Graphitised Microballoons as Functional Additives to Produce Superior Composite Materials

SGL Carbon

The aerospace industry is one of many industries that have high and challenging demands when it comes to material properties. For example, in addition to being lightweight – thus lowering the fuel consumption – aerospace materials have to have the highest standards of safety and mechanical stability. For that, companies seek to find solutions that would strengthen their materials while keeping them lightweight, in addition to improving their thermal and chemical properties. One solution that has been put into effect is the use of microballoons. These are filler materials designed as special function additives. SGL Carbon, a world-leading developer and producer of carbon-based solutions, are already providing graphitised microballoons for use in various composite materials. So, what are these microballoons, how do they work, and what effects do they have on materials?

Microballoons, also known as microspheres, are hollow spheres of microscopic dimensions that are used as additives to materials, bringing about a modification in their properties. The size of these spheres varies depending on the purpose of use, ranging from single micrometres up to thousands of micrometres. They can be made of different materials resulting in different outcomes, such as reduction in density, increase in dimensional stability, and improvement in strength.

The effects of microballoons

Microballoons are essentially lightweight spheres that once integrated into composite parts would render the parts lightweight without minimising their strength. Hence, they lead to an increased strength-to-weight ratio.

These low-density fillers can also significantly enhance the material’s high-temperature and chemical resistance. They are compatible with various materials. Other properties that microballoon addition can affect include dielectric properties, surface properties, and thermal properties.

Graphitised microballoons are carbon-based microspheres designed as functional additives particularly for polymeric materials, such as epoxy, polyurethane, polyester, and phenolic resin composite materials. The resulting material is referred to as syntactic foam.

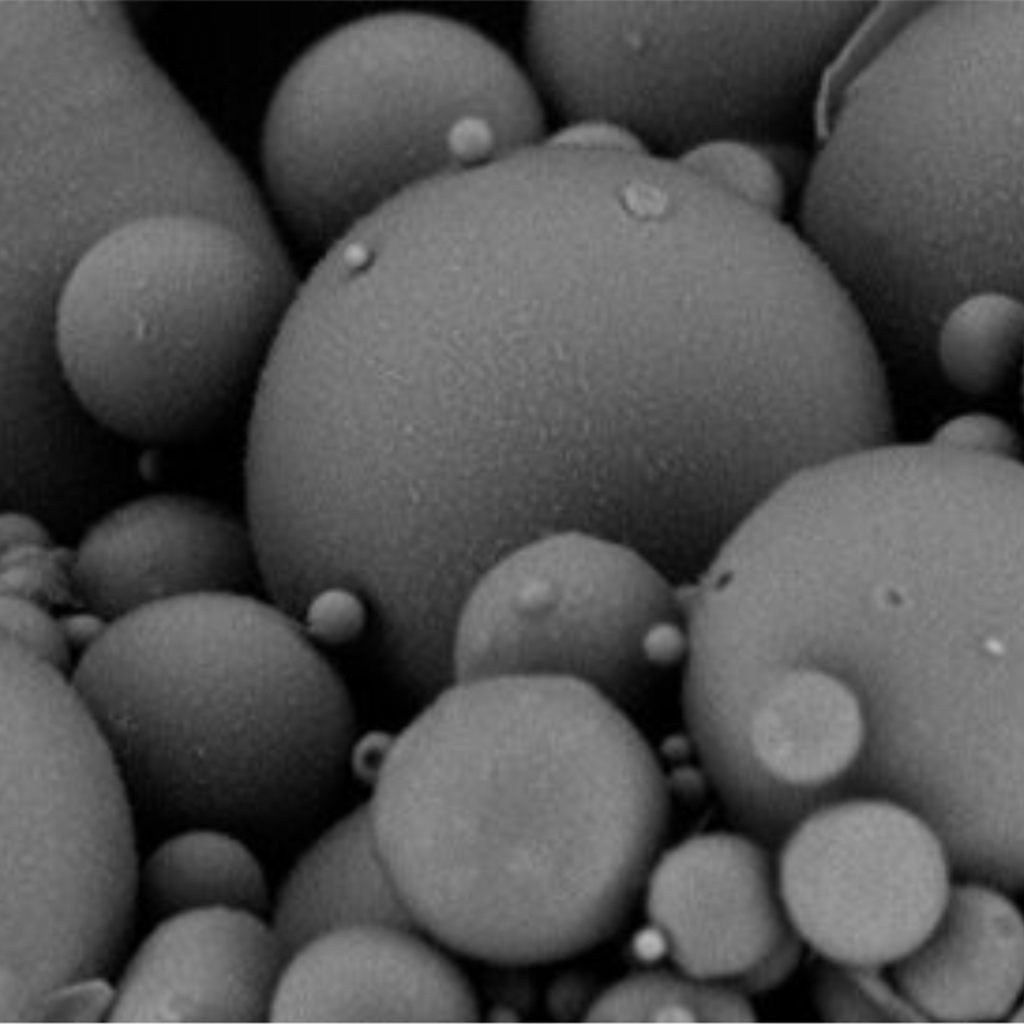

Figure 1. SEM image of graphitised microballoons (SIGRATHERM®). Courtesy of SGL Carbon.

Properties of graphitised microballoons

SIGRATHERM® microballoons by SGL Carbon are graphitised microballoons used to generate low-density syntactic foams that have high levels of thermal protection and insulation. They show excellent resistance to high temperatures, reaching up to 500ºC (932ºF) in air medium or 3000ºC (5432ºF) in inert gases or vacuum.

Their exceptional temperature resistance enables them to function as a nonhalogenated flame-resistant and thermal insulation filler. Their spherical structure, moreover, as compared to irregularly shaped fillers, allows for optimally dense packing.

Their average particle size is approximately 51 µm, and their carbon content accounts for more than 99.8 % of the total composition. This is a result of the production process of those microspheres, where hollow phenolic resin beads are used as raw materials, undergoing carbonisation followed by graphitisation at an extreme temperature of 2000ºC (3632ºF).

The table below shows the important material properties of SIGRATHERM® graphitised microballoons with their relative values at room temperature.

Table 1. Material properties of SIGRATHERM® graphitised microballoons.

|

Material properties |

Typical values (at 20ºC) |

|

General |

|

|

Carbon content |

99.8 % |

|

Ash content |

0.2 % |

|

Moisture content |

0.1 % |

|

Tap density |

0.18 g/cm3 |

|

True particle density |

1.43 g/cm3 |

|

Sodium content |

25 ppm |

|

Sinkers |

15 % |

|

BET |

1.25 m2/g |

|

Dimension |

|

|

D50 |

51 µm |

|

Particle size < 50 mesh/300 µm |

98 % |

Applications and suppliers

Industries that have been calling for lightweight, durable and dimensionally stable composite materials to meet their application demands go beyond aerospace to involve construction, defence, maritime, and the rubber & plastic industries.

All these industries could make very good use of microballoon-integrated materials, as they provide evident product enrichments and process enhancements. Some of the common resulting composites of the versatile SIGRATHERM® microballoons include, among others, acrylonitrile-butadiene-styrene (ABS) composites, epoxy composites, phenolic resin composites and syntactic polymer foams.

SGL Carbon continues to lead in providing carbon-based solutions, especially with its high-quality materials and products that consist of specialty graphite and composites.

Visit the SGL Carbon’s supplier page for more information on their materials listed on Matmatch and to get in direct contact with them.

Figure 2. SIGRATHERM® graphitised microballoons. Courtesy of SGL Carbon

Artikel von <a href=/suppliers/sglx-sgl-carbon> SGL Carbon </a>SGL Carbon

SGL Carbon is a technology-based company and world leader in the development and production of carbon-based solutions. Its high-quality materials and products made from specialty graphite and composites are used in industrial sectors that determine the future: automotive, aerospace, solar and wind energy, semiconductor and LEDs as well as in the production of lithium-ion batteries, fuel cell and other energy storage systems. In addition, SGL Carbon develops solutions for chemical and industrial applications.

Materials, products and solutions from SGL Carbon are embedded in the major topics of the future: sustainable mobility, new energies and cross-industry digitization. Further developments in these areas demand more intelligent, more efficient, networked and sustainable solutions. This is where the entrepreneurial vision of SGL Carbon evolves around: contributing to a smarter world.