Low-Friction Plastic for Optimal Sliding Applications

Murdotec Kunststoffe GmbH & Co. KG

The friction and wear behaviour of contacting materials vary greatly depending on the application in which they are used. Whether it is the applied load, sliding velocity, or change in contacting surfaces, such influences may have a significant impact on the wear performance of a material. This raises the need for solutions that can inherently minimise friction and resist external influences, thus reducing the required driving force and maintenance.

Low-friction plastics are self-lubricating materials with outstanding slide properties, resulting in perfect gliding performance. Here is how such materials stand to be vital solutions in demanding application areas, such as conveyor systems, bearings, and industrial machinery.

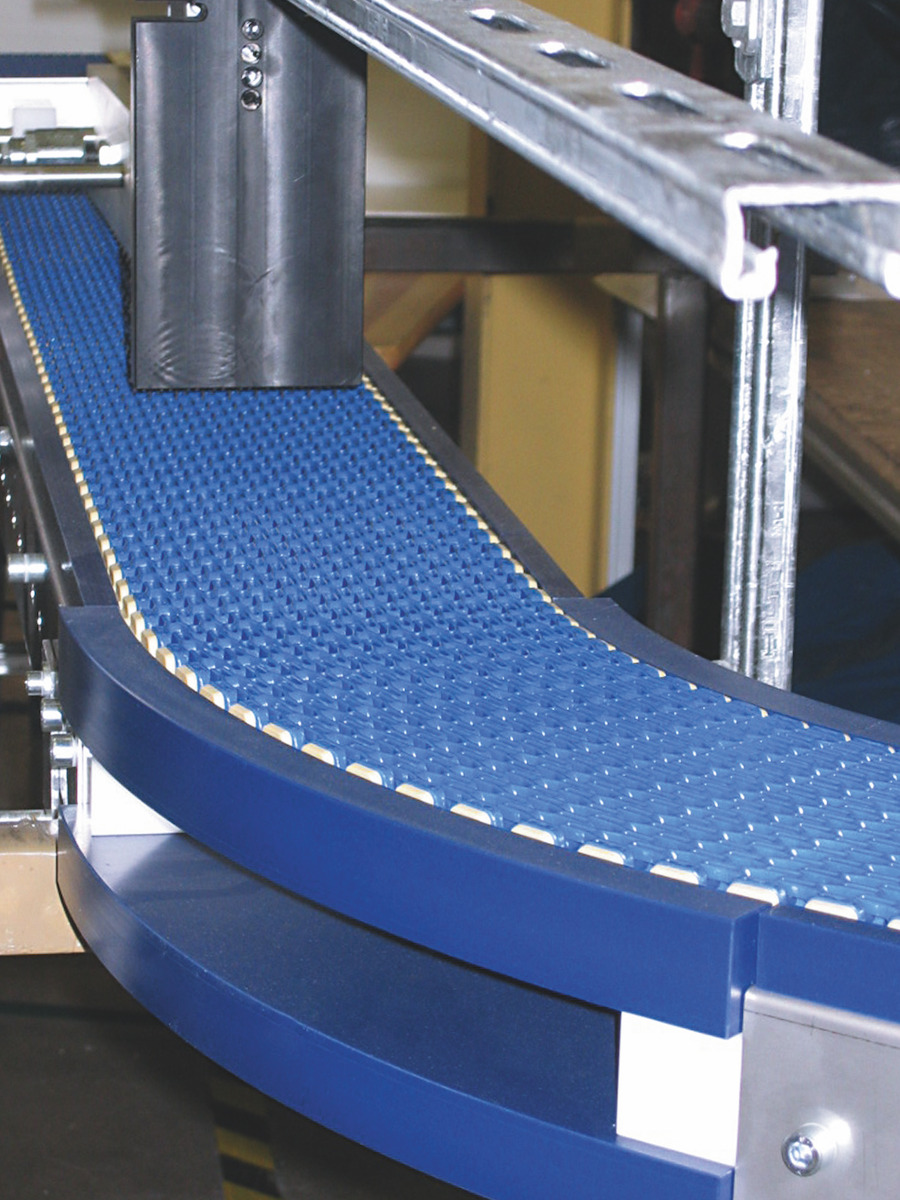

Many industries and application areas require materials with good slide properties that can withstand high loads and continuous contact. Conveying systems, for instance, undergo a wide range of loads under varying conditions, which can highly affect the friction behaviour of the materials. Bearings, rollers, gears, and other automotive parts also demand suitable slide properties and particular mechanical properties, such as high impact resistance.

And the list goes on. Any application area with moving parts would require either sufficient lubrication that can minimise wear and friction or materials with sufficiently good friction properties to maintain their performance and withstand the external influences.

Self-lubricating plastics intrinsically have very low coefficients of friction. With their good anti-adhesion properties, they enable the contacting parts to move smoothly and continuously without falling under the stick-slip effect. With that in mind, Murdotec Kunststoffe has developed a low-friction plastic material as a solution for many operational issues, allowing for perfect gliding optimisation.

Introducing Murdotec® 2000 MC: a self-lubricating plastic

Murdotec® 2000 MC is an ultra-high-molecular-weight polyethylene (UHMWPE) from Murdotec Kunststoffe. UHMWPEs are a family of thermoplastics with high fracture toughness, low friction coefficient, and high resistance to wear and abrasion. They have remarkable tribological characteristics and excellent impact resistance, even at extremely low temperatures, putting them ahead of stainless steel. They are also chemically inert, water-resistant, and good insulators of heat and electricity.

These characteristics have made UHMWPEs suitable materials for a huge variety of applications, particularly those requiring low friction, high durability, and good chemical resistance. Being a self-lubricating material, Murdotec® 2000 MC has found its way into applications as demanding as the displacement and construction of a 60-ton steel bridge.

Murdotec® 2000 MC’s supportive gliding role: a use case

In the town of Erkner, Germany, the railway has been a significant element for a long time. A double-tracked railway bridge crosses the Flakenkanal, a river that passes through the town connecting the two lakes, Flakensee and Dämeritzsee. However, this old timber-framed bridge has suffered from deterioration, and its restoration has been deemed costly.

So, a decision was made to replace it with a new steel-framed bridge. In order to do so, the steel framework had to be transported from the riverbank where it was resting onto a pontoon until it reached its provisional support point on the other side of the river. A hydraulic cylinder pushed forth the framework from the edge of the bank onto the pontoon.

So as to facilitate the displacement of the 60-ton-weighing steel framework, Murdotec® 2000 MC came into play. With its anti-adhesion and self-lubricating properties, Murdotec® 2000 MC played the role of a supportive gliding material, minimising friction and allowing the framework to slide much more easily onto the pontoon.

The steel truss bridge in Erkner, Brandenburg at the time of construction (Clemensfranz, Wikimedia Commons, CC License).

The table below shows key properties and characteristics of Murdotec® 2000 MC that have allowed it to be the material of choice for such an application.

|

Murdotec® 2000 MC (UHMWPE) |

|

|

Key characteristics |

|

|

Self-lubricating |

Good anti-adhesion properties |

|

Very high shock and impact resistance |

Good machinability |

|

No stick-slip effect |

Electrically isolating |

|

General properties |

|

|

Coefficient of friction |

0.1 |

|

Density at 23.0 °C |

0.94 g/cm3 |

|

Moisture absorption at 23.0 °C |

0 % |

|

Mechanical properties |

|

|

Elastic modulus at 23.0 °C |

0.7 GPa |

|

Elongation at 23.0 °C |

250 % |

|

Impact strength, Charpy notched at 23.0 °C |

120 kJ/m2 |

|

Thermal properties |

|

|

Coefficient of thermal expansion at 23.0 °C |

2 x 10-4 1/K |

|

Melting point |

130 - 135 °C |

|

Service temperature range |

-200 °C - 90 °C |

|

Electrical properties |

|

|

Dielectric strength at 23.0 °C |

45 kV/mm |

|

Surface resistivity at 23.0 °C |

1 x 1012 Ω/sq |

|

Volume resistivity at 23.0 °C |

1 x 1012 Ω/cm |

Application areas of UHMWPE - Murdotec® 2000 MC

All these properties mentioned above have enabled this UHMWPE material to find its way into many application areas in different industries, including:

- Slide bars and storage equipment for the food sector in diaries and breweries

- Guides for PET bottle conveyors

- Sliding rails, profiles, and segments

- Gaskets, link belts, crane support plates, and bearing bushes

- Control discs, deflection pulleys, and wear bars

Murdotec® 2000 MC is a material with perfect gliding optimisation. Its sliding properties significantly reduce the required driving force and energy while maintaining a higher slide speed. Consequently, this brings about a lower need for maintenance and higher productivity. All this is the result of Murdotec Kunststoffe’s years of experience in developing and producing high-quality materials.

Murdotec Kunststoffe is a trusted supplier and manufacturer of technical thermoplastics based on polyethylene (PE). They enhance the quality of their PE materials, particularly HMWPE and UHMWPE, via sophisticated recipes that help boost the material properties. Based in Germany, they provide their customers with semi-finished products and advise them on how to best use those products.

Today, Murdotec Kunststoffe have partnered with Matmatch to bring their materials and services one step closer to engineers and product developers searching for high-quality polyethylenes with distinct properties, such as self-lubrication. Their materials are available in sheet and rod forms and have the required quality, safety, and sustainability certifications (ISO 9001:2015, ISO 50001, ISO 14001:2015).

Article by Murdotec Kunststoffe GmbH & Co. KG

Murdotec plastics

Technical plastics for machine construction

Murdotec plastics develops and produces thermoplastics at the most demanding of quality levels.

Highest demands in production and consulting

Everything at Murdotec revolves around polyethylenes. These are subdivided into groups with defined minimum requirements for better distinction and have been named HD-PE, HMW-PE and UHMW-PE.

As a manufacturer based in Germany, we are able to guarantee that our semi-finished products are of the highest quality – thanks to the targeted choice of selected raw materials as well as continuous monitoring during production and the composition of recipes.

We advise our customers in choosing the semi-finished products that offer the desired properties that will suit their needs. But our work does not end with the shipping of the ordered goods. We will work with you on request to develop individual solutions and advise you on the best way to use our semi-finished products.

Top-quality PE

Murdotec only uses HMW-PE- and UHMW-PE-group polyethylene. The quality of a UHMW-PE as per ISO 15527 is largely guaranteed by the basic material and processing parameters. Murdotec significantly improves this quality by using sophisticated recipes from its own laboratory to considerably enhance the plastics’ properties. In addition, EC regulations define application limits by requiring certification as per Regulations (EC) No. 1935/2004 and 10/2011 for plastics that come into contact with foods that have not yet been packaged, for example.

We rely on such innovative production technologies as the latest computer-controlled and monitored press lines and environmentally-safe raw-material handling.

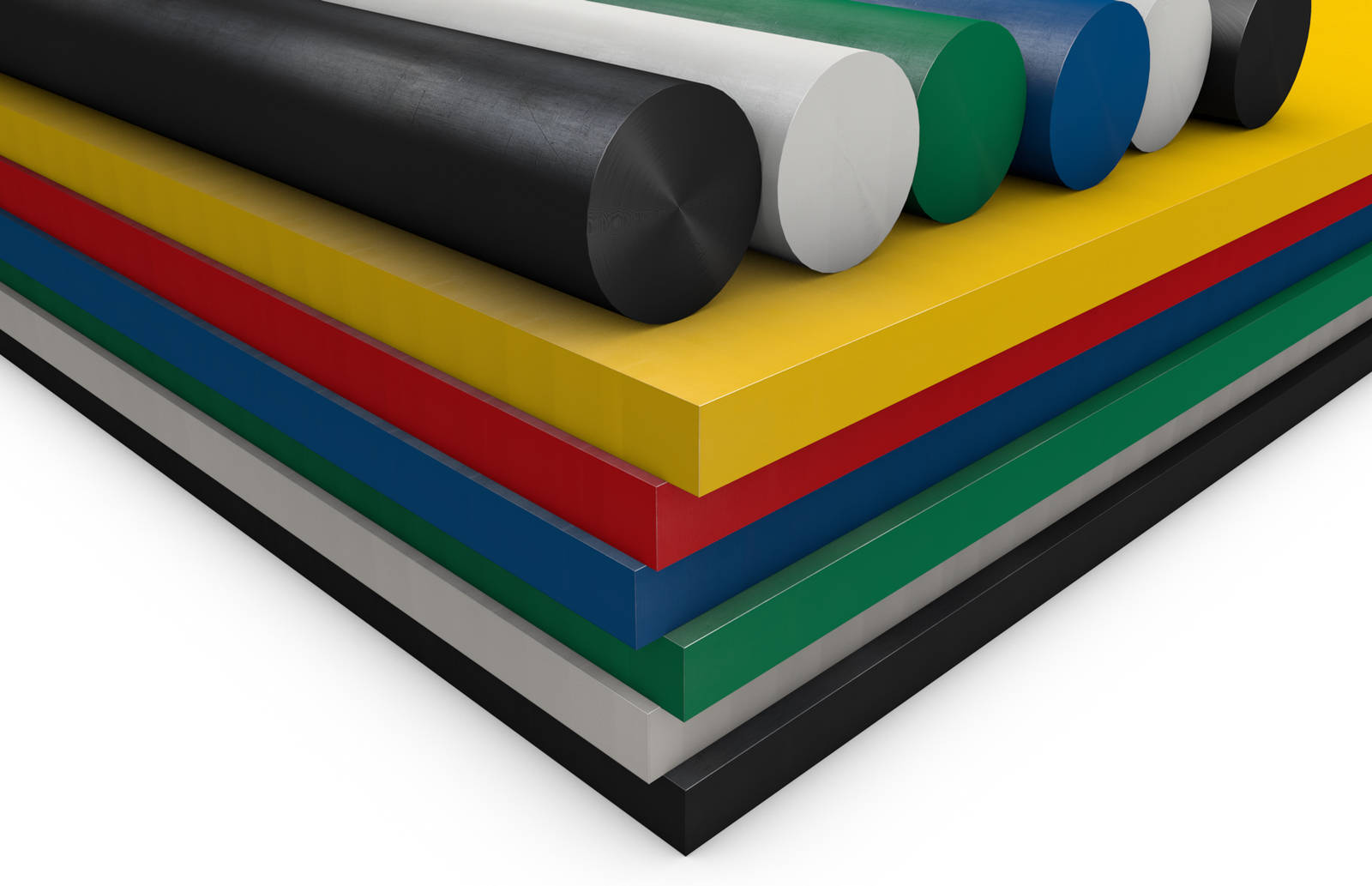

The result is an extensive product range consisting of sheets, pre-cut parts, and rods. Whatever the sector – machine construction, conveyor technology, lining and bulk material handling or the paper, food, or forestry industries – we’ve got the right type of plastic for you!

Suitable plastics for every sector and application

5 reasons for UHMW-PE and HMW-PE from Murdotec

Our technical UHMW-PE materials Murdotec® 1000, and Murdotec® 2000, our technical HMW-PE material Murdotec® 500, and our plastics in the LM family – which are approved for use in the food industry – are even better than semi-finished products as per ISO 15527. Why?

- We only use carefully selected raw materials from renowned suppliers.

- The particle size, particle size distribution, and molecular weight are constantly monitored by our incoming material inspection team.

- Our computer-controlled press lines guarantee optimum heating, pressing, and cooling down phases.

- Through exact compliance with the processing parameters, we ensure a constant production of semi-finished products with a very low level of internal stress.

- Fully-automated mixing lines allow us to supply precisely reproducible material types with clearly defined characteristics.

Our products – customised for you

Find the right sheets, rods, and pre-cut parts with our selection assistants

MURDOTEC® Sheets

Find the needed PE plastic sheets with all necessary information and view the current stock level in your customer area.

https://www.murdotec.de/en/product-range/sheets.html

MURDOTEC® Rods

Find the needed PE plastic rods with all necessary information and view the current stock level in your customer area.

https://www.murdotec.de/en/product-range/rods.html

CUSTOMISE PRE-CUT PARTSMURDOTEC® Pre-cut parts

PE plastics in high quality, quickly available for your use.

https://www.murdotec.de/en/product-range/pre-cut-parts.html

Murdotec® plastics in figures

Here’s what you need to know about our company:

Established in: 2001

Managing Directors: Detlev Höhner, Andreas Balla, Felix Tilse

Headquarters: Dortmund (North Rhine-Westphalia), Germany

Workforce: 50

Turnover: approx. € 15 million

Products / processes: Development, production and sale of thermoplastics (UHMW-PE/PE 1000 and HMW-PE/PE 500), pressed semi-finished products, technical construction plastics

Sectors: Machine construction and plant engineering, construction industry, automotive industry, medical engineering, aerospace industry, oil production, electrical engineering and many other fields of industry.

Production location: Dortmund

MURDOTEC® KUNSTSTOFFE

Premium PE plastics

Industrial PE for top quality requirements

Premium plastics by Murdotec® offer more than a standardised UHMW-PE. They are characterised by their extremely good resistance to chemicals, really high impact strength, and low weight. Are you looking for a versatile technical plastic? We can offer the right solution.

Murdotec® 1000 coloured

Ultra-high molecular polyethylene (UHMW-PE) as per ISO 15527, sheet group 1.2

Murdotec® 1000 coloured, our UHMW-PE, is ideally suited for use where good wear and abrasion resistance along with excellent slide properties are required. This material also has excellent machining properties.

With a molecular weight of around 5 million g/mol, this plastic always meets top quality requirements and is also approved by the EU and FDA.

This material is quickly available in lots of RAL colours.

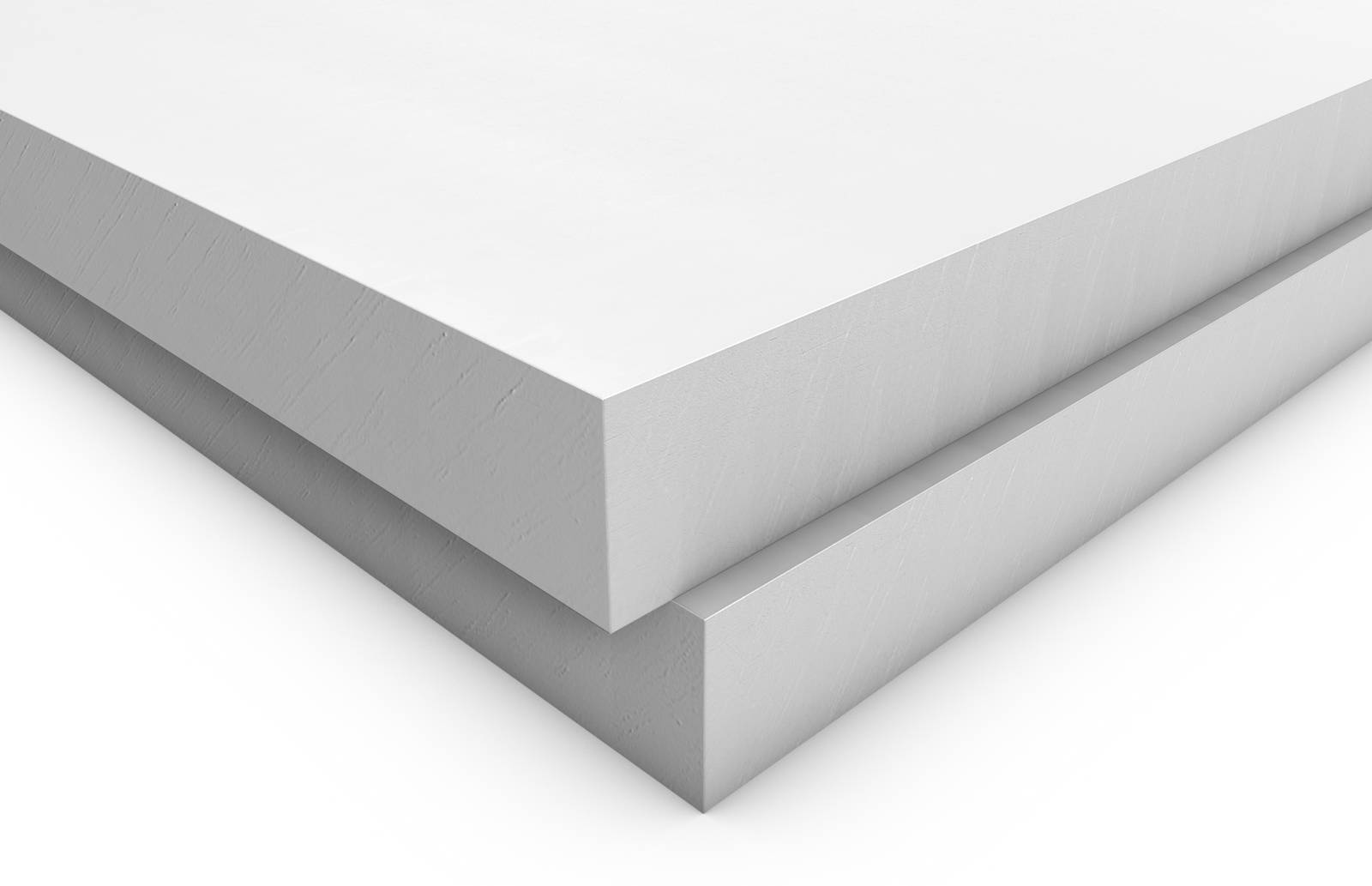

Murdotec® 500 natural

High molecular polyethylene (HMW-PE) as per ISO 15527, sheet group 2.1

Murdotec® 500 natural, our HMW-PE, is particularly suited for use in the food sector. This material has a molecular weight of around 500,000 g/mol and is characterised by extremely good cut resistance at the same time as having good slide properties. This plastic also has high wear resistance.

Manufactured using state-of-the-art presses, this material ensures top quality, and is approved by the EU and FDA.

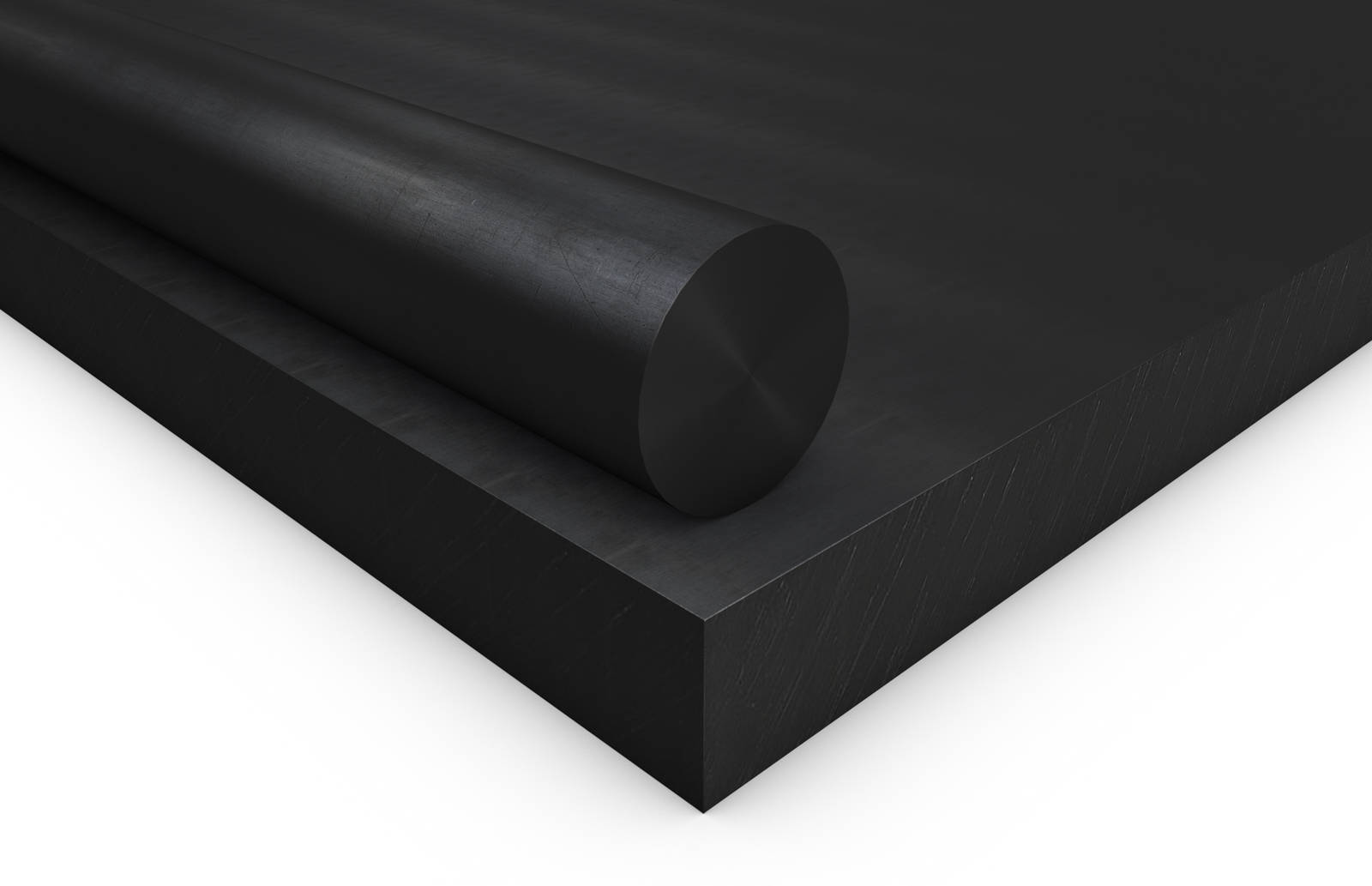

Murdotec® 2000 black AST

Ultra-high molecular polyethylene (UHMW-PE) as per ISO 15527, sheet group 1.1

Murdotec® 2000 black AST, our UHMW-PE with antistatic properties, is the right plastic if you need particularly good wear resistance. In environments where the material is exposed to extremely high stresses and antistatic properties are required, Murdotec® 2000 Black AST is the ideal choice.

Thanks to its molecular weight of 9 million g/mol, it has an even higher abrasion resistance than Murdotec® 1000.

Downloads

Brochure

- Murdotec: Your specialist for engineering plasticsPDF, 289 KB

- Murdotec: Dialen® - Solutions for bulk materialsPDF, 2 MB

- Murdotec: Market sectors for our engineering plasticsPDF, 447 KB

- Murdotec: Properties of our plasticsPDF, 1 MB

- Murdotec: resistance measurementPDF, 126 KB

Technical data

Murdotec® premium plastics

- Murdotec 1000 green - data sheetPDF, 60 KB

- Murdotec 1000 black AST - data sheetPDF, 60 KB

- Murdotec 1000 natural - data sheetPDF, 60 KB

- Murdotec 1000 coloured - data sheetPDF, 60 KB

- Murdotec 500 green - data sheetPDF, 61 KB

- Murdotec 500 black AST - data sheetPDF, 60 KB

- Murdotec 500 natural - data sheetPDF, 60 KB

- Murdotec 500 coloured - data sheetPDF, 60 KB

- Murdotec 2000 green - data sheetPDF, 61 KB

- Murdotec 2000 black AST- data sheetPDF, 60 KB

- Murdotec 2000 natural - data sheetPDF, 60 KB

- Murdotec 2000 coloured - data sheetPDF, 60 KB

Murdotec® special plastics

- Murdotec 2000 MC - data sheetPDF, 60 KB

- Murdotec 2000 MCE - data sheetPDF, 59 KB

- Murdotec 2000 MCWE - data sheetPDF, 59 KB

- Murdotec 2000 MOS - data sheetPDF, 327 KB

- Murdotec 2000 MD - data sheetPDF, 60 KB

- Murdotec 2000 G - data sheetPDF, 60 KB

- Murdotec 2000 HS - data sheetPDF, 327 KB

- Murdotec 2000 E - data sheetPDF, 60 KB

- Murdotec 1000 E - data sheetPDF, 60 KB

- Murdotec 1000 light grey AST - data sheetPDF, 531 KB

- Murdotec 1000 white ESD - data sheetPDF, 205 KB

- Murdotec 1000 ST- data sheetPDF, 524 KB

- Murdotec 1000 AB - data sheetPDF, 60 KB

- Murdotec 500 AB - data sheetPDF, 60 KB

- Murdotec 500 ICE - data sheetPDF, 61 KB

Murdotec® regenerated plastics

- Murdotec 1000 U green - data sheetPDF, 60 KB

- Murdotec 1000 U black AST - data sheetPDF, 60 KB

- Murdotec 1000 U black-multicoloured - data sheetPDF, 60 KB

Dialen®

- Dialen MR opalgreen - data sheetPDF, 61 KB

- Dialen MR black AST - data sheetPDF, 61 KB

- Dialen MR natural - data sheetPDF, 61 KB

Product handling information

- Dialen MR black AST - product handlingPDF, 73 KB

- Dialen MR natural - product handlingPDF, 73 KB

- Dialen MR opal green - product handlingPDF, 73 KB

- Murdotec 500 AB - product handlingPDF, 71 KB

- Murdotec 500 black AST - product handlingPDF, 71 KB

- Murdotec 500 green - product handlingPDF, 71 KB

- Murdotec 500 ICE - product handlingPDF, 73 KB

- Murdotec 500 natural - product handlingPDF, 71 KB

- Murdotec 1000 AB - product handlingPDF, 73 KB

- Murdotec 1000 black AST - product handlingPDF, 71 KB

- Murdotec 1000 E - product handlingPDF, 71 KB

- Murdotec 1000 green - product handlingPDF, 71 KB

- Murdotec 1000 light grey AST - product handlingPDF, 71 KB

- Murdotec 1000 natural - product handlingPDF, 71 KB

- Murdotec 1000 ST - product handlingPDF, 38 KB

- Murdotec 1000 traffic blue - product handlingPDF, 73 KB

- Murdotec 1000 traffic yellow - product handlingPDF, 73 KB

- Murdotec 1000 U black-multicoloured - product handlingPDF, 71 KB

- Murdotec 1000 U black AST - product handlingPDF, 71 KB

- Murdotec 1000 U green - product handlingPDF, 71 KB

- Murdotec 1000 white ESD - product handlingPDF, 73 KB

- Murdotec 2000 black AST - product handlingPDF, 73 KB

- Murdotec 2000 blue - product handlingPDF, 180 KB

- Murdotec 2000 E - product handlingPDF, 71 KB

- Murdotec 2000 green - product handlingPDF, 73 KB

- Murdotec 2000 G - product handlingPDF, 71 KB

- Murdotec 2000 HS - product handlingPDF, 71 KB

- Murdotec 2000 MCE - product handlingPDF, 71 KB

- Murdotec 2000 MCWE - product handlingPDF, 77 KB

- Murdotec 2000 MC - product handlingPDF, 71 KB

- Murdotec 2000 MD - product handlingPDF, 71 KB

- Murdotec 2000 MOS - product handlingPDF, 71 KB

- Murdotec 2000 natural - product handlingPDF, 73 KB

- Murdotec 2000 red - product handlingPDF, 180 KB

- Murdotec 2000 yellow - product handlingPDF, 181 KB