Precious Metal Alloys for Electrical Contacts

Heraeus

Precious metal alloys are alloys made up of two or more of the elements silver, gold, platinum, palladium, iridium, osmium, rhodium, and ruthenium. Occasionally non-precious metal alloying elements are also used. They are particularly useful materials for electrical contacts as they have a very high electrical conductivity, are highly corrosion-resistant, have good mechanical properties and are machinable.

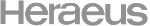

Figure 1. Switching contacts. Credit: Heraeus.

Why use precious metal alloys for electrical contacts?

Silver, gold and the platinum group metals are often used as electrical contacts because of their high electrical conductivity. However, using these metals in electrical contacts has some drawbacks, including poor mechanical properties, leading to poor wear resistance. Some precious metals, e.g. silver, are also prone to chemical degradation, which reduces their electrical conductivity.

To overcome the issues faced by using pure precious metals, they are often alloyed with other metals, including other precious and non-precious metals. This solves some of the limitations of using precious metals as electrical contacts. By alloying, the mechanical properties and corrosion resistance of precious metals can be enhanced, making them better suited for use in a broad range of electrical contact applications.

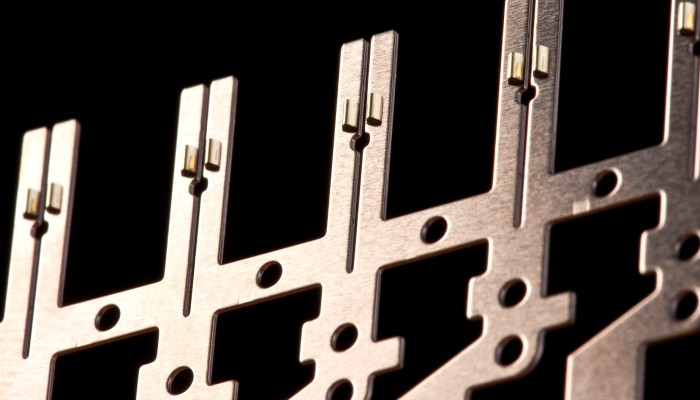

Figure 2. Multi-wire Wipers. Credit: Heraeus.

Properties of precious metal alloys for electrical contacts

Electrical contacts, in general, require high electrical conductivity, corrosion resistance and, in the case of moving contacts such as switches, brushes or slip rings, good mechanical properties and wear resistance.

The properties of precious metal alloys which make them attractive as metal contacts over non-alloyed precious metals include:

- High corrosion resistance

- High electrical conductivity

- Low contact resistivity

- Good machining properties

- Highly reproducible material properties

- High ductility

- High wear resistance

- Long service life

Examples of precious metal alloys for electrical contacts

There are three common groups of precious metal alloy used for electrical contacts. These are silver-based, gold-based and platinum group-based alloys, the latter most commonly being platinum-based and palladium-based alloys.

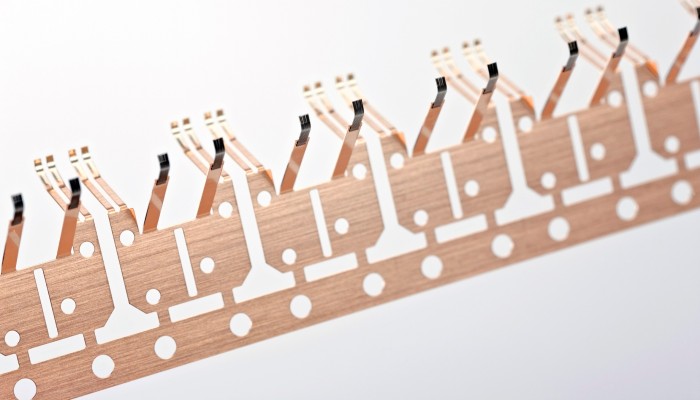

Silver-based alloys

Silver is attractive as a contact material as it exhibits the highest electrical and thermal conductivity of any metal. It also has a strong resistance to oxidation. Its downsides, however, are low wear resistance, low softening temperature and its strong affinity to sulfur. The formation of a silver sulfide layer on the surface of the silver leads to an increase in its electrical resistance.

Through alloying, mechanical properties such as hardness and tensile strength can be improved in order to enhance wear resistance and erosion resistance. This comes, however, at the cost of lower bulk electrical resistivity and corrosion resistance.

The most common alloying element used is Cu, however, Ni is also used.

An example of a silver-based alloy is AgCu20, which is composed of 80 wt.% Ag and 20 wt.% Cu.

Figure 3. Silver-based contact materials. Credit: Heraeus.

Gold-based alloys

Gold is the most chemically stable metal; however, it is not a suitable contact material in its pure form. This is because of its tendency to stick and cold-weld, even with low contact force. It has low hardness and low wear resistance. In its pure form, gold contacts are limited to electroplated or vacuum-deposited coatings.

In most cases where gold electrical contacts are present, gold alloys are used. Binary gold alloys are the most common and typically show increased mechanical strength and electrical switching properties, however, show a reduced electrical conductivity. In order to reduce the gold content, a third element can be added to create ternary alloys. These exhibit good mechanical stability and corrosion resistance.

Common alloying elements in binary and ternary gold-based alloys include the precious metals Pt, Pd, Ag and non-precious metals Ni, Co, and Cu.

Examples of gold-based alloys are AuAg25Cu5 (composed of 70 wt.% Au, 25 wt.% Ag and 5 wt.% Cu), Hera 238 (AuAgCu) and Hera 277 (AuPdAg).

Figure 4. Slip rings. Credit: Heraeus.

Platinum group-based alloys

These alloys have one of the platinum group metals (Pt, Pd, Rh, Ru, Ir, and Os) as their base metal, the two most common being platinum and palladium. Pt and Pd have similarly high corrosion resistance to gold. Their downsides in their pure forms, however, come from their properties as chemical catalysts. Organic compounds deposited on the surface of the metals tend to become polymerised, which forms a brown powder. This leads to increased contact resistance.

Addition of alloying elements to Pt and Pd, similarly to other precious metal alloys, enhances the mechanical properties and corrosion resistance. Of the two, Pd-based alloys are more common. PdAg alloys, for example, exhibit resistance to sulfide formation. The ability of Pd-based alloys to undergo hardening processes makes them particularly useful in wear-resistant sliding contacts.

Platinum group metals are typically alloyed with other metals from the same group as well as Au, Ag, Cu, W, Ni, Co and Zn.

Examples of alloys include Hera 649 (PdAgCu alloy) Age-Hardened and Hera 648 (PdAgCuPtAu alloy) Age-Hardened.

Figure 5. Collector brushes. Credit: Heraeus.

Types of electrical contacts

Precious metal alloys for contacts come in various forms. These include:

- Precious metal strips, used as source material for contact parts such as battery contacts, sealing strips, sliding contacts, or probe needles for testing semiconductor wafers.

- Contact pins, used for signal and power transmission in assembly and joining technology and sensor technology.

- Sliding contacts, such as commutator brushes and commutator angles, used for example in DC motors.

- Switching contacts, commonly used for contact systems in information and data technology.

- Slip rings, used for transferring electrical power and information between stationary and a rotating component.

- Multi-wire wipers, used in contact systems with high current transmission quality.

Which applications are precious metal alloy contacts used in?

There is a wide variety of industries in which precious metals are used for electrical contact applications. These include the automotive, semiconductor, energy, electrical component and medical industries, amongst others.

Some specific applications where precious metals are used for electrical contacts include:

- Switching contacts

- Electric motors and generators, specifically brushes and precision DC motors

- Signal transmission

- Power transmission

- Assembly and joining technology

- Sensor technology

- Medical technology

- Electronic or mechatronic systems

- Radar equipment

- Robotics

- Contacts for hearing aid batteries

- Probe needles for semiconductor wafer testing

- Plug-in connectors for safety components in the automotive industry and for industrial applications such as white goods

- Sealing elements for lambda probes in the automotive industry

- In measurement and control technology as rotating, sliding, and trimming potentiometers

- As position indicators in linear or angular position transmitters

- In automotive technology as contact elements in fuel gauges, oil pressure indicators, and in position transmitters for butterfly valves, steering wheels, accelerator pedals, and gear levers

- Coding switches in rescue service technology, communications technology, and defence technology

- As sliding switches in information electronics

- For transmission of signals or electrical current between moving parts in slip ring systems or in small DC motors

- Switching equipment in the area of low voltage energy technology

- Cranes

- Rotating production machines

- Medical equipment

Figure 6. Multi-wire wipers in use. Credit: Heraeus.

Sourcing precious metal alloys for electrical contact applications

When it comes to sourcing precious metal alloys, quality is of huge importance. It is important to choose a supplier of precious metal alloys, which can deliver high purity. One of the leading precious metals suppliers today is Heraeus.

Heraeus provides precious comprehensive expertise in the precious metal loop – from trading to precious metal products to recycling. The product range varies from contact products, PGM-fabrications and semi-finished materials to high-tech materials and compounds. Their fields of application are sliding and switching contacts, spark plugs, bushings, glass tools, labware, wires and materials for probe needles as well as master alloys, TC-balls, pen points and irradiation sources.

If you’re interested in sourcing precious metal alloys for your application, get in touch with Heraeus right here on Matmatch.

Artikel von <a href=/suppliers/hera-heraeus> Heraeus </a>Heraeus

A globally leading technology group, Heraeus is headquartered in Hanau, Germany. Founded in 1851, it is a family-owned portfolio company which traces its roots back to a pharmacy opened by the family in 1660. Today, Heraeus combines businesses in the environmental, energy, electronics, health, mobility and industrial applications sectors.

The Global Business Unit Heraeus Precious Metals is a leading provider of precious metal services and products. We combine all activities related to our comprehensive expertise in the precious metal loop – from trading to precious metal products to recycling.

The business line Functional Materials is an expert for mechanical processing of precious metals and their alloys. The product range varies from contact products, PGM-fabrications and semi-finished materials to high-tech materials and compounds. Their fields of application are sliding and switching contacts, spark plugs, bushings, glass tools, labware, wires and materials for probe needles as well as master alloys, TC-balls, pen points and irradiation sources.