Lavergne: A Visionary Company Advancing & Expanding Plastic Recycling

Samir Jaber

As society’s use of plastics has been on the rise, plastic waste management has become a major global concern, whether it’s ocean-bound plastics, electronic plastic waste, or plastics in landfills. Plastic recycling is more important now than ever, and its adoption has to be as widespread as possible to ensure an adequate solution for such a waste crisis. That is why Lavergne, a producer of high-quality, post-consumer recycled plastic, has set its sights on maximizing recycling opportunities by expanding operations. Lavergne aims to make high-quality recycled plastic commonly available by expanding its presence and collaborations globally.

Why recycled plastic is urgently needed

Since its inception in the early 1900s, plastic has increased dramatically in production and use to become the ubiquitous material and, unfortunately, the ubiquitous waste that we have today. In fact, plastic waste’s presence in the natural environment has become so pervasive that scientists have begun to consider it a potential geological indicator of the Anthropocene era [1].

This is supported by the increasing amount of global plastic production, reaching a whopping 359 million tons in 2018 [2], almost as much as the current total biomass of humans. Besides, at the current growth rate, plastic production is estimated to grow twofold between 2019 and 2035 and fourfold by 2050 [3]. This is followed by an increase in the corresponding embodied energy and carbon emissions, not to mention the accruing plastic waste, one of the most critical contributors to the world’s waste crisis today.

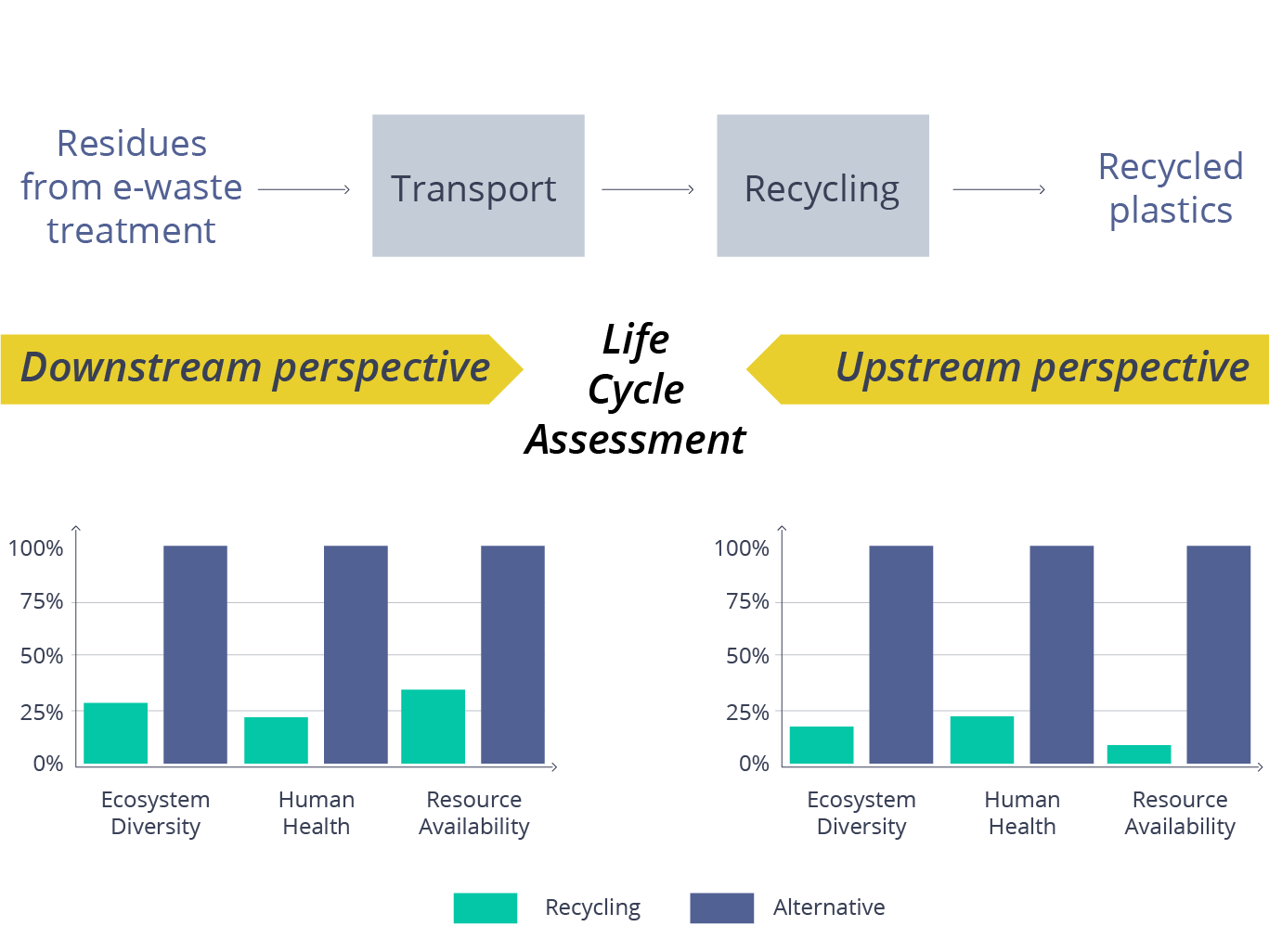

That is why the creation of recycled plastic has become a vital undertaking in order to reduce the environmental impact of plastic waste. In a study investigating the environmental benefits of recycled plastic against existing alternatives, researchers examined the environmental impact of post-consumer recycled (PCR) plastics production from waste electrical and electronic equipment (WEEE) treatment residues. They found out that the impact of PCR plastics production was four times less than that of municipal solid waste incineration (MSWI) and six to ten times less than that of the production of virgin plastics [4]. They calculated the impact score based on a life cycle impact assessment (LCIA) method called ReCiPe. This includes multiple characterization factors corresponding to human health, ecosystem quality, and resource scarcity. These characterization factors describe the environmental impact per unit stressor, such as per kg of emissions or resource used.

Figure 1. A representation of the environmental impact of recycled plastic production compared with alternatives from the upstream perspective (i.e., MSWI) and downstream perspective (i.e., virgin plastic production). (Figure reproduced from ref. 4)

However, despite the evident benefits of recycling, the amount of recycled plastics remains relatively small. In Europe (EU28+NO/CH), around 29.1 million tons of post-consumer plastic waste were collected in 2018, with only 32.5% sent to recycling and 24.9% sent to landfills – the rest accounted for by energy recovery [2]. A 2020 study on the environmental benefits of improving packaging waste collection in Europe showed that plastic’s capture rate from packaging waste could be increased by 138% by following best practices of municipalities in collection. This, alongside minimizing the losses within the resource recovery process chain, can help push towards reaching recycling targets [5]. Ideally, in order to achieve a circular plastic economy, zero waste to landfill has to be attained, and the proportion of plastic recycling has to increase significantly.

Expanding plastic recycling services

Normally, the separation and recycling of plastics take place at large, distinct, centralized factories that import all the end of life products from the region and possibly elsewhere. However, plastic is often prevalent in economically disadvantaged regions, where the infrastructure for recycling is limited and may cause serious health and environmental issues. Contamination and poor transportation of plastic waste after collection are also significant problems for regions without recycling infrastructure.

In order to meet and overcome such challenges, solid waste management and recycling are best implemented on a local level. In other words, following a decentralized approach to recycling can be vital in establishing a circular plastic economy. Yet, for this to be successful, recycling technologies have to be cost-effective, socially appropriate, and economically feasible. Additionally, the plastic must be used to produce a good quality product.

Figure 2. Stacks of plastic bottles ready for recycling.

Lavergne, a producer of high-quality post-consumer recycled plastics, envisions leading the world in a transformation from linear to circular plastics. By providing high-quality PCR resins to be used in new products, Lavergne is helping to reduce the world’s reliance on virgin plastics. Most importantly, with a mission to help businesses, committed to sustainability, transition to circular plastics, Lavergne is working on expanding availability of high-quality recycled plastics by expanding its international footprint to multiple areas around the world, currently spanning three continents. Headquartered in Montreal, Canada, its production locations are found in Canada, Vietnam, Belgium, and Haiti.

Plastic Care Center (Canada, Belgium)

This facility is where plastics, received from partner recyclers, are treated and restored rather than let go to landfills. They are shredded into smaller flakes, separated by type and color, cleaned to remove contaminants, and deep washed, and then sorted and homogenized in 16 mixing silos.

Additive Mixing Center (Canada, Belgium, Vietnam)

In this facility, in order to rebuild the molecular chain and create a resin tailored for specific client applications, Lavergne develops an additive formulation, which includes a recycled base polymer and additives. These additives, the secrete sauce, ensure that the resin meets new resin specifications including color matching.

Reactive Compounding Center (Canada, Belgium, Vietnam)

Here, the melting and blending processes of the base polymers and additives are done. The resulting compound then undergoes extrusion and is cut into pellets.

Washing Line (Haiti)

This project has helped divert ocean-bound plastics from reaching the waters and prepared them for reuse as high-quality engineering plastic. Not only has it been beneficial to the environment, but the collection project has also created economic and educational opportunities for members of the local communities.

Figure 3. Lavergne's Haiti project has helped divert plastics from the ocean, create new jobs, and help build communities. (Credit: Lavergne)

This efficient recycling process has helped Lavergne design, develop and manufacture high-value sustainable plastic resins using 100% post-consumer recycled plastics base polymers, including rPET, rABS, rHIPS, rPC, and rPP, all fit for injection molding processes. Lavergne’s commitment to sustainability and its approach to recycling have positioned it as an example of how circular plastic can be aimed for and attained. Today, Lavergne’s recycled plastic materials can be found on Matmatch with an explanation of their properties, applications, and sustainability features. Explore the variety of Lavergne’s PCR resins now.

Visit the Lavergne supplier profile for more information and to benefit from their expertise and technical support.

Article by Lavergne

Lavergne provides recycled resin that can be upcycled into new products.