What is Nylatron® GS?

The Nylatron® family of engineering thermoplastics is a trade name from DSM Plastics and refers to extruded nylon filled with molybdenum disulphide (MoS2). Nylatron® GS in particular is composed of MoS2 filled nylon 66 (PA66). The MoS2 is present as finely divided particles that are evenly dispersed during the polymerisation process. This results in a high strength and toughness material with greatly enhanced bearing properties.

Here, you will learn about:

- What nylon is

- The Nylatron® series

- Features and properties of Nylatron® GS

- Applications of Nylatron® GS

Nylon and the Nylatron® family

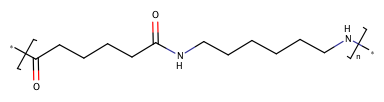

The Nylatron series belongs to the nylon family. Nylon is the generic name refering to repeating units of polyamides (PA), and are synthetic polymers. Nylatron® GS in particular is made from nylon 66, of which a monomeric unit can be seen in the figure below. The number '66' in the name refers to the fact that nylon 66 itself is composed of two monomers with 6 carbon atoms each. It is formed from a condensation reaction between equimolar amounts of hexamethylenediamine and adiptic acid.

Fig 1. Monomeric unit of nylon 66.

Another close member of the Nylatron family is Nylatron® GSM, which is composed of MoS2 filled with nylon 6.

Features and properties of Nylatron® GS

|

Key features and properties of Nylatron® GS |

|

High mechanical strength, stiffness, hardness, and toughness |

|

High mechanical damping ability |

|

Improved load bearing properties |

|

Lubrication properties |

|

Outstanding wear resistance |

|

Good electrical insulating properties |

In addition to improving the sliding wear of nylon 66 by increasing the lubricating properties, the MoS2 filler also improves the mechanical and thermal properties of nylon without affecting its chemical and electrical properties. In particular, the stiffness, hardness, toughness, and stability is enhanced.

Applications of Nylatron® GS

The self-lubricating properties due to MoS2 particles make Nylatron® GS well-suited for use in environments where maintenance, reapplication, and possible contamination of moving parts requiring lubrication is difficult. These moving parts made of Nylatron are able to operate requiring little to no lubrication, thus extending the service life of these materials and outlasting any conventional material replacement. These properties, combined with its high strength and rigidity, make Nylatron® GS ideal for applications in bearings, rollers, wheels, and gears. Due to its lower coefficient of thermal expansion compared to Nylon 101, these parts also have a better fit and reduced chances of seizing as bearings. These exceptional properties allow Nylatron parts to be used in such heavy loads such as bearings in industrial steel mills.

Sources

[1] Stan, F., & Fetecau, C. (2012). Characterization of viscoelastic properties of molybdenum disulphide filled polyamide by indentation. Mechanics of Time-Dependent Materials, 17(2), 205–221. doi:10.1007/s11043-012-9198-5

[2] https://www.sciencedirect.com/science/article/abs/pii/0043164891903504?via%3Dihub

[3] https://www.controlledfluidics.com/plastic-materials/nylatron-g