Are Technical Ceramics Sustainable Materials?

Advanced ceramics can help decarbonise our cars, power our smart cities or even boost outer space exploration.

But can they be considered sustainable materials?

This article sheds some light on the sustainability of advanced ceramics.

What are technical ceramics?

Technical ceramics were first defined by the 1993 Versailles Project on Advanced Materials and Standards (VAMAS) as highly engineered, high-performance, mostly non-metallic, inorganic ceramics with special functionalities.

Nowadays, they are also referred to as advanced ceramics, industrial ceramics, engineering ceramics, or high-tech ceramics. Regardless of the name, these solid materials are an evolution of conventional ceramics products.

Common types of advanced ceramics

Based on their chemistry, advanced ceramics are generally classified into three different groups: oxide ceramics, non-oxide ceramics and silicate ceramics.

- Explore the different oxide ceramics and their properties

- Explore the various non-oxide ceramics and their properties

Some examples of advanced ceramics belonging to these groups are alumina, silicon carbide and cordierite, respectively.

The list of advanced ceramics categories may also include perovskites and glass-ceramics.

Traditional ceramics vs advanced ceramics

Traditional ceramics have been used for centuries as material for goods storage (e.g., pottery) or construction (e.g., clay-based tiles and bricks). In comparison, the introduction of advanced ceramics is relatively recent. For instance, electroceramics and SiAlONs ceramics were introduced only in the second half of the 20th century.

While conventional ceramics are made from raw clay (≥ 20%) and other minerals (silica, sand, quartz, etc.), their advanced counterparts are obtained using either highly processed natural materials or synthetic compounds.

However, the key difference between traditional ceramics and advanced ceramics is that the latter have improved thermal, magnetic, optical, and electrical properties. For instance, zirconia, dubbed as ceramic steel, can bear temperatures of up to 2,400 ºC while preserving its strength and chemical resistance.

For this reason, high-performance ceramics can replace other materials in challenging conditions such as elevated temperature and high pressure. Also, some advanced ceramics like spinel (MgAl2O4) have nuclear properties. Being stable under radiation, these materials could be used to build fusion reactors or store radioactive waste.

How are technical ceramics made?

The manufacturing process of advanced ceramics occurs through the main steps outlined below.

- Beneficiation: The raw powder is subjected to processing to reduce its particle size and remove impurities.

- Mixing: The components of the processed powder are amalgamated to create a homogeneous blend. Binders, plasticisers and other liquid reagents may be added to facilitate the mixing.

- Forming: At this stage, the industrial ceramics mix is pressed together (consolidation) and moulded into a shape through techniques such as die pressing (for a dry blend) or slip casting (for a slurry). The formed technical ceramics are then refined via the green machining process to smooth their surface or modify their shape.

- Sintering (a.k.a. firing): Here, the “green” technical ceramics are heated at a temperature below their melting point to increase their density. Depending on the types of advanced ceramics, either solid-state or liquid-phase sintering can be applied.

How sustainable are technical ceramics?

One of the factors affecting the sustainability of advanced ceramics is their recyclability. For instance, waste alumina powder can be repurposed for making new ceramics. Researchers found that a sample with a recycled alumina content of up to 20% increased its hardness and fracture toughness.

In general, technical ceramics are inert and do not easily degrade compared to other materials like plastic. Because of this, they don’t release pollutants that could prove harmful to the environment, like microplastics.

Unlike biodegradable and compostable materials, industrial ceramic products do not convert back into their original components. On the other hand, their durability is a premium asset in terms of economic sustainability. Furthermore, technical ceramics sustain high performance over a long time, thus reducing waste disposal, maintenance costs, and further investments to make new advanced ceramics products.

Nonetheless, the manufacture of advanced ceramics has a relatively high carbon footprint. That’s primarily because of the energy-intensive production process, which involves multiple stages of thermal treatment. In fact, around 80% of the total carbon emissions take place during sintering, which also is mainly fed with fossil fuels. Yet, based on a recent analysis, the cold sintering process (CSP) could be a cheaper and greener option compared to traditional firing methods, as it can be operated at much lower temperatures ranging between room temperature and 200 ºC. However, CSP is still in its infancy and will take time to scale up as more techno-economic understanding is required.

Sustainable Applications

There has been significant research on advanced ceramics to improve their sustainability.

Scientists are developing circular methods for reusing residues from ceramic manufacturing processes. For example, a study showed how recycled crushed ceramic rubble (RCCR) could be used to improve the geotechnical properties of soil.

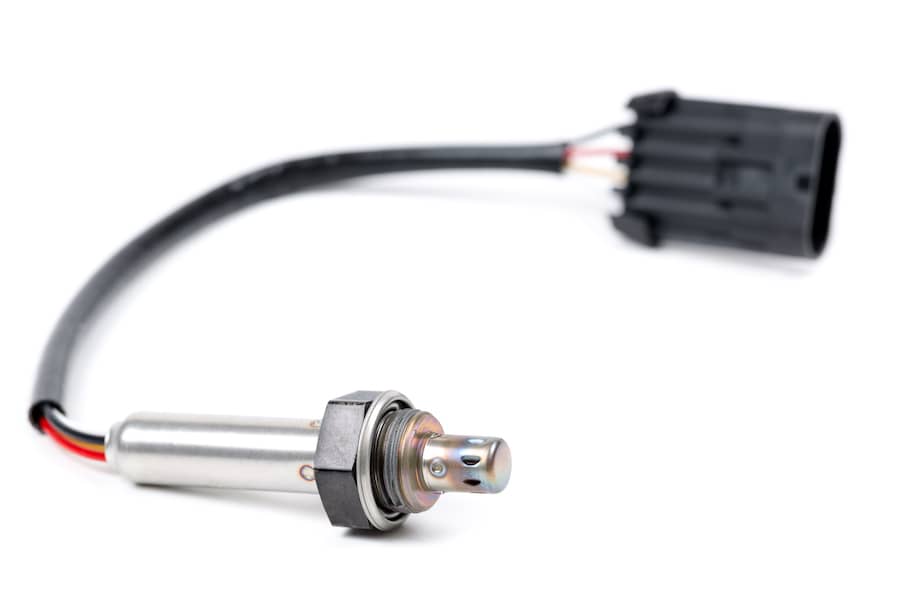

Furthermore, technical ceramics are playing a key part in the decarbonisation of the transport sector. Combining temperature resistance with electrical insulation, advanced ceramics like titanium dioxide or zirconia allow lambda sensors to measure oxygen levels in cars’ exhaust gas accurately. The sensor communicates with the car’s electronic control unit (ECU), which adjusts the air-fuel ratio of the exhaust gas based on the oxygen concentration. As a result, the engine performs better and emits fewer pollutants.

Working with a variety of fuels (e.g. hydrogen, biogas), zirconia-based solid oxide fuel cells (SOFCs) can power electric cars, which are a greener alternative to petrol and diesel vehicles. Technical ceramics such as Cordierite or Silicon Carbide are essential components of Diesel Particulate Filters (DPFs), which decontaminate cars’ exhaust emissions.

Besides the automotive industry, technical ceramics are boosting the transition to clean energy. Electroceramic coatings have been used for some time to protect wind turbines from corrosion, thus extending their lifetime. Perovskite is also a very promising material for developing high-efficiency solar panels. In June 2021, a Chinese manufacturer claimed they built a perovskite solar cell that would reach an efficiency of about 30% within a year.

According to a recent review, advanced ceramics could be the future materials for energy conversion and storage. For instance, a zinc oxide-based ceramic material was found to convert industrial waste heat into electricity. By harvesting mechanical energy from vibrations or loads, piezoelectrics can convert it into electricity.

These smart ceramic materials could then power IoT-enabled sensors, electronic devices, smart clothes, or even store power in remote locations. Thanks to their high heat capacity, ceramic fillers can store thermal energy. Not to mention that ceramics electrolytes could be a safer and more efficient solution for rechargeable lithium-ion batteries.

Space applications

The applications of technical ceramics in the space exploration programme could have an indirect impact on sustainability. Rare-earth metals (REM) and other minerals on Earth are not going to last forever. Luckily, these could be mined from the Lunar surface and near-Earth asteroids (NEAs). However, space mining still requires better equipment. That’s where advanced ceramics come into play.

Nextel, an ultra-strong fire-proof silica-based fabric, can resist the impact of meteoroids and is therefore handy to protect NASA's Space Shuttles. Also, advanced structural ceramics and carbon/ceramic composites may accelerate the progress in aerospace propulsion. But the future of propulsion is electric, especially for long-duration missions. Even in this case, advanced ceramics technology is strategic. Materials such as alumina or silicon carbide can be used to build thrusters. More cost-effective spacecraft would propel the frequency of missions and speed up the hunting of precious metals from outer space.

Conclusions

The energy-intensive advanced ceramics manufacturing is still a major challenge for the sustainability of these materials. However, the versatile and unique properties of technical ceramics combined with their long-term high performance make them a sustainable solution for the future of several industries.

If you've enjoyed reading this article, you can also read more related content here: