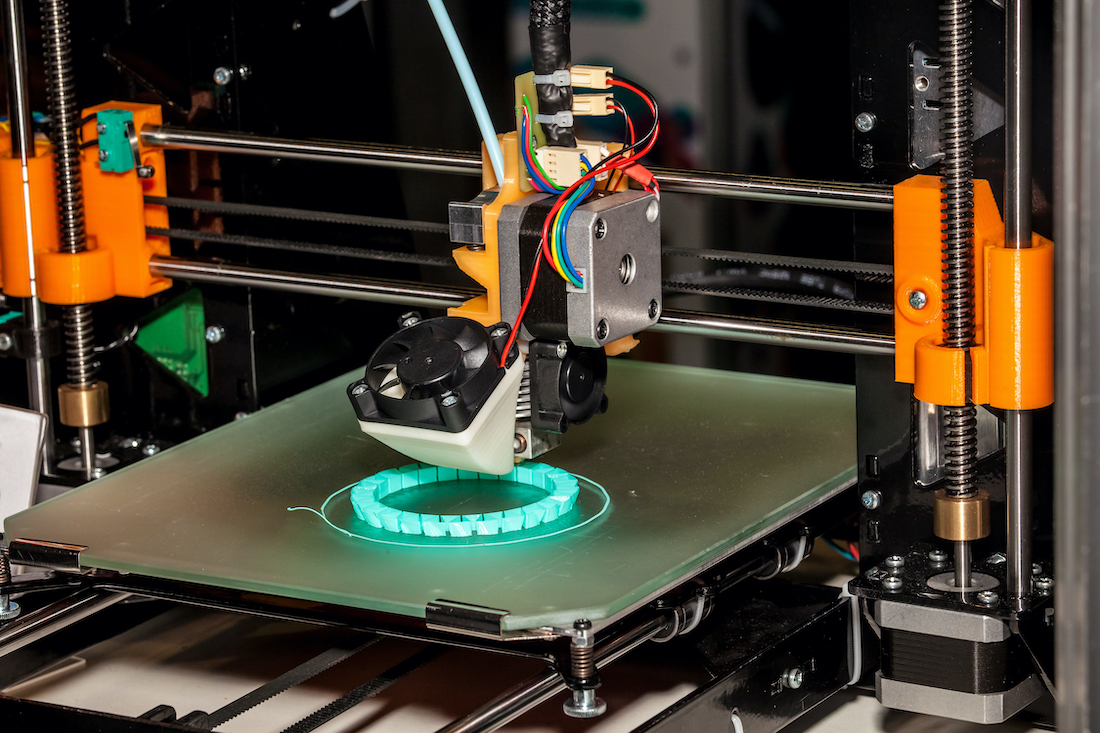

Another example use of NEXTREMA® glass-ceramic is in heat beds in 3D printers. Additive manufacturing has been a revolutionary technology, but it can only be as good as the materials used in it are. That’s why heat beds are preferably made of glass-ceramics, benefiting from their low porosity, thermal shock resistance, and high service temperature.

Figure 3. A glass-ceramic heat bed holding a 3D-printed part during fabrication.

Innovation in glass-ceramics

Glass-ceramics is a game-changing material, and it has been continuously developed and improved with the evolution of our daily lives and technological demands. Suppliers and material producers are highly invested in advancing the technology around glass-ceramics.

SCHOTT AG, a leading international technology group in specialty glass and glass-ceramics, has been providing services and innovation in glass technology for over 130 years. It has enabled innovation in a variety of industries, such as home appliance, electronics, optics, pharma, aviation, and automotive industries.

Visit the SCHOTT AG supplier page for more information on their materials listed on Matmatch and to get in direct contact with them.

Artikel von <a href=/suppliers/scho-schott-ag-nextrema-> SCHOTT AG - NEXTREMA® </a>SCHOTT AG - NEXTREMA®

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment. This is also what the SCHOTT NEXTREMA® brand stands for. With high-performance glass-ceramic, SCHOTT offers a portfolio of materials that opens completely new fields of application for engineers and designers with its exceptional technical properties. As a real multi-talent, NEXTREMA® demonstrates what makes glass-ceramic a ground-breaking and unique solution, particularly in high temperature environments.