Flexible Campaign Melting Paving the Way for Specialty Glass

SCHOTT AG - Glass Tubing

Specialty glass production has been on the rise, given the new demands that are emerging through modern technology. With niche markets requiring a sustainable supply of customised, high-quality glass, it is rather essential to develop the right solutions and upgrade conventional glass production processes in order to fulfil those requirements in a time- and cost-effective manner. One solution called “flexible campaign melting” has been introduced by SCHOTT Tubing, which allows for on-demand production of specialty glass. So, what is specialty glass? And how does flexible campaign melting help niche markets?

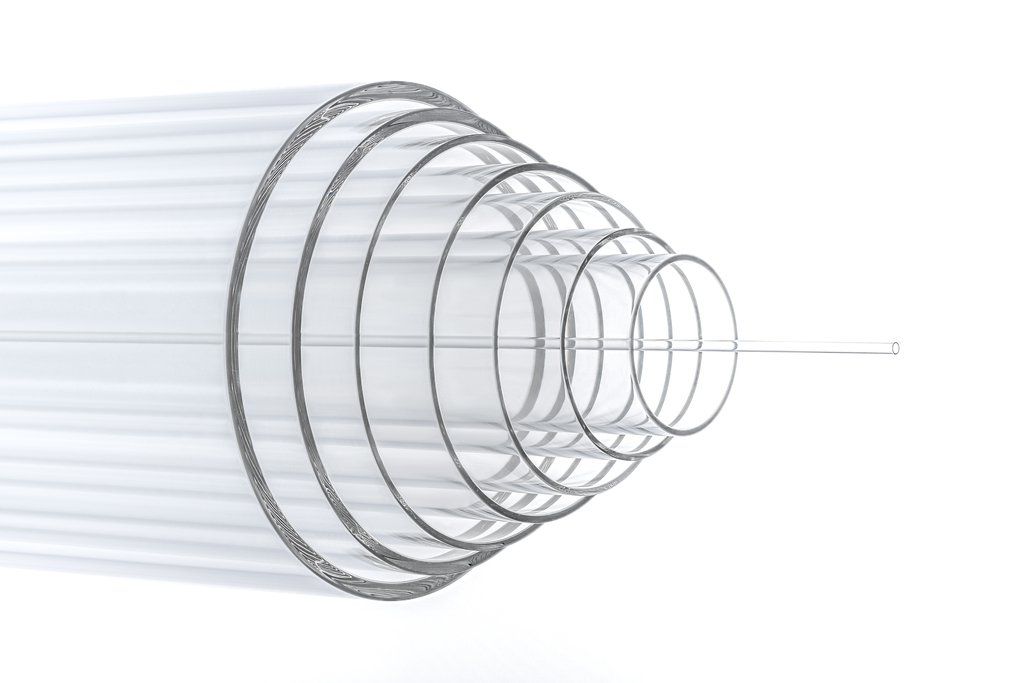

Figure 1. The different dimensions of DURAN® glass tubing from SCHOTT AG.

Glass production, in general, is a process that involves the sequential steps of mixing raw materials and melting them at high temperatures to reach a fused state, after which they were drawn or floated to form the desired end products. However, in many cases, the production of certain glass products has been significantly reduced and sometimes even brought to an end due to a major drop in demand with the rise of alternative products.

One example is the lighting industry, which had utilized Barium glass as the standard material for their lamp housings until LEDs were introduced. As a result, such glass housings were not sought-after anymore, and the production process has been mostly discontinued. This halt has created problems for other smaller industries that utilise the same kind of glass, just as the producers of pH electrodes, for instance. As a niche market, their need for relatively small quantities of barium glass is not sufficient for a possible resumption of the fully continuous production process. In addition, they do not have a practical option to substitute it with an alternative material due to the tight requirements they have in terms of glass properties. Such an issue urges for new solutions that can provide the required material without the need for a large-scale production process, and thus, can minimize the relative time and cost.

What is specialty glass?

Specialty glass denotes the various types of glass products that take place in manufacturing and further processing. They are distinct from standard glass through enhanced material properties that are particularly tailored for the material to operate in diverse conditions. For instance, many types of specialty glass exhibit exceptional chemical durability, which allows them to operate properly in corrosive environments or under extreme conditions. Such types of specialty glass include borosilicate glass, aluminosilicate glass, and Kovar sealing glass.

One example of specialty glass is DURAN® tubing from SCHOTT Tubing, which is a heat resistant material that is able to withstand corrosive gases. This borosilicate glass material also has a high resistance to thermal shocks and is a strong electrical insulator, which allows it to be used in various application areas, including heat exchangers, fuses, x-ray tubes, and safety lighting, to name a few. Other similar materials include DUROBAX® amber, which is known for its hydrolytic resistance and light protection both in the visible and ultraviolet (UV) range, aluminosilicate glass 8252, which is useful under extremely high temperatures, and Kovar glass 8250, which allows for impermeable sealing to Kovar alloy.

Nonetheless, for such specialty glass materials to be sufficiently produced, particularly for the niche sections of the industry, certain improvements to the production processes are needed. One viable solution offered by SCHOTT Tubing takes place in the melting stage of the production process, and it is appropriately called flexible campaign melting.

Flexible campaign melting

The value of flexible campaign melting lies in its sustainable on-demand supply of the desired specialty glass that, as Dr. Andre Petershans – Product Manager for SCHOTT specialty tubing - explains, “would otherwise be impossible or no longer exist – despite being wanted, even needed, in their mature markets.” Flexible campaign melting is a solution that allows for the simultaneous combination of needs of multiple customers, as a particular glass material is melted on demand for one customer while considering the nearest following melt. This approach not only provides the necessary materials for the customers, but it also brings about great adaptability and versatility in a conventionally inflexible continuous production process.

Solutions as such are game-changers when it comes to the many facets of specialty glass supply. Knowing that glass melting is nothing shy of a complex, painstaking, costly process, supplying niche markets that have relatively low volume needs can be quite challenging. That is why the ability to reach the minimum volume for a melting campaign could prove very effective, and that is what SCHOTT Tubing are offering with flexible campaign melting.

SCHOTT Tubing is a leading manufacturer of glass tubes, rods, and profiles, with a material portfolio of seventy different types of specialty glass, each with its unique and effective material properties. Such a variety allows for the customisation of different products with an assortment of diameters and lengths based on corresponding strategies in production and quality assurance. They have listed their materials here on Matmatch to ensure that engineers, researchers, and product developers can easily find their desired materials and reach out to them directly.

Visit the SCHOTT Tubing supplier page for more information on their materials and to get in direct contact with them.

Figure 2. Flexible campaign melting allows for on-demand specialty glass.

Article by SCHOTT AG - Glass Tubing

SCHOTT is a leading international technology group in the areas of specialty glass and glass-ceramics. The company has more than 130 years of outstanding development, materials and technology expertise and offers a broad portfolio of high-quality products and intelligent solutions. SCHOTT is an innovative enabler for many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT strives to play an important part of everyone’s life and is committed to innovation and sustainable success. The parent company, SCHOTT AG, has its headquarters in Mainz (Germany) and is solely owned by the Carl Zeiss Foundation. As a foundation company, SCHOTT assumes special responsibility for its employees, society and the environment.

With a production capacity of more than 150,000 tons of glass tubing and production sites in Europe, South America and Asia, SCHOTT Tubing is one of the world’s leading manufacturers of glass tubes, rods and profiles. Approximately 60 glass types are produced in several outside diameters and in a variety of lengths based on site-overlapping strategies in development, production and quality assurance. SCHOTT Tubing provides customized products and services for international growth markets such as pharmaceuticals and electronics as well as industrial and environmental engineering.