440C Stainless Steel: Properties, Processing and Application

440C stainless steel is a member of the 400 series of stainless steels. It has the highest carbon content among them. The standout properties of this type of steel are its hardness, mechanical strength and fatigue resistance. This combination of properties makes it useful in the production of cutting tools. Due to its high carbon content, it does not have outstanding corrosion resistance, but it can still be used for applications that require moderate corrosion resistance such as surgical instruments.

440C stainless steels typically have a composition of 78 – 83.1% iron, 16 – 18% chromium, 1 – 1.2% carbon, 1% (max) silicon, 1% (max) manganese, 0.8% molybdenum, 0.04% phosphorus and 0.02% sulphur. They have a martensitic grain structure, and they are primarily hardened through solid solution strengthening with chromium and precipitation hardening of molybdenum carbides [1].

In this article, you will learn about:

- The properties of 440c stainless steel

- Heat treatment of 440c stainless steel

- The applications of 440c stainless steel

The properties of 440c stainless steel

440c stainless steel is one of four 440 stainless steel types, including 440a, 440b, and 440f. It has the highest hardness, highest strength and greatest wear resistance of all of them after it has undergone hardening via heat treatment. It is magnetic both in its pre-hardened and post-hardened states.

440c steel has moderate corrosion resistance when compared to other stainless steels, and it exhibits its best corrosion resistance in its hardened and tempered form. However, care must be taken to avoid over-tempering, which results in a decline in its corrosion resistance.

Table 1. Properties of annealed 440c stainless steel [2]

|

Property |

Value |

|

Density |

7.8 g/cm³ at 20 °C |

|

200 - 210 GPa at 20 °C |

|

|

0.27 – 0.30 |

|

|

Melting point |

1483 °C |

|

10.1 µm/m°C at 0 – 100 °C |

|

|

24.2 W/m.K at 0 – 100 °C |

|

|

460 J/kg.K at 0 – 100 °C |

|

|

600 nW.m |

|

|

13 % at 20 °C |

|

|

285 at 20 °C |

|

|

B97 |

|

|

740 - 755 MPa at 20 °C |

|

|

445 MPa at 20 °C |

Heat treatment of 440c stainless steel

440c stainless steel is martensitic, which implies that it is hardenable by heat treatment. The general goal of the heat treatment of 440c stainless steel is to limit, as much as possible, the amount of austenite in the steel and promote the creation of martensite [3]. Heat treatment of 440c steel typically proceeds as follows:

1. Full annealing

Full annealing is done at a temperature range between 850 – 900 °C, after which it is slowly cooled in the furnace to about 600 °C and then air-cooled to room temperature. Alternatively, it can be heated to between 735 – 785 °C (sub-critical annealing) and then slowly cooled in the furnace until room temperature.

2. Hardening

The steel is again heated to a temperature between 1010 – 1065 °C and then quenched in warm oil or air. Thicker sections should be quenched in oil to allow more rapid and uniform temperature drop, while thinner sections can be quenched in air.

3. Tempering

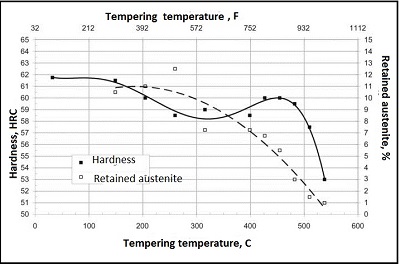

The steel is now tempered at a temperature range of 150 – 370 °C, where several levels of hardness and mechanical properties can be obtained. Tempering between 425 – 565 °C will lead to reduced corrosion and impact resistance, and tempering between 590 – 675 °C results in high impact resistance and lower hardness. The graph below shows how tempering temperature affects the amount of retained austenite and the level of hardness of 440c steel after it has been fully austenised.

Figure 1. Effect of tempering temperatures on 440c steel [4].

Newer methods of quenching 440c stainless steel down to cryogenic temperatures have shown promise due to their greater success at reducing the austenite content of the steel. Deep Cryogenic Treatment (DCT) and Shallow Cryogenic Treatment (SCT) are two methods used before the tempering process begins.

DCT involves cooling the steel from room temperature to -196 °C over a span of 3 hours, where it is held at that temperature for 24 hours and then returned to room temperature.

SCT involves holding the steel at -80 °C for 5 hours and then allowed to return to room temperature. After cryogenic quenching, the steel can then be tempered at 200 °C.

Both methods have shown increased hardness (up to 7% for DCT and 4% for SCT) of 440c steel [5].

Applications of 440c stainless steel

The unique properties of 440c stainless steels make it useful for many applications. Its excellent wear resistance makes it suitable for the production of valve components and ball bearings with industry-standard requirement Rockwell hardness of 58. Its hardness and strength also make it suitable for the production of cutting tools, such as knives and blades. It is also used to make measuring instruments like gauge blocks. 440c stainless steel is not recommended for use at high temperatures (typically higher than 400 °C) to avoid reduction of its corrosion and impact resistance.

Sources

[1] Huang, Kuo-Tsung & Chang, Shih-Hsien & Wang, Chih-Kai & Chen, J.K.. (2015). Microstructures and Mechanical Properties of 440C Stainless Steel Strengthened with TaC via Vacuum Sintering and Heat Treatments. MATERIALS TRANSACTIONS. 56. 1585-1590. 10.2320/matertrans.M2015147.

[2] https://www.pennstainless.com/resources/product-information/stainless-grades/400-series/440c-stainless-steel/

[3] Alan J. Chidester, Craig V. Darragh, Robert C. Hoff, John R. Imundo, James L. Maloney, III, Dan Nitescu, 2014. "Heat Treatment of Bearings", Heat Treating of Irons and Steels, Jon L. Dossett, George E. Totten

[4] Idayan, A., Gnanavelbabu, A., & Rajkumar, K. (2014). Influence of deep cryogenic treatment on the mechanical properties of AISI 440C bearing steel. Procedia Engineering, 97, 1683-1691.

[5] Puskar, Joseph D., Hanson, Robert A, Chidester, Alan J., & Houghton, Richard L. Effects of Varying Austenitizing Temperatures on Vacuum Hardening of Type 440C Stainless Steel. United States.