Weld Spatter and How Anti-Spatter Materials Can Minimise it

AMPCO METAL

No matter how immaculate you would like your welding process to be, you are almost always faced with the issue of beads of molten metal spurting all over your work and even your body. These are called weld spatter, and they come in liquid form, sticking to almost any place they fall upon. In general, weld spatter is the biggest enemy in any welding environment, as it results in a messy welding area, damage to the body resting units, and prolonged downtime for cleaning and maintenance. In order to overcome this problem and obviate weld spatter, one of the key solutions is material selection. The quality of your welded material defines the amount of spatter you will encounter. What anti-spatter materials are best for welding, and how are they used?

Weld spatter, typically, is a welding defect and a nuisance for welders. Despite the fascination of watching sparks, its impact is usually detrimental to the project. Once the spatter lands on a surface, it is an unwanted waste material that needs cleaning, which in many cases, is excessive. That means, welders would have to halt their welding process to clean their work, which results in extended downtime.

Furthermore, often these molten blobs land on the part resting units, damaging their surfaces. Such an issue would require maintenance or replacement of these units, which adds undesirable costs to the project budget. Not to mention the safety concerns if the safety equipment is not used properly, as such blobs could cause severe skin burns.

So, in order to avoid or minimise this issue, we need to understand the causes of weld spatter and how it takes place.

What causes weld spatter?

During welding, especially MIG welding (Metal Inert Gas Welding), the main causes of spattering are the following:

- Metal composition and coating

- Metal’s cleanliness (dirty metal)

- Welding filler grade and cleanliness (contaminated filler)

- Welding gas, technique, and settings

Metal composition and coating

The composition of your part’s material is a crucial aspect of your welding process. Whether it’s the level of weldability of its elements or the presence of undesirable additives in its composition, the metal you are welding should be selected with the right welding properties in mind.

In several cases, the metal is coated with other coating material to protect the metal against corrosion, such as a galvanized coating. The best solution is to grind off the coating material prior to welding to ensure a pure welding surface, which would reduce spatter.

Metal’s cleanliness

Similarly to the unwanted additives in the composition of the metal, residual substances on the metal’s surface are disadvantageous and would result in more weld spatter. Such substances, like dust, grease, oil, or marker lines, result in a dirty metal piece. It is important to clean the part well before welding.

Welding filler grade and cleanliness

As the quality of your metal, the quality of the filler material can affect your welding process and may cause extra spatter if it is a low-grade filler. Besides, if the filler gets dirtied (with dust, dirt, or oil) or begins to corrode, such a contaminated material would add to the spatter when entering the weld.

Welding gas, technique, and settings

The gas used in welding can highly impact the cleanliness of the weld. Whether it is carbon dioxide, argon, or any other gas, it is important to select a gas that is suitable for the material being welded, as a low-quality combination would cause bad spattering.

The welding technique indicates the speed and the angle at which a welder works. The steeper the angle and faster the drag, the more spatter is produced. Finding the optimal angle (~ 15°) and travel speed ensures a cleaner weld and less spatter.

Furthermore, the settings of the welder you are using could be a cause of weld spatter. If the voltage, wire speed, and the amperage are not well configured – i.e. higher voltage, lower wire speed, and higher amperage – there is a high risk of spatter.

So, taking all these causes into consideration, what is the best way to get rid of weld spatter?

The best solution to prevent weld spatter: anti-spatter materials

Usually, in order to shield the parts from weld spatter, the welding and maintenance personnel resort to applying additional coating on the units or utilizing spatter protection sprays and gels at regular intervals. While such a solution would protect against spatter, it does not sufficiently prevent it.

The material selection remains the most effective aspect that engineers can utilize to minimize spatter and maintain a high-quality weld. AMPCO METAL, an integrated metal producer that provides premium metal alloys, has built new anti-spatter materials under the names of AMPCOLOY® Mylar, AMPCO® Mylar, and AMPCOLOY® Nozcap, which enable engineers and welders to alleviate the issue of weld spatter.

AMPCOLOY® Mylar and AMPCO® Mylar

Such materials exhibit anti-spatter properties and are used on MIG / MAG welding fixtures as Mylars, resting blocks, clamping blocks, locators, and pressure pads. With minimal sticking/deposition occurrences, the spatter on them is easily cleanable. In addition to that, AMPCOLOY® and AMPCO® materials are easily machinable and have proven to result in the extended life of the welding process units due to their high hardness and high wear resistance. Table 1 below shows the difference between ordinary resting blocks mode of low carbon steel and AMPCOLOY® Mylar. Notice the evident advantage that AMPCOLOY® materials provide.

Table 1. Difference in welding properties between ordinary resting blocks made of low carbon steel and AMPCOLOY® Mylar

|

Ordinary resting blocks made of low carbon steel, heat-treated and blackodised |

Resting block made in AMPCOLOY® Mylar |

|

No resistance to weld spatters |

Very high resistance to weld spatters |

|

Mylar gets damaged if placed near to the welding area |

Can be placed very near to the welding area |

|

Additional heat treatment and coating is required |

No need for additional heat treatment or coating |

|

Anti-spatter gel or spray needs to be applied at regular intervals |

No need for anti-spatter gel or spray |

|

Heavy chiselling is required to clean |

Very easy to clean |

|

High downtime for cleaning and maintenance |

Zero downtime for cleaning and maintenance |

|

Very low life of the mylar |

Extended life of the mylar |

|

Creates a problem for resting, clamping, and assembly of the component |

Perfect resting, clamping, and assembly of the component due to undamaged mylar |

The materials that AMPCO METAL supplies for these solutions include AMPCOLOY®940, AMPCO®18, AMPCO®21, and AMPCO®25. These alloys have exceptional wear and fatigue resistance with good ductility and unusual toughness.

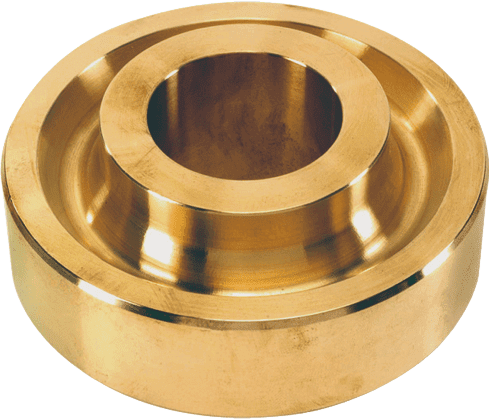

AMPCOLOY®940, in particular, is a beryllium-free copper alloy that has a high hardness level and various dimensional capabilities. It is a primary alloy for clamping blocks and works efficiently as mylars that are in close proximity from the welding area. AMPCO®18 is used for resting blocks and clamping blocks, while AMPCO®21 is mostly used for locators due to its higher hardness and wear resistance under axial loading. AMPCO®25 is used primarily in pressure pads owing to its high hardness and excellent compressive strength.

AMPCOLOY® Nozcap

AMPCO METAL also produces materials for welding nozzles. A MIG welding nozzle, for example, can remain free from spatter building up on its surface when made from AMPCOLOY® Nozcap. This, evidently, extends the nozzle’s service life significantly.

As compared to conventional nickel-chrome-plated copper nozzles, MIG welding nozzles made from AMPCOLOY® Nozcap are highly resistant to weld spatters, do not require any additional plating or anti-spatter sprays, and do not suffer from excessive turbulence in the shielding gas flow thanks to the absence of spatter build-up. This improves the weld quality, minimizes cleaning time by 99%, and avoids the need for downtime, resulting in an increase of 40% in throughput.

Selecting the right material from the right supplier

In order to attain and maintain high-quality welds while preserving their equipment, engineers and product developers have to find the right materials. For that, material suppliers have to provide top-notch materials with suitable properties that can help their customers in their material selection. AMPCO METAL, an established metal producer for 100+ years of service, produces metals in various shapes and forms, such as round bars, plates, tubes, and rectangles. The company is present in multiple countries in Europe, USA, Asia, and South America. To support engineers with their material selection, AMPCO METAL has listed their materials here on Matmatch, with their properties and application data.

Visit the AMPCO METAL supplier page for more information on their materials and to get in direct contact with them.

Fotogalerie

Artikel von <a href=/suppliers/ampc-ampco-metal> AMPCO METAL </a>AMPCO METAL

AMPCO METAL, headquartered in Switzerland, is a leading international manufacturer and integrated distributor of specialty copper alloys and engineered products.

The company was founded in 1914 in the USA, as an innovator in the introduction and application of aluminium bronze alloys.

It has also introduced to the market several new metallurgical and process techniques that have made AMPCO METAL the recognized quality leader in specialty bronzes and copper alloys.

Over the years, AMPCO METAL has served customers throughout the world in a variety of applications seeking wear, corrosion-resistant and high conductive properties.

Major industries served include: chemical and petroleum, machine tool, primary metal producers, transportation and a wide range of industrial and commercial machinery.

To obtain unique and consistent alloy characteristics, AMPCO METAL utilizes some of the most advanced equipments in the industry, a highly skilled engineering staff and sophisticated quality control procedures.

This allows AMPCO METAL to offer superior lot-to-lot consistency for predictable results.Conscious of the environment, AMPCO METAL utilizes advanced technology throughout its plants and service centers to rigidly maintain clean air and water programs.

AMPCO METAL manufactures a wide range of alloys in a variety of grades and conditions and distributes them through its worldwide network of service centers. This enables AMPCO METAL to work closely with its customers to produce specialty alloys with the properties and characteristics they need.

A century of engineered excellence

Since 1914, AMPCO METAL has worked with industry partners across the Aerospace, Automotive, Steel & Titanium industries, as well as Marine, Oil, Gas & Chemical, along with and a host of others., across a range of applications, including friction & wear, corrosion resistance and heat & electrical conductivity. This unparalleled experience, combined with our technical expertise and engineered alloy excellence mean we’re able to be a global partner in creating metal solutions for our customers.

Superior Casting

Introducing MICROCAST®, our patented high-performance aluminium bronze and specialty copper alloy production technology that delivers the most uniform grain size with the most outstanding wear resistance.

AMPCO®Aluminium Bronze

- A highly polishable, high-strength and better alternative to brass with better grain.

- Higher mechanical properties without lead and cleaner trace elements.

- High wear characteristics and corrosion resistance.

- Best movement material for sliding, motion and typical wear parts with friction problems.

- Recommended for how to solve cavitation problems, galling, tooth flank damage, avoiding nickel contamination and surface problems on stainless steel.

Aluminium bronzes are part of a copper alloys family containing aluminum as their principal alloying element. The properties of these alloys are governed by the properties of copper and aluminium when melted and casted together in rigorous and well-controlled processes.

Aluminium is soluble in copper up to about 8 wt%. This solution is characterized by a homogeneous single alpha phase which displays high ductility and excellent corrosion resistance by forming a protective skin of aluminum oxide on the surface. When increasing the aluminium content, a second phase forms in the microstructure known as the beta phase. These alloys are harder than a single alpha phase, with higher strength and higher mechanical properties.

Other alloying elements can be used like nickel to further improve the resistance to corrosion and mechanical properties. These alloys are used in highly-loaded construction parts that can be exposed to aggressive corrosion environments.

AMPCO METAL was a pioneer in developing aluminium bronze alloys and continues to engineer premium products for critical applications with its well-known AMPCO® product line to this day. Our high-quality, high property and uniquely hard metal range is trusted the world over for its broad use. AMPCO® Aluminium Bronze even extends to food-approved applications through alloys such as AMPCO® 8, AMPCO® 18 and AMPCO® M4.

AMPCOLOY®High Copper Alloy

- A polished hard version copper alloy without coating or lead and clean trace elements

- Best material for injection moulding and welding, with the highest thermal conductivity for mould problems.

- An alternative to Wolfram cathodes for cathode welding material.

- Increases productivity of plastic injection while decreasing their cycle times.

- Also used when food approval is required.

AMPCOLOY® High Copper alloys are engineered with exceptional conductivity, high strength and unique wear characteristics, delivering higher lifetime, quality and performance, with cleaner trace elements. Copper has a face-centered cubic lattice, allowing it to have good cold working properties in addition to high electrical and thermal conductivity. With the addition of carefully selected alloying elements in well-defined proportion, high copper alloys develop the necessary strength and hardness properties with little decrease in electrical conductivity. These material are used in critical applications where both conductivity and mechanical properties are required.

With over a century of expertise, AMPCO METAL and its AMPCOLOY® product line are synonymous with premium quality for critical applications.

AMS Alloys

- Technically specific AMS bronze is used for parts and landing gear.

- Sometimes referred to as aerospace bronze.

AMS alloys are the results of carefully selected alloying elements, well-documented manufacturing processes and specific heat treatment parameters, achieving quality and performances that critical applications like the aerospace industry require.

Standard Alloys

- Offers high flexibility in value, size, and shape.

Standard Alloys continue the AMPCO tradition of excellence in engineered alloys, offering a premium product that can offer performance for demanding applications.

Other Alloys

- Often considered as an alternative to aluminum bronze.

Our high-strength, durable AMPCO® Alloy range and bearing material, recognized for its unparalleled ability to perform under temperature. It’s created through a patented manufacturing process that gives it greater corrosion-resistant properties for a number of specific applications.