Stainless steel with ideal magnetic properties

Ugitech

Ugitech expands its portfolio

From liquid metal to tested magnetic rod – Ugitech offers an extensive portfolio of stainless steel with ferromagnetic properties. The Swiss Steel Group company has many years of experience in steel production. Customers receive technical support when selecting materials and benefit from solutions that are individually adapted to the respective requirements. The ferritic and martensitic steels impress thanks to top quality and are continuously tested and proven in numerous certified processes.

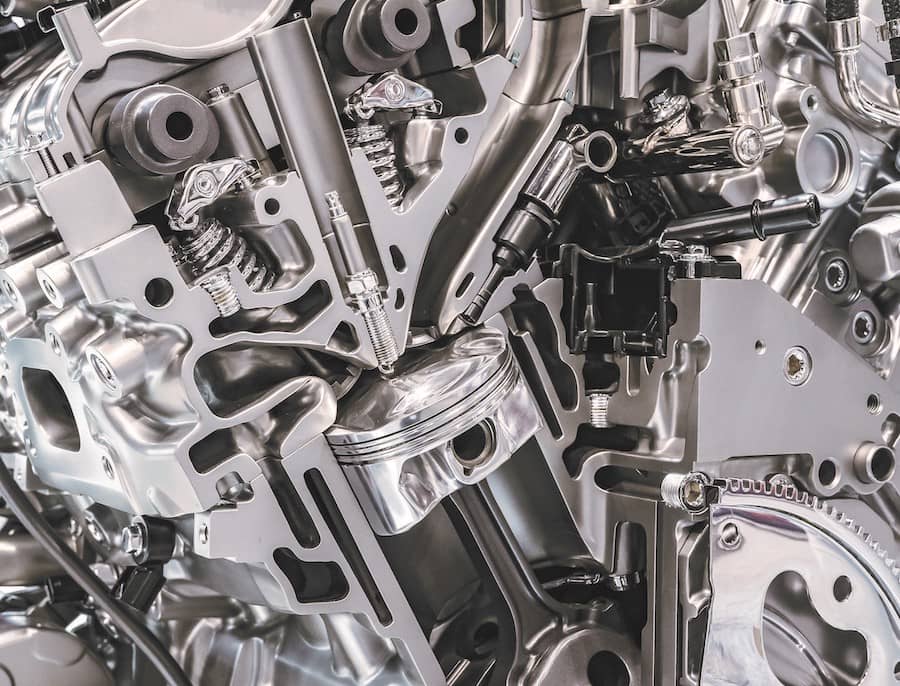

Ferromagnetic material is often used in the automotive industry, food industry, electricity sector and industrial processes. For example, the role and functioning of solenoid valves, electric pumps, injectors, disconnectors and electromagnets is based on the magnetisability of the steel used. Depending on the application, materials with high corrosion resistance, great mechanical strength or special magnetic properties are required. In addition, other characteristics such as electrical resistance and machinability as well as weldability are important. In order to be able to offer the perfect stainless steel for a wide range of applications, Ugitech has a large steel range. The customer selects the appropriate material from a variety of products with different chemical compositions and different mechanical and magnetic properties. During this process, the specialist manufacturer offers comprehensive advice and uses its years of experience as well as the latest findings from its own research and development centre to provide technical support.

A wide range of ferritic and martensitic steels

The ferritic materials developed by Ugitech are particularly suitable for electromagnetic actuators thanks to their soft magnetic properties. They differ in terms of their relative magnetic permeability and resistance to pitting corrosion. For example, the sulphurised steel grade UGI 4106 when non-magnetically annealed or IMRE when magnetically annealed exhibits a better corrosion resistance than the classical grade UGI 4105SI used in many applications. Staying in the family of sulphurised steel grades, when magnetic permeability of the reference grade UGI 4105SI is not high enough, Ugitech recommend to use UGIPERM 12FM which allows to enhance relative magnetic permeability for electromagnetic actuators from µr = 1600 to µr = 1800.

Ugitech’s steel grades are ideally suited for use in both sensors and actuators. The ferromagnetic material is available as a round bar, hexagonal steel or profile bar with different dimensions and can be processed by Ugitech if required, for example, ground or drawn.

Top-quality materials – guaranteed certified

Ugitech continuously tests the steel grades using standardised measuring instruments in certified procedures. For example, type A direct current permeameters and coercimeters are used to determine the magnetic behaviour of materials under static and dynamic conditions. The tests also include chemical analyses, metallographic examinations and non-destructive material tests. In this way, the specialist for long products made of stainless steel ensures that it fulfils customer requirements in the optimum way for the long term.

About Ugitech S. A.

Ugitech, a company of the Swiss Steel Group, is one of the leading manufacturers of stainless steel long products worldwide. The company's main products include billets, bar stock, wire rod, and drawn wire that the company produces in its own steel mill and in its rolling mills and wire-drawing plants. The stainless steels are known for their excellent mechanical properties. They are used to manufacture a wide range of parts, such as e.g. valves, turbine components, welding wire or surgical instruments. With over 100 years of experience in steel production and ongoing metallurgical research, the company guarantees optimum steel solutions for demanding applications for its customers in the automotive, construction, process and aviation industries and medical technology.

About Swiss Steel Group

The Swiss Steel Group is one of the world's leading providers of individual solutions in the special long steel products sector. The Group is one of the leading manufacturers of tool steel and non-corrosive long steel on the global market and one of the two largest companies in Europe for alloyed and high-alloyed quality and engineering steels. With more than 10 000 employees and its own production and distribution companies in more than 30 countries on 5 continents, the company guarantees global support and supply for its customers and offers them a complete portfolio of production and sales & services around the world. Customers benefit from the company's technological expertise, consistently high product quality around the world as well as detailed knowledge of local markets.

Corporate contact

Frédérique Tissot • Ugitech S. A.

Phone: +33 47989-3012 • Fax: +33 47989-3737

email: frederique.tissot@ugitech.com • Internet: www.ugitech.com

Dr. Andrea Geile • Swiss Steel Holding AG

Phone: +41 (0) 41 581 4121

email: a.geile@swisssteelgroup.com

Internet: www.swisssteel-group.com

Press relations agency

Marius Schenkelberg • additiv pr GmbH & Co. KG

Public relations for logistics, steel, industrial goods and IT

Herzog-Adolf-Strasse 3 • 56410 MONTABAUR • GERMANY

Phone: +49 2602 95099-25

email: ms@additiv-pr.de • Internet: www.additiv-pr.de

Article by Ugitech

Ugitech is one of the world's leading manufacturers of stainless steel long products.

The company's main products are: billets, bars, wire rod and drawn wire, which the company manufactures in its own steelworks and transforms in its hot rolling mills, finishing shops and wire drawing plants.

Stainless steels are characterized by their high mechanical properties and their corrosion resistance. They are used for the manufacture of a multitude of parts, including valves, turbine components, welding rods, automotive injectors or surgical devices.

With more than 110 years of experience in steel manufacturing and continuous research in the field of metallurgy, the company guarantees optimal steel solutions for the demanding applications of its customers from the automotive, construction, process industry as well as the aerospace, nuclear and medical sectors.

UGIMA® - Creating productivity

Easy Machining

The UGIMA® and UGIMA® HM or XL grades can:

- increase productivity by between 10% and 50%, depending on the grades*

- double tool life**

- provide performance levels that can be repeated from one batch to another

All this, by improving chip breakability and the surface finish of the parts.

With UGIMA® grades, this real achievement (performance level) is accessible to all types of machines and tools.

*with a constant tool lifetime – **after optimising cutting conditions

More than 30 UGIMA® grades are available

Technical support

Experts available throughout the world to help you. They can provide you with information and help you optimise your back-office or in-situ cutting conditions.

The UGIMA® solution and Ugitech’s technical support are unsurpassed!

UGIGRIP®… Choosing durability

Sustainable management of our heritage is an ethical and ecological necessity. It is also an economic imperative, which requires achieving the lowest possible life-cycle cost over the structure's service life.

In the most exposed parts of the structure, stainless steel reinforcing bars are the most efficient solution to ensure the durability of concrete. Stainless steel rebars are used for repairs and for new works, partially or completely replacing carbon steels, both in precast products and for the execution of cast-in-situ structures.

The UGIGRIP® range provides a guarantee of:

In addition to their excellent corrosion resistance which ensures a long service life for structures over several decades, the UGIGRIP® range provides a guarantee of:

- Higher mechanical properties than with conventional steel, which allows the use of smaller cross sections or a reduction in reinforcement (meaning weight and labour savings);

- Mechanical properties – yield strength and elongation – meeting the requirements of Eurocode 8, class M for earthquake-resistant construction;

- A selection of non-magnetic stainless steels for buildings where this property is required: hospitals, banks, airports, meteorological stations, etc.

- Mechanical properties at high temperature – tensile and creep – exceeding those of conventional steels, giving improved fire resistance;

- A very low thermal conductivity which gives this product exceptional properties for treating thermal bridges.

UGIGRIP® products can be delivered in various forms:

- Indented wire coils

- Indented bars

- Wire ties dia. 0.8 mm or 1.2 mm

Brands

Through its brands, Ugitech develops for its customers, a range of economic and successful grades.

EXHAUST®

- EXHAUST® F1

the only ferritic stainless steel equivalent to the austenitics for welding and assembly on exhaust lines. - EXHAUST® F1 Evolution : After the worldwide success of EXHAUST® F1 (430 LNb), Ugitech features a new evolution of MIG welding wire for exhaust lines: 430 LNbE.

SPRINOX®

Grades with high mechanical properties.

UGI®

The UGI® grades offer all possible options in terms of grade, diameter, end finishing, and quantity. They are available ex-works or ex-stock.

UGIALLOY®

Alloy welding wires.

UGICHROM®

UGICHROM® combines the high effi ciency of micro fissuring chromium plating with the technology of Ugitech's most advanced bars. For our customers, this guaranteed zero-defect solution is indispensable for many cutting edge applications (offshore, nuclear, wind power, aeronautics, etc.).

UGIFIL®

A wire that lasts, doesn’t stretch out of shape, and practically eliminates maintenance.

Breaking loads : UGIFIL® Over 135 kg/mm².

Elongation : UGIFIL® Less than 3 %.

UGIGRIP®

A complete range of products used for concrete rebars. These stainless steel rebars are the solution to the problems encountered today in building and construction. They guarantee safety, durability, reduced maintenance costs andimproved living conditions. UGIGRIP®

UGILEAN™

Martensitic and ferritic grades characterized by their excellent levels of mechanical or magnetic properties.

UGIMA®

Our range of improved machinability grades recognized by users. This process allows unparalleled cutting conditions and tool wear levels without affecting the intrinsic properties of the grades. We offer a growing range in a UGIMA® version.

UGIMA® HM

The generation of UGIMA® that gives an additional boost to the productivity of grades 1.4305,1.4404, and 1.4307.

UGIPERM®

The optimum magnetism/machinability compromise in stainless steel.

UGIPLEX®

An excellent compromise between corrosion resistance and the mechanical properties of the austeno-ferritic grades (Duplex).

UGIPURE®

Obtained with the ESR process, these stainless refractory products with improved cleanliness and structure respond to the strictest requirements of high-tech industries.

UGISHAPE™

Our isoscele triangles mainly dedicated to Oil & Gas filtration.

UGI® Slick

The "must-have" for Slicklines in the Oil & Gas industry.

All Slick lines are 100 % Eddy Current tested before delivery to ensure that surfaces are free of cracks, and now an additional process has been added to detect defects under the surface, which is not normally possible with EC testing.

Ugitech can offer a wide range of grades, including Austenitic Stainless Steels, Duplex and Super Duplex grades and Nickel or Cobalt based alloys.

UGIWELD™

Stainless steel welding wires.