What is the Coefficient of Friction?

Friction is the force that opposes the movement of a solid body or fluid layer over another. One of humankind's earliest discoveries was the use of frictional heating to start fires. Another of humankind’s greatest inventions is the wheel, which takes advantage of static friction. The term friction is derived from the Latin verb ‘fricare’ meaning ‘to rub’ [1].

Friction plays an important role in numerous industrial processes relating to how an object begins to move, changes its direction, or stops. It is a major factor in the area of tribology, the study of interacting surfaces in motion. Friction is also the basis of many of our daily activities. We take advantage of it to perform tasks such as gripping objects, lighting matches, writing with pens and pencils and ironing clothes, amongst many others. [1].

In this article you will learn about:

- What the friction coefficient is

- How the coefficient of friction is measured

- Typical values of the coefficient of friction

(Tribology-abc)

What is the coefficient of friction?

Friction between two objects is usually represented by a force called the frictional force ffriction. This is proportional to the normal force N, which is the force perpendicular, or ‘normal’, to the surfaces in contact. The proportionality factor µ is known as the coefficient of friction. In other words, The coefficient of friction is the ratio of the resisting force to the motion of one body in relation to another body that it is in contact with. This can be represented simply in the following equation:

`f_{f}=\mu \cdot N`

Where

- `f_{f}` is the frictional force

- `N` is the normal force

- `\mu` is the coefficient of friction

The frictional force and normal force both are measured in Newtons, and so the coefficient of friction is a dimensionless value [2].

Typical values for the coefficient of friction generally range from 0 to 1. A value close to zero indicates that only a small force is required to cause movement of one object over the other. A value is closer to one means a large force is required.

It is generally more difficult to move one object over another starting from rest compared to an object already in motion. Put another way, the force is greater to cause an object to move. For that reason, two different coefficients of friction are generally distinguished; static and dynamic (or kinetic).

How is the coefficient of friction measured?

The measurement of the coefficient of friction is critical for many applications and industrial processes where friction characteristics must be known and controlled. Numerous techniques are used to measure friction.

Historically, the principles for friction measurement started with the methodology designed by Leonardo DaVinci in 1495. He measured friction by pulling a block tied to a cord over a surface. The friction coefficient corresponded to the ratio between the force required to move the block (the frictional force) and the weight of the block (the normal force) [3]. This method remains one of the most commonly accepted techniques. Other techniques are essentially modifications of the concept developed by DaVinci. Some of these include the following [1]:

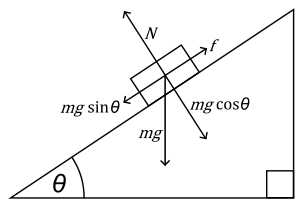

- Inclined plane test: In this test, one body is placed on a plane that is systematically inclined until the body starts to move.

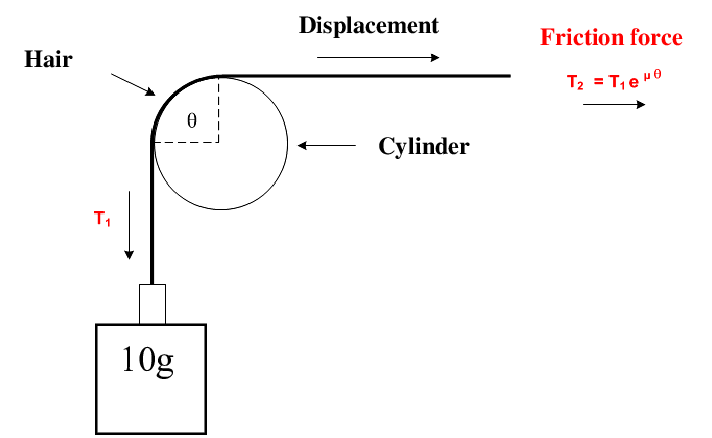

- Capstan test: This principle is used in capstans to hold lines under tension. The test involves a belt, a cable, and a rope or a web sliding over a roll or cylinder. The test simulates the slip of a plastic film on a roll during manufacturing.

Typical values of the coefficient of friction

The coefficient of friction is strictly related to the two surfaces in contact and depends on many variables including the bulk material properties, the surface roughness, atmospheric dust, presence of oxide or other films on the surface, temperature, humidity and degree of contamination, amongst others [4].

The table below provides typical values for coefficients of static and dynamic (kinetic) friction for various materials under different conditions.

Table 1. The coefficients of static and dynamic friction of different materials under dry or greasy conditions [4].

|

Material |

Coefficient of Static Friction |

Coefficient of Dynamic Friction |

||

|

Dry |

Greasy |

Dry |

Greasy |

|

|

Hard steel on hard steel |

0.78 (1) |

0.11 (1) 0.23 (2) 0.15 (3) 0.11 (4) 0.0075 (5) 0.0052 (6) |

0.42 |

0.029 (6) 0.081 (3) 0.080 (7) 0.058 (8) 0.084 (4) 0.108 (13) 0.12 (1) |

|

0.85 |

-- |

0.21 |

-- |

|

|

Hard steel on graphite |

0.21 |

0.09 (1) |

-- |

-- |

|

Bronze on cast iron |

-- |

-- |

0.22 |

0.077 (10) |

|

Mild steel on cast iron |

-- |

0.183 (3) |

0.23 |

0.1333 (11) |

|

Nickel on mild steel |

-- |

-- |

0.64 |

0.178 (13) |

|

Nickel on nickel |

1.10 |

0.28 (15) |

0.53 |

0.12 (14) |

|

Magnesium on mild steel |

-- |

-- |

0.42 |

-- |

|

Magnesium on magnesium |

0.60 |

0.08 (15) |

-- |

-- |

|

Copper on mild steel |

058 |

-- |

0.36 |

0.18 (1) |

|

Aluminium on aluminium |

1.05 |

0.30 (15) |

1.4 |

-- |

|

Glass on glass |

0.94 |

0.35 (15) |

0.4 |

0.09 (1) |

|

Copper on glass |

0.68 |

-- |

0.53 |

-- |

|

Cast iron on cast iron |

-- |

-- |

0.22 |

0.077 (10) |

|

Teflon on Teflon |

004 |

-- |

0.04 (11) |

-- |

|

Laminated plastic on steel |

-- |

-- |

0.35 |

0.05 (12) |

|

Tungsten carbide on tungsten carbide |

0.20 |

0.12 (1) |

-- |

-- |

|

Tungsten carbide on steel |

0.50 |

0.08 (1) |

-- |

-- |

|

Oak on oak (parallel to grain) |

0.62 |

-- |

0.48 |

0.164 (16) |

| Lubricant References |

(1) Oleic acid |

(5) Palmitic acid (6) Stearic acid (7) Grease zinc oxide base (8) Graphite |

(9) Triolein (10) Olive oil (11) Medium mineral oil (12) Water |

(13) Turbine oil (medium mineral) (14) Octyl alcohol (15) 1% lauric acid in paraffin oil (16) Dry soap |

Sources

[1] ASM International Handbook Committee (1992), ASM Handbook, Volume 18: Friction, Lubrication, and Wear Technology.

[2] Bird, J. O. and Chivers, P. J. (1993), “Friction,” in Newnes Engineering and Physical Science Pocket Book, J O Bird, P J Chivers, Ed. Newnes, pp. 235–237.

[3] Persson, B.N.J. (1998), “Sliding Friction, Physical Principles and Applications”, Springer, Hamburg, Germany.

[4] Fuller, D., “Coefficients of friction”, Columbia University, [Online].