Vickers Hardness Test: What it is and how it’s measured

How often have you wondered if a material you need for your project is hard enough for its intended purpose? Hardness is a critical property for many applications. Fortunately, there is a relatively easy method to measure the hardness of materials, called the Vickers Hardness test.

According to the Metals Handbook, hardness is defined as the “resistance to plastic deformation”. Since different materials behave in different ways, there are three kinds of hardness that are typically measured. Depending on the material, they are:

- indentation hardness

- scratch hardness

- rebound hardness

The Vickers Hardness test measures the indentation hardness for small parts or thin sections of metals, ceramics, and composites – almost any type of material in fact.

How is the Vickers Hardness test carried out?

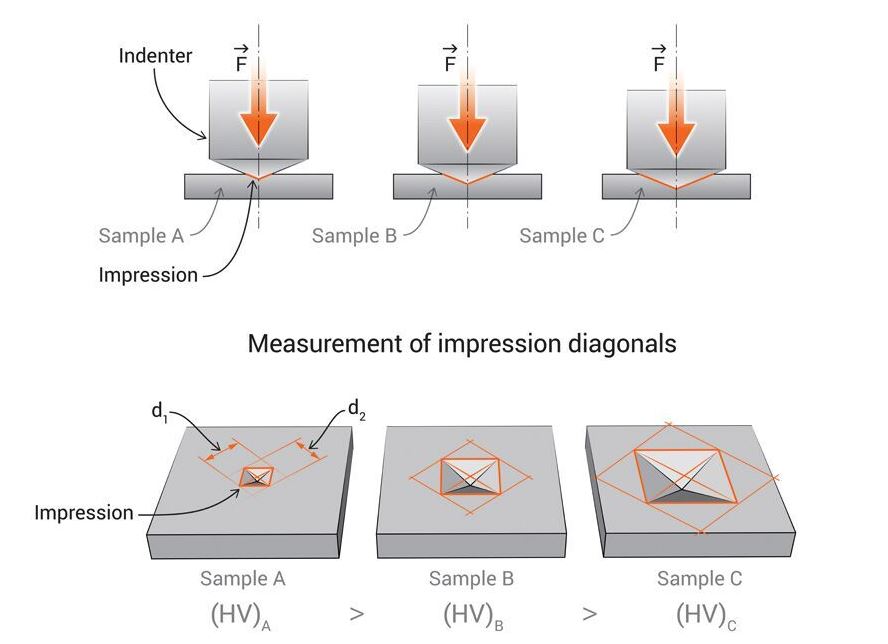

This test consists of applying a force (also called a “load”) on the test material using a diamond indenter, to obtain an indentation. The depth of indentation on the material gives the value of hardness for the specimen. In general, the smaller the indentation, the harder the object is. Hardness tests can be classified into micro-indentation tests and macro-indentation tests, depending on the force that is applied to the test material. (Micro-indentation tests typically use loads of up to 200 gf, while macro-indentation tests use loads up to 1000 gf). The Vickers Hardness test and Knoop Hardness test are the most commonly used tests that can be used for both micro-indentation and macro-indentation.

Vickers Hardness Test indentation examples – 3 materials of different hardness. Image is © 2017 EngineeringClicks

Why use the Vickers Hardness test?

Initially designed as a substitute for the Brinell method, which had a large indenter and the possibility of damage to the test-piece, and also the Rockwell method which used multiple test forces; the Vickers Hardness test is easy to use and offers a number of advantages over other hardness tests, such as:

- the indenter used is small in size, which reduces the risk of possible damage to the test material

- the indenter can be used for any kind of material, irrespective of its hardness

- the resulting calculations are independent of the size of the indenter

- it has a very wide scale, compared to other hardness tests

- a single test force is applied

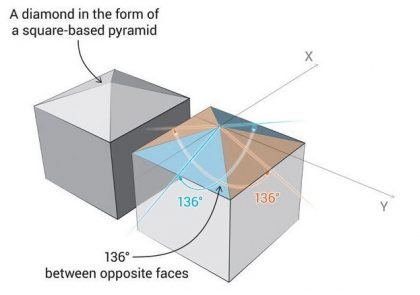

Close up of a diamond tipped indentor

How is the hardness measured?

The test is implemented by pressing the diamond indenter into the surface under testing. The indenter is pyramid-shaped, with a square base and an angle of 136 degrees between opposite faces. Typically, loads vary from 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

Vickers Hardness Test indentor geometry.

The length of both diagonals formed on the test surface is measured, and the average is used for calculating the hardness, given by the ratio F/A (where F is the force or load, in kgf; and A is the surface area of the indentation, in sq. mm.). The hardness value is expressed as Vickers Hardness (HV) or Diamond Pyramid Hardness (DPH) (usually a number, without units).

The measurements are made using built-in microscopes. Some more advanced testing scales use software to obtain faster and more accurate results.

Applications

The indentation produced by the Vickers test is relatively small, and therefore, it is extremely useful in testing the hardness of small parts or sections and very thin objects like foils for example.

Things to consider

To obtain accurate results from the test, it’s best to consider the following:

- choosing a sample that is small enough to fit on the scale

- making the surface of the test material smooth, in order to achieve a proper indentation and to minimize error in measurement. Additionally, this helps in holding the material perpendicular to the indenter

- making the indentations as large as possible to maximize the accuracy of measurement (the possibility of error is higher as indentation size decreases)

Limitations

Despite all its advantages, the Vickers Hardness test has its own limitations. Critics argue that at lower loads, there is a degree of bias that sets in. Some test materials are pre-coated, in which case the thickness of the coating affects the accuracy of measurement for micro-indentations. To overcome this, advancements in the field of nanotechnology have resulted in the development of nano-indentation methods.

Conclusion

The Vickers Hardness test is easy to use, and its benefits far outweigh any potential disadvantages. The versatility of its use – the fact that it can be used to measure the hardness of almost any type of material – still makes it very attractive and widely applicable.