Precious Metal Alloys and Their Use in High-Performance Applications

Heraeus

Precious metals, with their distinctive properties, have become an integrated part of our lives. Realistically, they are amongst the most valuable commodities in the world, particularly because of their rarity. Yet, they have found their way into a broad range of industries and application areas that have made many modern products possible. On top of that, alloying precious metals have also brought about new solutions, especially in industries and applications that require high performance, such as electronics, energy, and the automotive sector. So, what are those precious metal alloys? And how are they used in high-performance applications?

Figure 1. The seven precious metals and their various uses in industry. (Heraeus)

Precious metal alloys are compositions of metallic elements rarely found in nature, which possess exceptional properties that distinguish them from other metals. These elements include gold, silver, platinum, palladium, iridium, rhodium, and ruthenium. All are corrosion-resistant materials with high densities, high melting points, electrical conductivity, and excellent mechanical properties. With such unique properties, applications such as contact materials in electronics, sensors in the steel industry, glass coatings, and even satellite thrusters, all make use of precious metals.

One central aspect that influences the material properties of an alloy is its constituents’ crystalline structure. Platinum group metals (PGMs), for example, have either face-centred cubic (FCC) structure (platinum, palladium, iridium, and rhodium) or hexagonal close-packed (hcp) structure (ruthenium and osmium). FCC metals, typically, are soft when annealed and have similar workability to gold, silver, and copper. HCP metals, on the other hand, have a more complex structure that is similar to zinc, which is why adding ruthenium or osmium to platinum would significantly enhance its hardness.

PGM-based alloys and their applications

PGM-based alloys exhibit different properties, mainly based on their composition. Platinum alloys, for instance, are characterised by high melting points, good wear and corrosion resistance, and excellent mechanical properties. The most significant elements that are alloyed with platinum include rhodium, iridium, palladium, gold, and ruthenium.

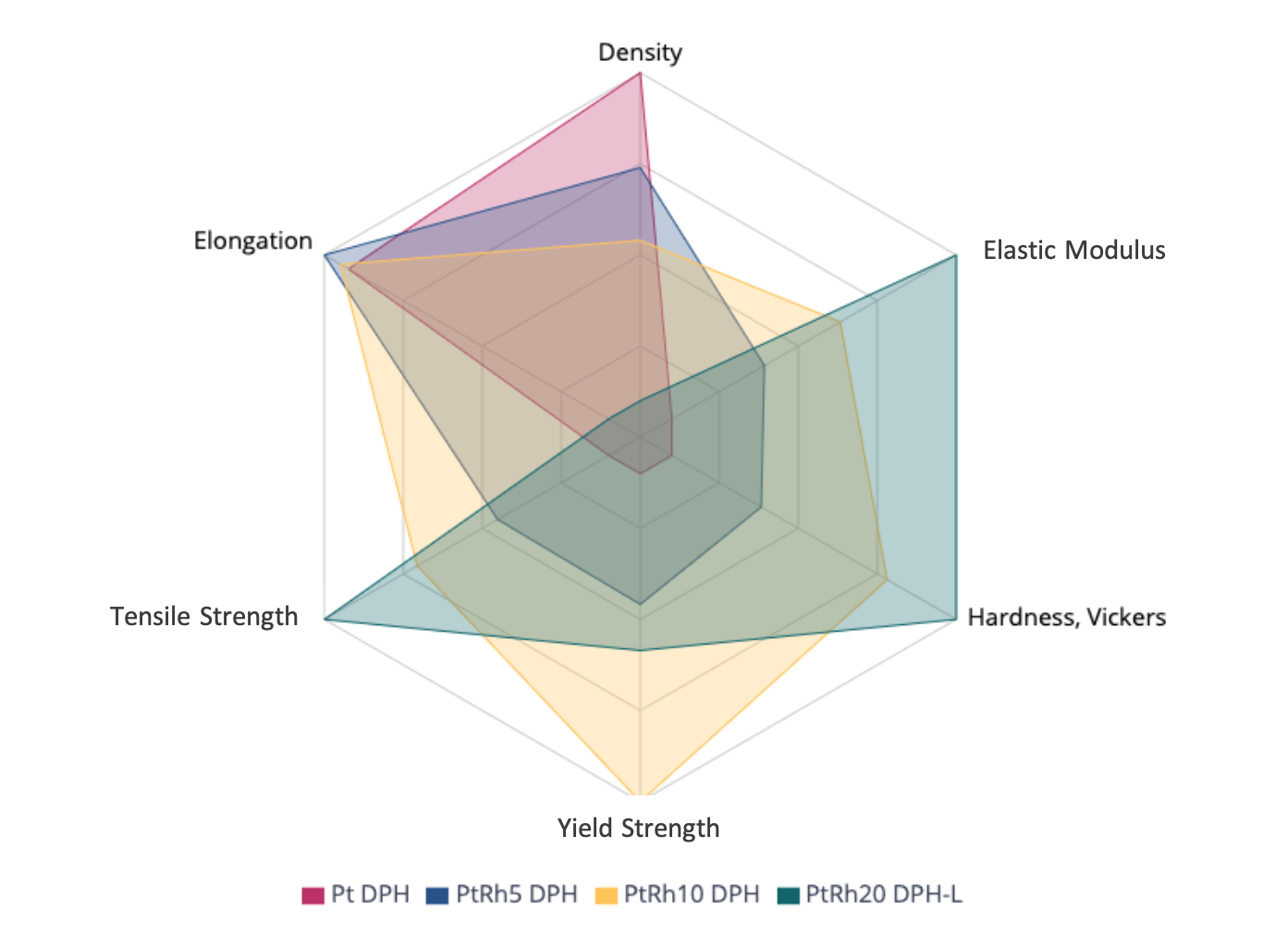

Platinum-rhodium (PtRh) alloys are ductile materials that show a consistent increase in strength and hardness with increasing rhodium content. Figure 1 shows a property comparison chart of platinum and PtRh alloys with varying compositions. Notice how increasing the rhodium content results in improved hardness, elastic modulus, and tensile strength, while density decreases.

Figure 2. Property comparison between platinum and PtRh alloys with different rhodium content. Click here to perform your own comparison scheme.

Moreover, as the percentage of rhodium increases, electrical resistivity increases rapidly, as well, until it reaches a peak with about 20% of rhodium, after which it gradually decreases to the levels of pure rhodium.

PtRh20 alloys, for example, have high strength and hardness values with excellent machinability. Increasing the rhodium content further to 30-40% improves the alloy’s strength and hardness even further while maintaining a constant elongation.

PtRh alloys are predominantly utilised in thermocouples, especially those that operate at high temperatures reaching up to 1700 ºC in both oxidising and inert environments. They also come in wire forms embedded in high-grade alumina to be used in electrical resistance windings for high-temperature furnaces (up to 1750 ºC). Other applications include crucibles in the molten glass industry and spinnerets in the fibre industry.

Platinum-iridium (PtIr) alloys, as well, exhibit improved strength and hardness as the iridium content increases. The latter complements platinum to be used in machining parts for implantable electronic medical devices. In addition to that, the jewellery industry makes use of PtIr alloys, especially those with relatively low iridium content (5-10%). Iridium can also be alloyed with rhodium to make up iridium-rhodium (IrRh) alloys, which are largely used in the automotive industry as high-performance spark plug materials and also as high-temperature thermocouples.

Another platinum alloy uses gold as an alloying element. Gold, in and by itself, is a soft metal, just like platinum. However, when alloyed together, gold can harden platinum quite effectively and increase the alloy’s strength. Yet, a rise in gold content causes a sharp decrease in elongation due to grain growth during annealing, which limits the alloy’s practical use. Most commonly, platinum-gold (PtAu) alloys are utilised in consumer electronics, tribological coatings, and electronics in extreme environments.

What about gold and silver?

Gold and silver, together with PGMs, complete the list of noble metals. They are undoubtedly the most commonly known and most widely used precious metals. Both are soft materials that can be hardened by the addition of copper.

Silver-copper (AgCu) alloys, for instance, exhibit significant improvement in hardness and mechanical stability upon increasing copper content. One example is AgCu20 by Heraeus, which has a tensile strength of 300-400 MPa. It is most commonly used in electrical contacts and cables.

Adding copper to gold also brings about improvements in mechanical properties. One common alloy has all three elements within it at varying percentages. Gold-silver-copper (AuAgCu) alloys generally have increased strength and hardness with increased copper content at the expense of their melting point. Hera 238 from Heraeus is an AuAgCu alloy that is generally used in sliding contacts, resistance wires, and slip ring brushes. It is resistant to wear and can be age-hardened easily.

Other variations of precious metal alloys involve the further additions of other PGMs such as palladium (Pd) in PdAgCu and AuPdAg alloys or palladium and platinum in PdAgCuPtAu alloys. Their uses vary based on their performances, which change according to their material properties. PdAgCu, for instance, are used in the production of probe needles.

Figure 3. High-purity granules of gold. (Heraeus)

How to find the most suitable precious metal alloys?

Despite their scarcity, precious metals continue to play major roles in our daily lives, our industries, and our market. Their excellent properties allow their use in a lot of application areas, and their ability to be alloyed with one another gives rise to new capabilities and opportunities as their mechanical properties undergo significant improvements.

Yet, in order to find and select the right materials for their applications, engineers and product developers need a reliable source that can supply them with the necessary data and materials. Here is where leading global providers like Heraeus can play a central role. With their expertise in the full precious metal loop, from trading to products to recycling, Heraeus Precious Metals (HPM) can provide high-grade materials and services. Being among the largest refiners of PGMs in the world, their materials are undoubtedly of high quality and reliability.

Visit the Heraeus supplier page for more information on their materials listed on Matmatch and to get in direct contact with them.

Artikel von <a href=/suppliers/hera-heraeus> Heraeus </a>Heraeus

A globally leading technology group, Heraeus is headquartered in Hanau, Germany. Founded in 1851, it is a family-owned portfolio company which traces its roots back to a pharmacy opened by the family in 1660. Today, Heraeus combines businesses in the environmental, energy, electronics, health, mobility and industrial applications sectors.

The Global Business Unit Heraeus Precious Metals is a leading provider of precious metal services and products. We combine all activities related to our comprehensive expertise in the precious metal loop – from trading to precious metal products to recycling.

The business line Functional Materials is an expert for mechanical processing of precious metals and their alloys. The product range varies from contact products, PGM-fabrications and semi-finished materials to high-tech materials and compounds. Their fields of application are sliding and switching contacts, spark plugs, bushings, glass tools, labware, wires and materials for probe needles as well as master alloys, TC-balls, pen points and irradiation sources.