Yield Strength of Plastics – Basic principles, the Tensile Test and Material Property Table

Why do some plastics break cleanly and others deform and elongate prior to breaking? This is a common question and an important phenomenon to understand. The yield strength of plastics holds the key.

Many plastics are used to replace metals. Here, it is important to understand the so-called strength-to-density ratio. Plastics are typically much less dense than metals, which help with mechanical efficiencies and the reduction in energy load, but one must understand the strength of the plastic.

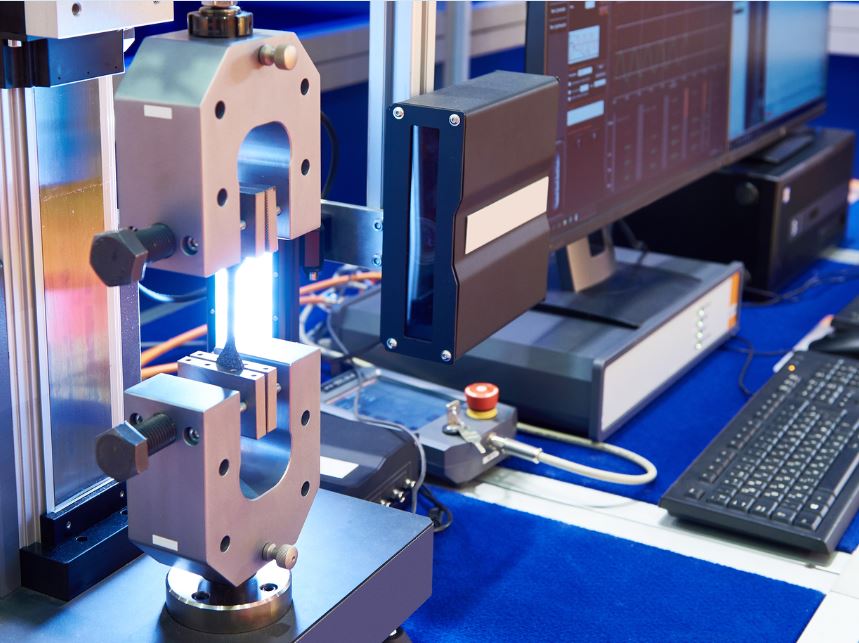

The most common way to measure the yield strength of plastics is with a tensile test. A tensile test is typically governed via standards, and the two most common in the plastics industry are ASTM D638 and ISO 527.

The tensile test

The test measures the force as a function of the strain being applied to the plastic sample. An example of the test setup is shown below.

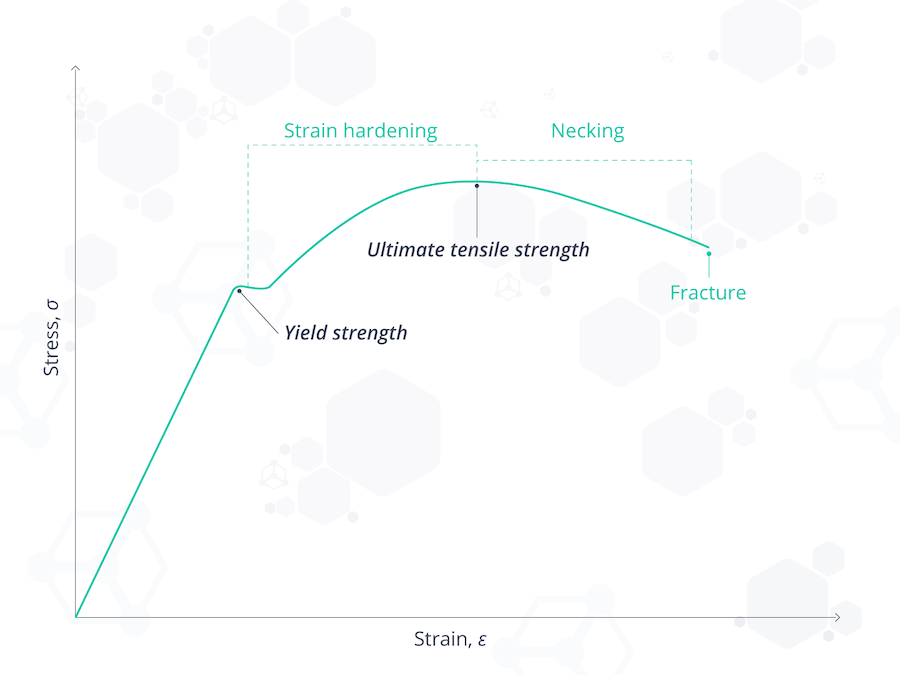

From this test, many important mechanical properties can be derived. A graph showing a common stress-strain curve for a plastic material is shown below.

Important terms to keep in mind

- Young’s Modulus – This is the slope of the linear portion of the curve. Another term for it is elastic modulus; it is a quantitative way to describe the linear elastic behavior of the material. Units are typically in Pascals (Pa) or pounds/inch (psi).

- Yield Strength – The yield strength of the plastic is where the material begins to deform in a plastic fashion. Prior to the yield strength, the material will act elastically, meaning that if the strain were halted at any point in the elastic portion, the material would return to its original length. Once the yield strength of the plastic is attained, the material will not return to its original length and will yield. Units are typically in Pascals (Pa) or pounds/inch (psi).

- Ultimate Strength – The ultimate strength is the maximum amount of stress that can be applied. Units are typically in Pascals (Pa) or pounds/inch (psi).

- Fracture – The point at which the material snaps.

- Strain hardening – This is the region where the material is experiencing some deformation but can receive additional stress without weakening.

- Necking – This is the region where the material has passed the ultimate strength, is not deforming significantly anymore, and is visually observed with a decrease in the cross-sectional area of the specimen.

The yield strength of plastics in mechanical design

A key property for mechanical designers using plastics is the yield strength, but there is a key caveat to mention. It would seem that the yield strength would be exactly where the plastic becomes inelastic. In reality, due to molecular bonding, the material can sometimes return to its original length after some portion of inelastic deformation. Therefore, it is very common to note the yield strength at a specific strain rate where 0.2% is the most standard. This is commonly referred to as proof stress.

So, an understanding of the mechanical yield strength is paramount in designing with plastics or other materials because of the predictability of the material. Prior to the yield point, the properties are quite predictable. However, after that yield point, the properties become more variable, and confidence in the predictability significantly decreases.

Another key point is that some plastics do not have a yield point. Some plastics only deform in a brittle fashion, meaning their deformation is linearly elastic. Once the maximum strength is attained, the material “fractures.” This is observed in some compounded (fillers/additives/inorganic materials) products and some materials with a very high elastic modulus. This type of failure is observed in composites, as well.

Yield strength of common polymers

The table below gives a comparison of various plastics and other materials of interest.

| Material | Yield Strength (MPa) |

| Polypropylene | 12-43 |

| Nylon 6,6 | 45 |

| High-density polyethylene (HDPE) | 26 - 33 |

| Polyvinyl chloride | 55 |

| Polyvinylidene fluoride | 48 |

| ASTM A36 Steel | 250 |

| Human skin | 15 |

| Bone | 104 - 121 |

| Diamond | 1600 |

| Copper | 70 |

Summary

This article provides a general understanding of some basic mechanical properties of plastics, namely the yield strength. The knowledge of what the yield strength is, physically, will help when designing new parts for a wide array of end uses.

Plastics are being used in more applications each day, and so understanding how the material will react in different environments will be extremely useful in engineering for the future.