What is Radel® R-5100?

The Radel® R-5100 is a registered trademark of the Solvay specialty polymers division. This engineering resin is a general purpose injection moulding grade belonging to the polyphenylsulfone (PPSU) series of the sulfone polymer family. This series stands out as the highest performance of other sulfone polymers, offering good resistance to hydrolysis, high heat deflection temperature, and enhanced impact resistance and outstanding chemical resistance. These thermoplastics are inherently flame retardant.

Here, you will learn about:

- What sulfone polymers are

- Key features and properties of Radel® R-5100

- How Radel® R-5100 is processed

- Applications of Radel® R-5100

The chemistry and properties of Radel® R-5100

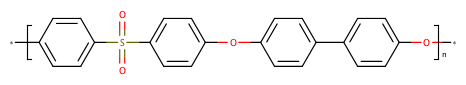

Fig 1. Monomeric unit of Radel® PPSU

The Radel® R-5100 is an amorphous thermoplastic with no distinct melting point and lacks crystallinity. Polysulfone polymers contain linked phenyl groups joined by sulfone (-SO2-) groups. The sulfone functional group provides inherent hydrolytic stability, as the hexavalent sulfur atom is in its highest oxidation state. Additionally, the sulfone functional group is surrounded on each side by a phenyl substituent, and the resulting diaryl sulfone further increases the inherent hydrolytic stability of the sulfone group.

In Radel® PPSU, the biphenyl moiety confers additional stability and extends the aromaticity throughout. This directly translates into a significantly increased impact strength value (notched Izod greater than 690 J/m) that is significantly higher than other sulfone polymers. On each side of the biphenyl is an oxygen atom that results in a phenolic ether moiety, adding flexibility to the polymer chain with the resulting properties of higher toughness, elongation, and ductility.

|

Key features and properties of Radel® R-5100 |

|

Exceptional hydrolytic stability |

|

Superior toughness |

|

High deflection temperature |

|

Resistance to environmental stress cracking |

|

Flame retardant |

|

Excellent thermal stability |

|

Good electrical properties |

Similar grades to Radel® R-5100 and colourability

Naturally opaque, the R-5100 may be easily coloured and is available in a variety of hues including:

|

Colour |

Designation |

|

|

Black |

Radel® R-5100 BK937 | |

| Bone |

|

Radel® R-5100 NT15 |

|

Grey |

|

Radel® R-5100 GY1137 |

|

Grey |

|

Radel® R-5100 GY1037 |

|

Grey |

|

Radel® R-5100 GY874 |

|

Red |

|

Radel® R-5100 RD1018 |

|

Orange |

Radel® R-5100 OR1145 |

|

|

Yellow |

|

Radel® R-5100 YL1337 |

|

Green |

|

Radel® R-5100 GN1007 |

|

Blue |

|

Radel® R-5100 BU1027 |

|

Violet |

|

Radel® R-5100 VT2582 |

|

Brown |

|

Radel® R-5100 RD1018 |

The similar general purpose grade for injection moulding R-5000 is transparent. Additional grades in the series include a transparent grade R-5500 for extrusion, higher flow transparent grades R-5800 and R-5900 for injection moulding, and a 30% glass fibre-reinforced grade RG-5030.

Applications

Radel® R-5100 is developed for injection moulding purposes.

Due to its high thermal stability, the Radel® R-5100 finds applications in medical equipment such as sterilisation cases and trays, as well as dental and surgical instruments. Its high hydrolytic stability also allows for it to be steam sterilised for over 1000 cycles without significantly losing its functional properties. It has also been cleared for safety for use in the human body and can be used as implantable devices. Its high chemical resistance notably includes chlorine, which is present in many disinfectants and detergents.