3D Printing Glass Structures with Soda-lime and Borosilicate Glass

SCHOTT AG - Glass Tubing

As 3D printing continues to be considered the rising technology of today, one aspect that has been significantly growing is the materials used. With polymers and metals becoming mainstream, one material is gradually entering the playing field with great potential. This material is glass. SCHOTT, a global leader in manufacturing glass tubes, rods, and profiles, has already been providing borosilicate glass and soda-lime glass to 3D printing companies, supporting the evolution of this industry.

The 3D printing industry in the last decade has grown considerably with a market size of almost USD 10 billion in 2018, projected to continue the trend to reach upwards of USD 34 billion in 2024. This growth has been boosted with the shift in 3D printing applications from prototyping to manufacturing functional parts. With the printing material accounting for 10-30% of the market, it is only essential to look into what options there are for such materials and study their properties and limits.

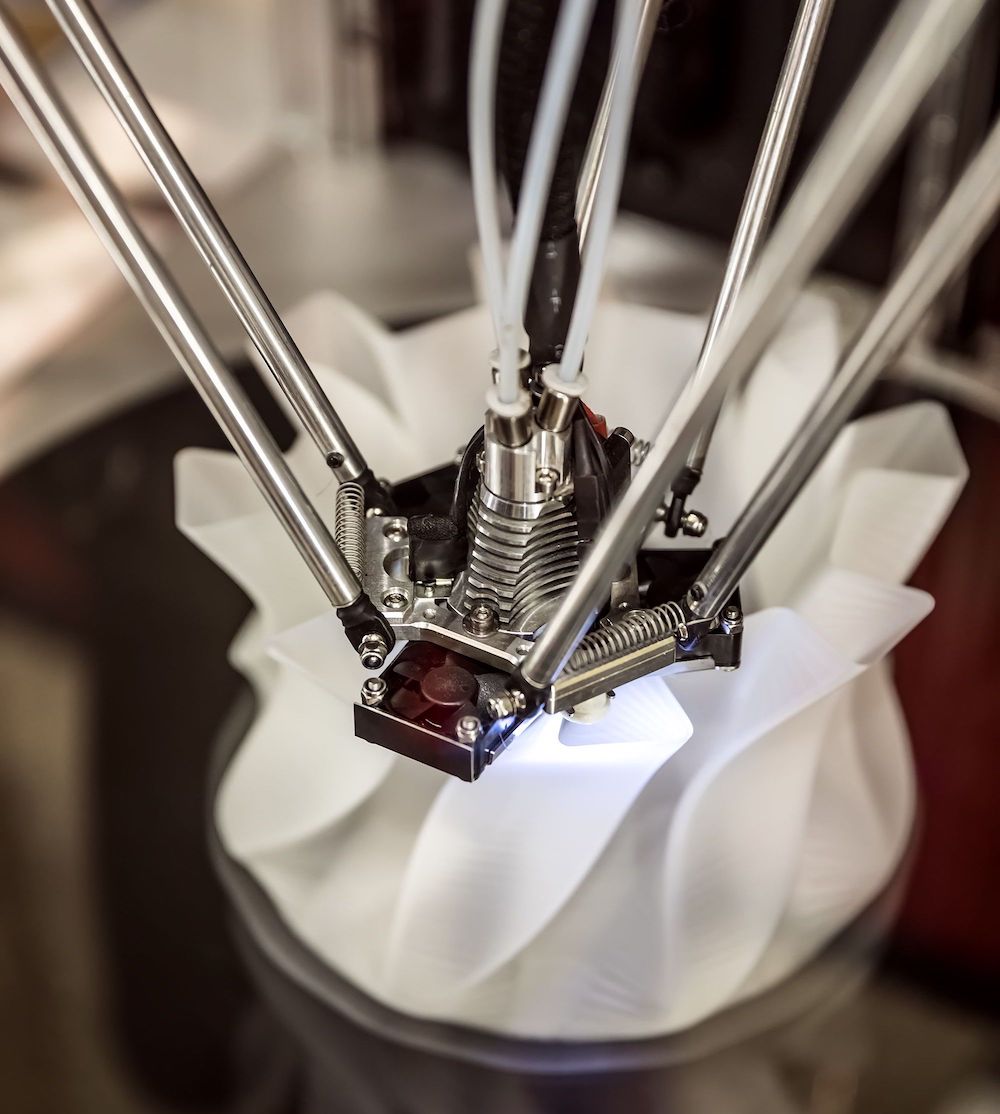

Figure 1. 3D printing of a complex-shape part layer-by-layer.

Glass as a 3D printing material

3D printing has incorporated many materials into its printing materials arsenal; most common are plastics and metals. Glass, on the other hand, and its corresponding printing machines have only entered the early stages of the game.

Despite being used as a filler material in plastic 3D printing, glass remains a challenging material with which to work. However, innovation in materials science and additive manufacturing (AM) has allowed researchers and companies to venture into this line of work and test the properties and possible outcomes of glass as printing material.

With 3D printing targeting aspects like freedom of design, personalisation, and functional integration, glass exhibits significant potential for a wide range of AM applications thanks to its key properties. These include optical features, chemical resistance, mechanical and thermal stability, availability and cost-effectiveness.

Glass can be printed in different ways. Some of the suitable AM methods for glass printing include powder bed fusion, binder jetting, material extrusion, and sheet lamination. Powder bed fusion uses thermal energy to fuse particular areas of a glass powder bed in a selective manner. Similarly, binder jetting involves the deposition of a liquid bonding agent onto a powder bed to selectively bind together the glass powder. In material extrusion, glass is dispensed through a nozzle, where it is heated, to be printed layer-by-layer. Sheet lamination, on the other hand, includes the bonding of thin sheets of glass in a layered manner to form a single three-dimensional part.

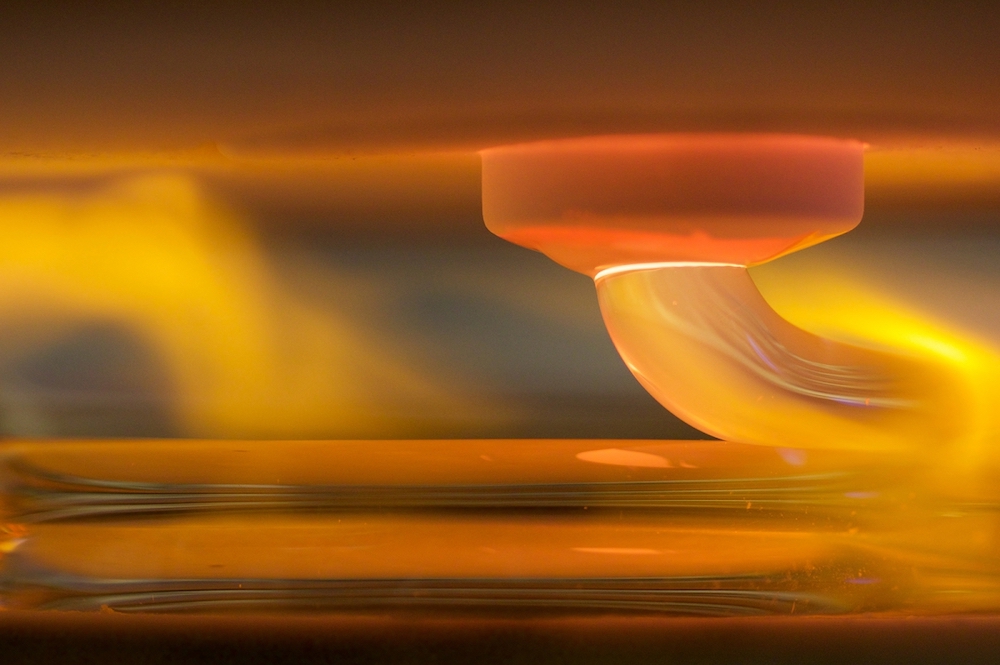

Figure 2. The glass 3D printing process. Credits: Steven Keating, MIT.

The works of scientists

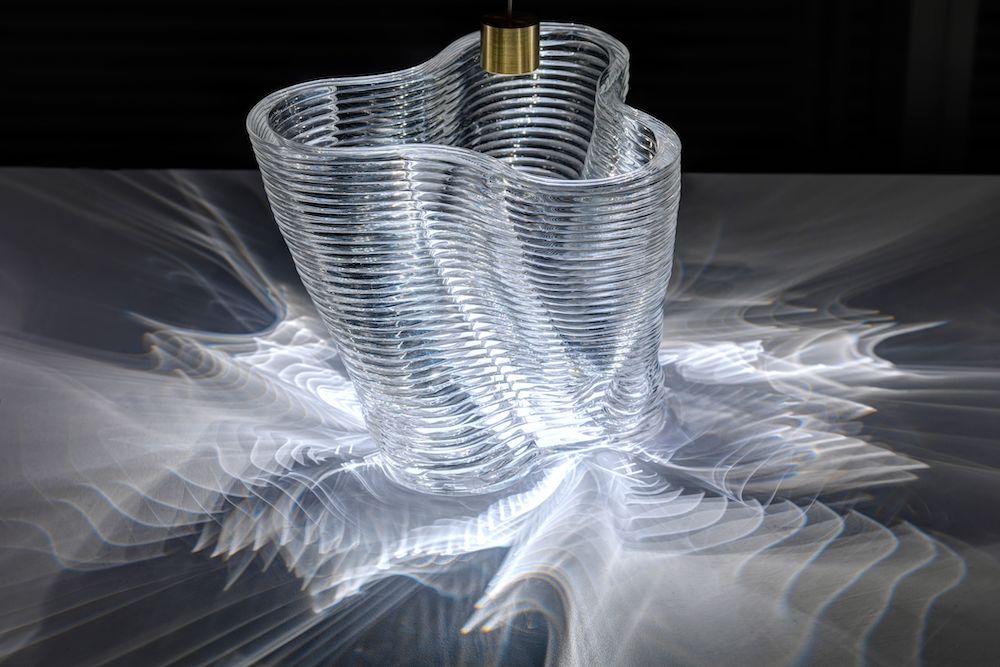

Researchers at the MIT Mediated Matter group revealed their work on developing a novel AM methodology, called G3DP (Glass 3D Printing), with which they were able to heat glass up to high temperatures, melt it, and then use it as a 3D printing material. This method was quite impressive, only to be followed by their second iteration, G3DP2, which gave rise to high geometric complexity, accuracy, and strength of 3D printed glass.

Many applications could be potential areas for 3D printed glass not only to be used in but also to stand out as a new material brought about by an exciting technology. These applications include arts, architectural designs, science, and particular optical products such as gradient lenses.

Contributions from industry leaders

SCHOTT, a leading manufacturer of glass tubes, rods, and profiles, has been providing 3D-printing projects with high-quality borosilicate and soda-lime glass, which exhibit high physical properties. SCHOTT believe glass printing will be a supplement to traditional production techniques in the medium term. “First and foremost, we see ourselves as a supplier of special materials with the typical properties of glass in powder, rod, and sheet form, which are also suitable for 3D printing,” said Bernd Hoppe, head of the laser- and post-processing in the R&D department at SCHOTT. Some of SCHOTT’s high-quality glass materials include AR-GLAS® and DURAN® tubing materials. These are soda-lime silicate and borosilicate glass materials, respectively.

The wide range of materials and forms that SCHOTT provides, including glass powder, tubing, rods, and pastes, is an ideal starting point for companies to utilise glass as print material, even in demanding applications.

Figure 3. 3D printed glass prototype from the G3DP project. Credits: Andy Ryan, MIT.

The right material for the job

Novel technologies, such as glass 3D printing, could only be realised with the right materials. Material selection is a fundamental step, and finding the right material is no easy task. Luckily, major material suppliers, like SCHOTT Glass Tubing, provide a broad spectrum of high-quality glass materials with a production capacity of over 155K tons of glass tubing. They have listed their materials here on Matmatch to ensure that engineers, researchers, and product developers can easily find their desired materials and reach out to them directly.

Visit the SCHOTT Glass Tubing supplier page for more information on their materials and to get in direct contact with them.

Article by SCHOTT AG - Glass Tubing

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment.

With a production capacity of more than 150,000 tons of glass tubing and production sites in Europe, South America and Asia, SCHOTT Tubing is one of the world’s leading manufacturers of glass tubes, rods and profiles. Approximately 60 glass types are produced in several outside diameters and in a variety of lengths based on site-overlapping strategies in development, production and quality assurance. SCHOTT Tubing provides customized products and services for international growth markets such as pharmaceuticals and electronics as well as industrial and environmental engineering.