Austenitic Stainless Steel: Properties, Applications and Grades

Austenitic stainless steels are the most widely used variant of stainless steel. They contain very low levels of carbon and high amounts of nickel and chromium, which are the main contributors to their formability, corrosion-resistance and wear-resistance. They are also non-magnetic in their annealed state but can become slightly magnetic when cold worked.

Austenitic stainless steels are categorised in the 200 and 300 series in the AISI/SAE grade system, which contain between 2% to 20% of nickel and between 16% to 30% of chromium.

The 300 series of austenitic stainless steels are chromium-nickel alloys, with at least 8% nickel, which is the minimum amount required to convert all the ferrite into austenite in an 18% chromium stainless steel.

The 200 series was developed in the 1940s as an economical alternative to the 300 series. It was developed to use nitrogen in addition to a lower amount of nickel at a time when nickel was much more expensive and scarce.

304 stainless steel is the most common and most widely used of the nickel-based austenitic stainless steels. The grade 304 usually consists of around 8% nickel and 18% chromium.

316 stainless steel is another commonly used grade that has an additional 2% of molybdenum which results in higher corrosion resistance.

In this article, you will learn about:

- The properties of austenitic stainless steel

- The production and processing of austenitic stainless steel

- The applications of austenitic stainless steel

- Grades & standards of austenitic stainless steel

- Future trends of austenitic stainless steel

The properties of austenitic stainless steel

Austenitic stainless steels are characterised by their face-centred cubic (FCC) crystal structure, which is attained when a sufficient quantity of austenitizing elements such as nickel, manganese, carbon and nitrogen are added to the alloy of iron and chromium.

Austenitic stainless steels can be produced to be very soft with a yield strength of about 200 MPa and they can be strengthened by cold working, which can raise the yield strength by up to a factor of ten. Unlike ferritic alloys, they can retain their ductility at cryogenic temperatures and their strength at high temperatures. Their corrosion resistance can range from regular everyday use to highly specified use such as in boiling seawater. Despite their superiority among stainless steels, austenitic steels have inferior resistance to cyclic oxidation compared to ferritic alloys and they are also susceptible to stress corrosion cracking. The endurance limit of austenitic steels is lower (~30% of their tensile strength) than ferritic steels (~50 - 60% of their tensile strength) which means they are more prone to fatigue failure [1].

Further, austenitic stainless steels, with the addition of nickel, are suitable for low temperature or cryogenic applications. Other elements such as silicon, aluminium and niobium may be added to give the steel certain properties such as resistance to halide pitting or oxidation. Sulphur or selenium can be added to certain steel grades to improve their machinability [2].

The table below presents selected properties (in an annealed state) of some common grades of austenitic stainless steels.

Table 1. Properties of selected austenitic steel grades

|

|

||||||

|

Composition |

Fe 67.5 - 75 % |

Fe 62.6 - 68.1 % |

Fe 70.7 - 78 % |

Fe 66.4 - 74.9 % |

Fe 64.8 - 74.5 % |

Fe 62 - 72 % |

|

Cr 16 - 18 % |

Cr 16.5 - 18.5 % |

Cr 16 - 18 % |

Cr 17 - 19 % |

Cr 17.5 - 20 % |

Cr 16 - 18.5 % |

|

|

Mn 5.5 - 7.5 % |

Mn 14 - 15.5 % |

Ni 6 - 8 % |

Ni 8 - 10 % |

Ni 8 - 12 % |

Ni 10 - 14 % |

|

|

Ni 3.5 - 5.5 % |

Ni 1 - 1.7 % |

S 0 - 0.03 % |

S 0.15 - 0.35 % |

S 0 - 0.03 % |

Mo 2 - 3 % |

|

|

S 0 - 0.03 % |

N 0.32 - 0.4 % |

Si 0 - 1 % |

Si 0 - 1 % |

Si 0 - 1 % |

C 0 - 0.08 % |

|

|

200 GPa at 20 °C |

220 GPa at 20 °C |

220 GPa at 20 °C |

200 GPa at 20 °C |

200 GPa at 20 °C |

200 GPa at 20 °C |

|

|

310 MPa at 20 °C |

460 MPa at 20 °C |

250 MPa at 20 °C |

240 MPa at 20 °C |

200 MPa at 20 °C |

240 MPa at 20 °C |

|

|

46 % at 20 °C |

46 % at 20 °C |

52 % at 20 °C |

52 % at 20 °C |

42 % at 20 °C |

42 % at 20 °C |

|

|

660 MPa at 20 °C |

810 MPa at 20 °C |

630 MPa at 20 °C |

600 MPa at 20 °C |

550 MPa at 20 °C |

580 MPa at 20 °C |

|

|

1.45E+7 S/m at 20 °C |

- |

- |

1.39E+7 S/m at 20 °C |

7.54E+7 S/m at 20 °C |

7.54E+7 S/m at 20 °C |

|

|

1.3E-5 1/K at 20 °C |

1.4E-5 1/K at 20 °C |

1.2E-5 1/K at 20 °C |

1.7E-5 1/K at 20 °C |

1.7E-5 1/K at 20 °C |

1.6E-5 1/K at 20 °C |

|

|

15 W/(m·K) at 20 °C |

11 - 21 W/(m·K) at 20 °C |

11 - 21 W/(m·K) at 20 °C |

16 W/(m·K) at 20 °C |

16 W/(m·K) at 20 °C |

15 W/(m·K) at 20 °C |

|

|

Melting point |

1375 - 1450 °C |

1375 - 1450 °C |

1375 - 1450 °C |

1400 °C |

1400 °C |

1380 °C |

|

500 J/(kg·K) at 20 °C |

460 J/(kg·K) at 20 °C |

450 J/(kg·K) at 20 °C |

500 J/(kg·K) at 20 °C |

500 J/(kg·K) at 20 °C |

490 J/(kg·K) at 20 °C |

The production and processing of austenitic stainless steel

The production of austenitic stainless steel is largely the same as the process for producing other types of stainless steel. The main difference lies in the ratio of the metals mixed in the melt and the heat treatment used to achieve austenite in the steel. The process for making austenitic stainless steel may be summarised as shown below.

- The raw materials (iron, chromium, nickel, etc.) are melted in an electric furnace in the specific ratio required for the desired type of austenitic stainless steel. The melt temperature typically reaches up to 1,400°C – 1,500°C and is held at that temperature for up to 12 hours.

- When the melting and mixing is completed, the molten steel is cast into forms such as blooms, billets, slabs, rods, etc. depending on the desired finished product.

- The steel then undergoes a hot rolling forming operation where the steel is heated up to 1,100 °C (above its recrystallization temperature) to make it soft and pliable and passed through rollers, which render it into steel bars, sheets, wires or plates.

- The next step is heat treatment or annealing. This is a process of precise heating and cooling to relieve internal stresses within the metal and retain a specific microstructure which has the desired properties. The temperature the steel is heated to, the time it stays at that temperature and the rate and manner of cooling are all crucial to the properties of the steel.

- After annealing, other post-production processes such as descaling, cutting and finishing can now be carried out. Descaling is required to eliminate the scales that would have built up over the stainless steel during heat treatment and it can be done either by pickling with a nitric-hydrofluoric acid bath or through electro-cleaning.

Austenitic stainless steels cannot be hardened through heat treatment (although this can be mitigated by adding elements such as titanium and copper to the steel in order to make it more applicable in high temperatures). Instead, austenitic stainless steel is usually hardened via work hardening. This is the strengthening of the metal by plastic deformation.

The applications of austenitic stainless steel

Aside from corrosion resistance, which is one of the highlight properties of austenitic stainless steels, mechanical, thermal and electrical properties are also important. The nature of the requirements placed on steels, be it in the form of maximum load, rigidity, strain, yield stress, etc. must be carefully and thoroughly studied.

Microstructural analysis of the steel must be understood with respect to its specific applications. Knowledge of fracture mechanisms, nucleation, micro and macro-crack propagation under low cycle fatigue conditions are crucial especially for high-risk systems such as nuclear applications [3].

Due to the highly customisable nature of austenitic stainless steels, it has been used for a wide range of applications, from the medical sector to the automobile industry. Below are some common grades of austenitic steel with their corresponding typical applications.

Table 2. Typical applications of austenitic stainless steels [4].

|

Austenitic stainless steel |

Application |

|

Tanks, storage vessels and pipes for corrosive liquids Mining, chemical, cryogenic, and pharmaceutical equipment Kitchen equipment and cutlery Architecture |

|

|

309 (high chrome and nickel grades) |

Furnace, kiln, and catalytic converter components |

|

310 (high chrome and nickel grades) |

|

|

316L (high molybdenum content grades) |

Chemical storage tanks, pressure vessels, and piping |

|

318 (high molybdenum content grades) |

|

|

316Ti (stabilized grades) |

Afterburners Superheaters Compensators Expansion bellows |

|

321 (stabilized grades) |

|

|

200 Series (low nickel grades) |

Dishwashers and washing machines Cutlery and cookware In-house water tanks Indoor and non-structural architecture Food and beverage equipment |

Grades and standards of austenitic stainless steel

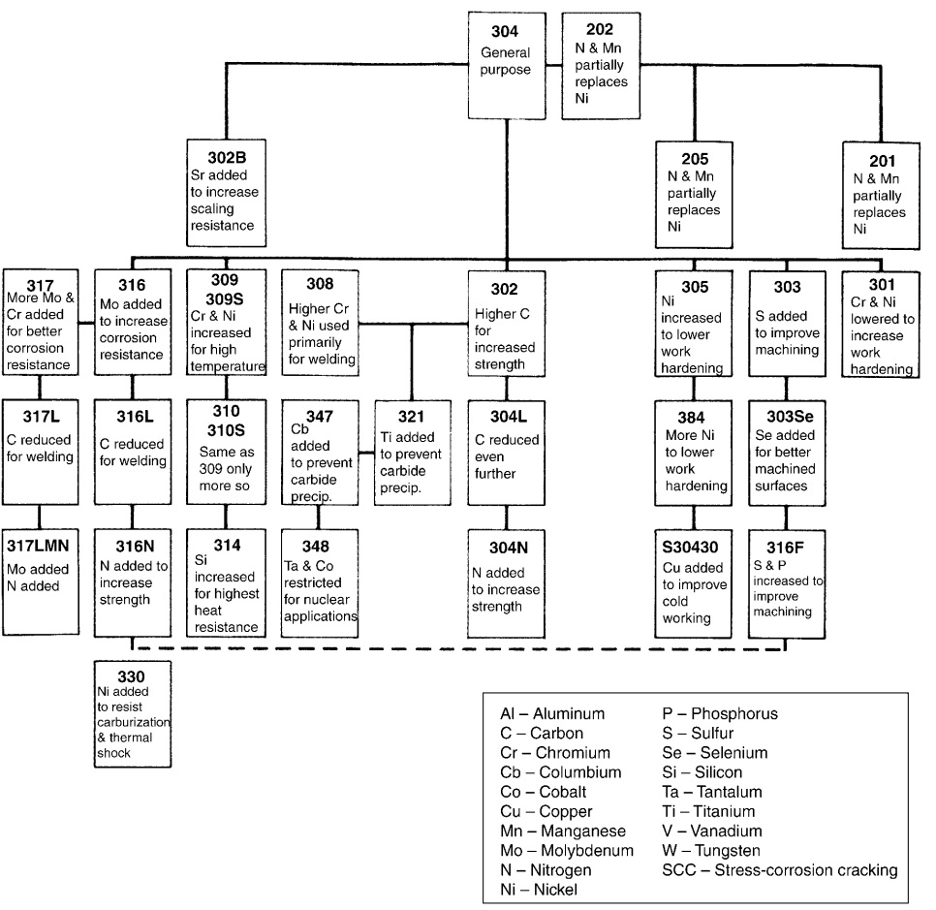

The below chart shows the various grades of austenitic stainless steels.

Figure 1. The austenitic stainless grades [1].

Future trends of austenitic stainless steel

The demand for high-temperature austenitic stainless steels is constantly growing and the market size is expected to increase at a considerable rate till 2025. Its combination of properties makes it particularly suitable for a wide range of applications in sectors such as automobile, petroleum, chemical, aerospace and energy [5].

A major part of this growth is projected to be from the automotive industry where there is a growing use of austenitic stainless steel to meet the requirements of manufacturability, weight and robustness. Typically, austenitic steel is used in the automotive industry to manufacture frames, load-bearing floor panels, reinforcements, body panels, fuel tanks, wheels, suspension arms, gear shafts and propeller shafts. The trend is expected to continue in the years leading to 2025. The surge in the use and manufacturing of electric cars in a bid to reduce carbon-based emissions also contributes to the increasing demand for austenitic stainless steel [6].

Asia is the leading consumer of austenitic stainless steels with countries such as China, South Korea and India the key players. North America is projected to have an increased market for austenitic stainless steel due to the growth of its aviation and automobile industries [6].

Quellen

[1] M. F. McGuire, “Austenitic Stainless Steels,” in Stainless Steels for Design Engineers, ASM International, 2008, pp. 69–78. [Online]. Available: https://www.asminternational.org/documents/10192/3473958/05231G_Sample.pdf/7c5e4830-b443-4c71-a8c8-1a85c5b39dc5 [Accessed May 27, 2020].

[2] S. Chaudhuri. “Heat Treatment of Stainless Steels” National Metallurgical Laboratory Jamshedpur. May 11-13, 1994 [Online]. Available: http://eprints.nmlindia.org/5764/1/H1-H12.PDF [Accessed 9 May 2020].

[3] Z. Brytan, W. Borek and T. Tański. “Introductory Chapter: Why Austenitic Stainless Steels are Continuously Interesting for Science.” Intechopen, Dec. 20, 2017 [Online]. Available: https://www.intechopen.com/books/austenitic-stainless-steels-new-aspects/introductory-chapter-why-austenitic-stainless-steels-are-continuously-interesting-for-science- [Accessed 9 May 2020].

[4] B. Terence. "The Characteristics of Austenitic Stainless Steel." ThoughtCo, Mar. 10, 2020, [Online]. Available: thoughtco.com/metal-profile-austenitic-stainless-2340126. [Accessed 9 May 2020].

[5] A. More, "High Temperature Austenitic Stainless Steel Market 2020 Global Industry Size, Share, Business Growth, Revenue, Trends, Global Market Demand Penetration and Forecast to 2025," KAKE News, April 9, 2020. [Online]. Available:, https://www.kake.com/story/41990208/high-temperature-austenitic-stainless-steel-market-2020-global-industry-size-share-business-growth-revenue-trends-global-market-demand-penetration. [Accessed May 27, 2020].

[6] A. More, "Austenitic Stainless Steel Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2019 - 2027," Transparency Market Research, 2020. [Online]. Available:, https://www.transparencymarketresearch.com/austenitic-stainless-steel-market.html [Accessed May 27, 2020]