Choosing the Right Welding Process: GMAW vs TIG vs SMAW vs FCAW

AMPCO METAL

Welding has long been a process that requires skill and a proper understanding of the technique being used. Today, not only are welding processes indispensable and versatile, but they also vary in terms of type, requirements, and compatibility with the base materials. Welding of metals, like copper alloys, can give you plenty of choices to select from, whether it is welding positions, filler metals, or welding processes. Here, we will explore four common welding processes and what makes each of them stand out in order to help you make the right decision in process and material selection.

The four main types of welding processes are:

- Gas metal arc welding (GMAW): most commonly as metal inert gas (MIG) and metal active gas (MAG) welding

- Gas tungsten arc welding (GTAW): also known as tungsten inert gas (TIG) welding

- Shielded metal arc welding (SMAW): also known as manual metal arc welding (MMAW) or flux shielded arc welding

- Flux-cored arc welding (FCAW): an alternative to SMAW

When selecting a welding technique, there are multiple considerations and factors to take into account. Choosing the wrong welding process may result in undesirable welding defects, which could prove problematic to the quality of your end product.

The key factors to consider before selecting the welding process are:

- Type of base material to be welded

- Position of the weld

- Speed of travel, i.e., the rate at which the arc moves along the workpiece

- Material thickness and depth of penetration

- Time requirements

- Type of welding power source and amount of available electrical current

- Filler material

What type of welding process should you select?

There is a variety of welding processes used in the industry, including arc welding, resistance welding, and gas welding, to name a few. Here, our focus will be on arc welding.

Arc welding, in general, is a cost-effective technique that has been in use for over two centuries. It is based on the application of an electric arc between the electrode and the base metal generated by a welding power supply. This arc heats up the metal until it melts, which upon cooling, solidifies into a binding weld between the workpieces.

In the following sections, we will explain each of the four common arc welding techniques, explore the compatible materials, and compare the advantages of each process.

What is GMAW?

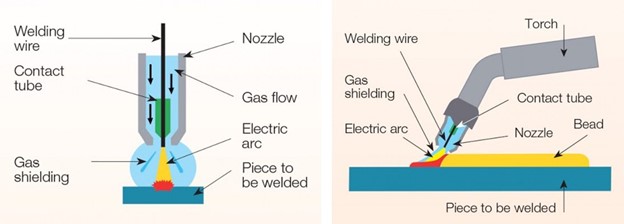

Gas metal arc welding (GMAW) is arguably the most commonly used welding process. It is quite flexible and is mainly found in the form of metal inert gas (MIG) welding or metal active gas (MAG) welding.

MIG welding uses a noble gas as the shielding gas to protect the weld pool from any external influences or contamination. Basically, the gas creates a layer impermeable by oxygen, which is the main factor in the oxidation and contamination of the molten metal. Usually, argon is used thanks to its ecoefficiency. Helium is another useful yet relatively expensive option. Typically, such gases are used for MIG welding of non-ferrous metals like copper, aluminium, and aluminium bronze.

MAG welding, on the other hand, uses reactive gases. Similarly, it shields the welding area from external effects, but the gas actually reacts with the piece being welded. The gas composition has a significant influence on the arc stability, the amount of weld spatter, and the metal transfer, not to mention the penetration and weld properties. Generally, carbon dioxide is used as a shielding gas, and in many cases, it is mixed with other gases to ensure proper protection. Such gases are used for welding alloyed or unalloyed steel.

GMAW characteristically employs a consumable solid wire electrode that is passed through the welding gun. Under an electric current, this wire (or filler metal) ignites the welding arc upon contact with the workpiece and begins to melt and fuse with the base metal.

GMAW can supply high deposition rates, high efficiency, and excellent quality. It also requires less energy otherwise needed for workpiece preheating and less human labour.

It is compatible with and commonly used for depositing aluminium bronze and copper alloys such as AMPCO-TRODE® and COPR-TRODE® alloys from AMPCO METAL. AMPCO-TRODE® is a series of aluminium bronze wire that can yield a strong and ductile deposit to weld different kinds of metals.

- AMPCO-TRODE® 10 is used to weld ferrous, non-ferrous, and dissimilar metals, such as cast iron, high- and low-carbon steel, copper, bronze, and copper-nickel alloys.

- AMPCO-TRODE®46 is used to weld cast and wrought nickel-aluminium bronze. It is recommended for weld repairing NiBral boat propellers.

- AMPCO-TRODE® 150 is used for welding wrought copper bronze alloys like AMPCO® 18.

- AMPCO-TRODE® 940 is used as an effective alternative to beryllium copper, and it specifically helps repair complex AMPCOLOY® 940 moulds used in the plastic industry.

- COPR-TRODE® is a phosphor bronze alloy used to fabricate deoxidised copper and repair weld copper castings. It is also used to weld galvanised steel.

- Other wire materials include AMPCO-CORE® 200, 250, and 300.

Check Table 1 below for GMAW’s advantages as compared to the other welding processes.

A graphic of the GMAW process (AMPCO METAL)

What is GTAW (TIG welding)?

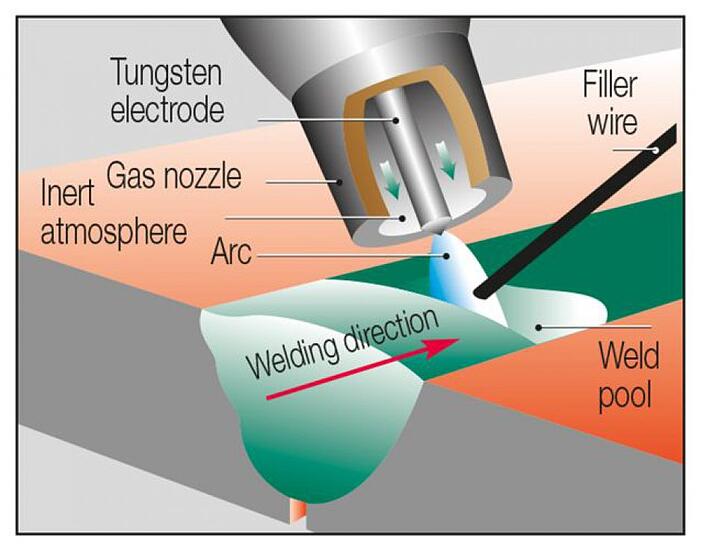

GTAW, or TIG welding, is also an arc welding process that utilises a shielding gas. Just like in MIG welding, inert gases like argon and helium are used for arc and weld protection from oxygen and other contaminants. However, TIG welding employs a non-consumable electrode, which is made of pure or alloyed tungsten. A non-consumable electrode is a wire or rod that does not melt under the existing heat due to its high melting point. This electrode allows for a freely burning electric arc with the workpiece.

GTAW is generally used to weld all kinds of metal. Particularly, when welding aluminium bronze material, it is utilised to repair castings and forming dies or to produce copper alloy piping systems.

It is, usually, the process of choice when extremely high quality and precision control is required. Thus, the weld quality under GTAW correlates with the skill of the operator.

TIG welding is compatible with similar filler metals as GMAW, including AMPCO-TRODE® 10, 46, 150, and 940.

Check Table 1 below for GTAW’s advantages as compared to the other welding processes.

A graphic of the GTAW process (AMPCO METAL)

What is SMAW?

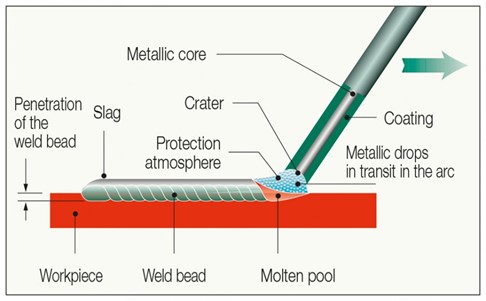

SMAW, also known as flux shielded arc welding, is a manual arc welding process that employs a consumable electrode. Its distinguishing attribute is that the electric arc takes place between a manually guided stick electrode and the metal work. This has given it the practical name “stick welding”.

This process does not require the supply of a shielding gas, as the consumable electrode typically holds a flux material that assumes the shielding task. When an electric current is supplied, this flux material disintegrates to form protective inert gases and a layer of slag to shield the molten metal from oxidation. The slag can simply be removed upon solidification. As a result, SMAW does not require relatively heavy equipment, such as a separate gas tank that otherwise would deliver a shielding gas.

SMAW is portable, and its equipment is simple and easily accessible. That is why it is a process of choice for applications of maintenance and repairing, mostly in industrial manufacturing and construction of steel structures. However, the operator’s skill and the electrode’s positioning, movement, and inclination can all significantly affect the weld quality. Besides, precleaning of the work surface and filler metal selection are vital for achieving high-quality welds.

SMAW is well-suited to deposit similar filler metals like AMPCO-TRODE® 10, 46, and 150, and AMPCO-CORE® 200, 250, and 300.

Check Table 1 below for SMAW’s advantages as compared to the other welding processes.

A graphic of the SMAW process (AMPCO METAL)

What is FCAW?

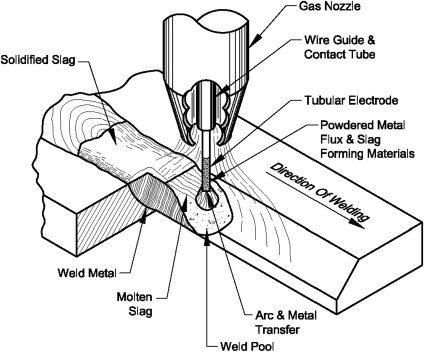

FCAW is a more recent arc welding process particularly developed as an alternative to SMAW. It was introduced in 1950 as a technique that can be either automatic or semi-automatic. It employs a consumable tubular electrode that is fed continuously in a similar way to MAG welding.

However, FCAW’s distinctiveness can be found in its shielding capabilities. FCAW comes in two different possibilities, one that does not use a supplementary shielding gas and one that does.

In the first option, the process makes use of the electrode’s own flux material that, upon disintegration under heat, produces the shielding gases and slag to protect the melt. Such a process is commonly referred to as “self-shielded process”.

On the other hand, the second option takes advantage of a shielding gas and is, thus, named “gas-shielded process”. What is significant about this process is that flux material on the electrode still performs its shielding function by forming a slag, which is what earned it the name “dual shield welding”. FCAW mainly uses CO2 as the shielding gas, which is often used in a gas mixture with argon.

FCAW is applied similarly to SMAW, but it can also be used in outer settings, which is why it is commonly a chosen welding process in the marine industry.

FCAW’s most compatible filler metals include AMPCO-CORE® 200, 250, 250s, and 300.

Check Table 1 below for FCAW’s advantages as compared to the other welding processes.

A graphic of the FCAW process (AMPCO METAL)

Table 1. Advantages of each arc welding process.

|

GMAW |

GTAW |

SMAW |

FCAW |

|

GMAW can be fully automatic, resulting in higher productivity. GMAW can be used for all metals and alloys. GMAW can be used in all weld positions. GMAW produces lower levels of fumes as compared to FCAW or SMAW. |

GTAW is versatile as it can be used to weld almost all metals. GTAW allows for a high degree of control, and when done correctly, yields excellent results. GTAW does not create any spatter that must later be cleaned up. |

SMAW has relatively simple equipment. SMAW is the most portable of all welding processes SMAW does not need separate gas shielding SMAW can be used in a wide range of environments, including outdoors, in fabrication shops, on pipelines and refineries, on ships and bridges, among others. SMAW is not sensitive to wind and draft. |

FCAW yields high quality. FCAW produces consistent welds with fewer defects. FCAW has a high deposition rate. FCAW can be used in all positions with the right filler metal. FCAW is suitable for outdoor welding or shop welding. |

Where to find suitable welding materials?

Choosing the most suitable material is as important as selecting the right welding process. That is why material suppliers, like AMPCO METAL, make sure that engineers and welders have a good understanding of the different material options so they can make an informed decision.

AMPCO METAL’s presence on Matmatch has given millions of users the opportunity to explore, compare, and select the right materials for their projects. This respectable producer has been providing their customers with metals in various forms for more than 100 years and continues to do so at the highest level.

Visit the AMPCO METAL supplier page for more information about their materials and to get in direct contact with them.

Artikel von <a href=/suppliers/ampc-ampco-metal> AMPCO METAL </a>AMPCO METAL

AMPCO METAL, headquartered in Switzerland, is a leading international manufacturer and integrated distributor of specialty copper alloys and engineered products.

The company was founded in 1914 in the USA, as an innovator in the introduction and application of aluminium bronze alloys.

It has also introduced to the market several new metallurgical and process techniques that have made AMPCO METAL the recognized quality leader in specialty bronzes and copper alloys.

Over the years, AMPCO METAL has served customers throughout the world in a variety of applications seeking wear, corrosion-resistant and high conductive properties.

Major industries served include: chemical and petroleum, machine tool, primary metal producers, transportation and a wide range of industrial and commercial machinery.

To obtain unique and consistent alloy characteristics, AMPCO METAL utilizes some of the most advanced equipments in the industry, a highly skilled engineering staff and sophisticated quality control procedures.

This allows AMPCO METAL to offer superior lot-to-lot consistency for predictable results.Conscious of the environment, AMPCO METAL utilizes advanced technology throughout its plants and service centers to rigidly maintain clean air and water programs.

AMPCO METAL manufactures a wide range of alloys in a variety of grades and conditions and distributes them through its worldwide network of service centers. This enables AMPCO METAL to work closely with its customers to produce specialty alloys with the properties and characteristics they need.

A century of engineered excellence

Since 1914, AMPCO METAL has worked with industry partners across the Aerospace, Automotive, Steel & Titanium industries, as well as Marine, Oil, Gas & Chemical, along with and a host of others., across a range of applications, including friction & wear, corrosion resistance and heat & electrical conductivity. This unparalleled experience, combined with our technical expertise and engineered alloy excellence mean we’re able to be a global partner in creating metal solutions for our customers.

Superior Casting

Introducing MICROCAST®, our patented high-performance aluminium bronze and specialty copper alloy production technology that delivers the most uniform grain size with the most outstanding wear resistance.

AMPCO®Aluminium Bronze

- A highly polishable, high-strength and better alternative to brass with better grain.

- Higher mechanical properties without lead and cleaner trace elements.

- High wear characteristics and corrosion resistance.

- Best movement material for sliding, motion and typical wear parts with friction problems.

- Recommended for how to solve cavitation problems, galling, tooth flank damage, avoiding nickel contamination and surface problems on stainless steel.

Aluminium bronzes are part of a copper alloys family containing aluminum as their principal alloying element. The properties of these alloys are governed by the properties of copper and aluminium when melted and casted together in rigorous and well-controlled processes.

Aluminium is soluble in copper up to about 8 wt%. This solution is characterized by a homogeneous single alpha phase which displays high ductility and excellent corrosion resistance by forming a protective skin of aluminum oxide on the surface. When increasing the aluminium content, a second phase forms in the microstructure known as the beta phase. These alloys are harder than a single alpha phase, with higher strength and higher mechanical properties.

Other alloying elements can be used like nickel to further improve the resistance to corrosion and mechanical properties. These alloys are used in highly-loaded construction parts that can be exposed to aggressive corrosion environments.

AMPCO METAL was a pioneer in developing aluminium bronze alloys and continues to engineer premium products for critical applications with its well-known AMPCO® product line to this day. Our high-quality, high property and uniquely hard metal range is trusted the world over for its broad use. AMPCO® Aluminium Bronze even extends to food-approved applications through alloys such as AMPCO® 8, AMPCO® 18 and AMPCO® M4.

AMPCOLOY®High Copper Alloy

- A polished hard version copper alloy without coating or lead and clean trace elements

- Best material for injection moulding and welding, with the highest thermal conductivity for mould problems.

- An alternative to Wolfram cathodes for cathode welding material.

- Increases productivity of plastic injection while decreasing their cycle times.

- Also used when food approval is required.

AMPCOLOY® High Copper alloys are engineered with exceptional conductivity, high strength and unique wear characteristics, delivering higher lifetime, quality and performance, with cleaner trace elements. Copper has a face-centered cubic lattice, allowing it to have good cold working properties in addition to high electrical and thermal conductivity. With the addition of carefully selected alloying elements in well-defined proportion, high copper alloys develop the necessary strength and hardness properties with little decrease in electrical conductivity. These material are used in critical applications where both conductivity and mechanical properties are required.

With over a century of expertise, AMPCO METAL and its AMPCOLOY® product line are synonymous with premium quality for critical applications.

AMS Alloys

- Technically specific AMS bronze is used for parts and landing gear.

- Sometimes referred to as aerospace bronze.

AMS alloys are the results of carefully selected alloying elements, well-documented manufacturing processes and specific heat treatment parameters, achieving quality and performances that critical applications like the aerospace industry require.

Standard Alloys

- Offers high flexibility in value, size, and shape.

Standard Alloys continue the AMPCO tradition of excellence in engineered alloys, offering a premium product that can offer performance for demanding applications.

Other Alloys

- Often considered as an alternative to aluminum bronze.

Our high-strength, durable AMPCO® Alloy range and bearing material, recognized for its unparalleled ability to perform under temperature. It’s created through a patented manufacturing process that gives it greater corrosion-resistant properties for a number of specific applications.