What is Dielectric Strength?

Dielectric strength is an intrinsic material property that represents the maximum electric field a pure material is able to sustain ideally before its insulating properties begin to fail. It can also be described as the highest voltage needed to induce a dielectric breakdown [1].

A dielectric material, or dielectric in short, is in fact an electrical insulator, which may be polarised in the presence of an electric field. This means when subjected to an external electric field, the material does not allow any current flow as there are no free electrons to move through the material (bearing in mind there are no “perfect” insulators). Rather an electric polarisation takes place, where static electric charges come into play, having a constant amount of charge and a stationary position relative to one another. What defines this material’s ability to create a polarity is its dielectric constant.

Dielectric strength should not be confused with the dielectric constant, although they are interrelated. While the dielectric strength characterises the material’s insulating quality, the dielectric constant is a dimensionless mathematical ratio of the material permittivity to the permittivity of vacuum, which gives it the alternative name “relative permittivity”.

Dielectric strength is expressed in Volts per unit thickness (V/m) and is independent of the material configuration or the electric field-generating electrodes. It is an essential property of an insulator, whose quality changes proportionally with the change in dielectric strength.

Here, you will learn about:

- What a dielectric breakdown is

- How dielectric strength is measured

- What the most common materials that characterise with their dielectric strength are

- What applications are based on the materials’ dielectric strengths

What is a dielectric breakdown?

Consider exposing a particular dielectric material, such as glass or porcelain, to a certain voltage. Constantly increasing this voltage will cause the material to slowly approach its maximum ability to hold back any electron flow from flowing (i.e. its dielectric strength), after which a sudden, local, and catastrophic event takes place [2]. We call that the dielectric breakdown.

What happens at breakdown is that the external electric field frees electrons that were bound to their relative atoms in a matter of nanoseconds, creating an electrically conductive path, or a puncture, through which an electrostatic discharge (ESD) occurs. In other words, current abruptly increases from the saturation value, resulting in an avalanche of electrons. This causes the material to burn in the breakdown area, which leads to severe degradation and even full loss of its insulating capacity. Such breakdowns are by nature irreproducible, stochastic, and may differ based on the material’s physical state, purity, and environment [2].

In addition to this intrinsic breakdown, it is important to point out that breakdown is possible to happen in more specific ways, such as [3]:

- Thermal breakdown, which is described in terms of the dielectric material’s thermal properties and is related to Joule heating.

- Discharge breakdown, which is important in ceramics as it is initiated at the level of porosities, a common inhomogeneity in ceramics.

How is dielectric strength measured?

Well-defined testing procedures have been devised to measure the dielectric strength of insulating materials. Yet, it is critical to keep in mind that these standard tests do not measure an intrinsic value of dielectric strength as premature discharges may take place in the medium around the tested specimens [2].

There are four common tests that involve the application of voltage in order to measure the dielectric properties of a material [4].

1. Test for specified minimum requirement

This test does not really measure the dielectric strength per se; instead, it measures the dielectric withstand of the material. That’s why it is also called the dielectric withstand test [5]. Dielectric withstand means the insulating material’s ability to withstand a high voltage for a particular period of time before it fails.

In this test, voltage is applied across the material and increased at a constant rate (usually 5% of the specified voltage) till the value indicated in the material specification is reached, at which it is kept for a specified time.

2. Test to breakdown, short-time test

In this test, applied voltage is increased from zero at a uniform rate (0.5-1.0 kV/s) until breakdown. This voltage rise rate is selected based on the overall time of the test and the material’s voltage-time characteristic.

3. Test to breakdown, step-by-step test

Here, the voltage is increased from a starting point of 50% of the breakdown voltage specified in the short-time test. The same rate of rise is applied, but the value is held after every equal increment for a defined period of time and then increased as fast as possible to the next value.

4. Test to breakdown, slow-rate-of-test

The voltage in this test is also applied initially at half the breakdown voltage and increased at a uniform rate until the breakdown point. This rate is selected to give an equal voltage-time exposure of the test specimen.

The dielectric strength is then calculated by simply dividing the breakdown voltage by the sample material’s thickness, which should be large enough to prevent flashover from happening before breakdown. Keep in mind that the relationship between the dielectric strength and the thickness is not necessarily linear.

What applications and materials characterise with dielectric strength?

Common materials with their relative dielectric strengths can be viewed in the table below. Notice the difference in value for similar materials when the film thickness is changed.

|

Material |

Dielectric Strength [kV/mm] |

|

190 |

|

|

160 |

|

|

128 |

|

|

120 |

|

|

120 |

|

|

118 - 236 |

|

|

79 |

|

|

70 |

|

|

70 |

|

|

25 |

|

|

25 |

|

|

23 |

|

|

17 |

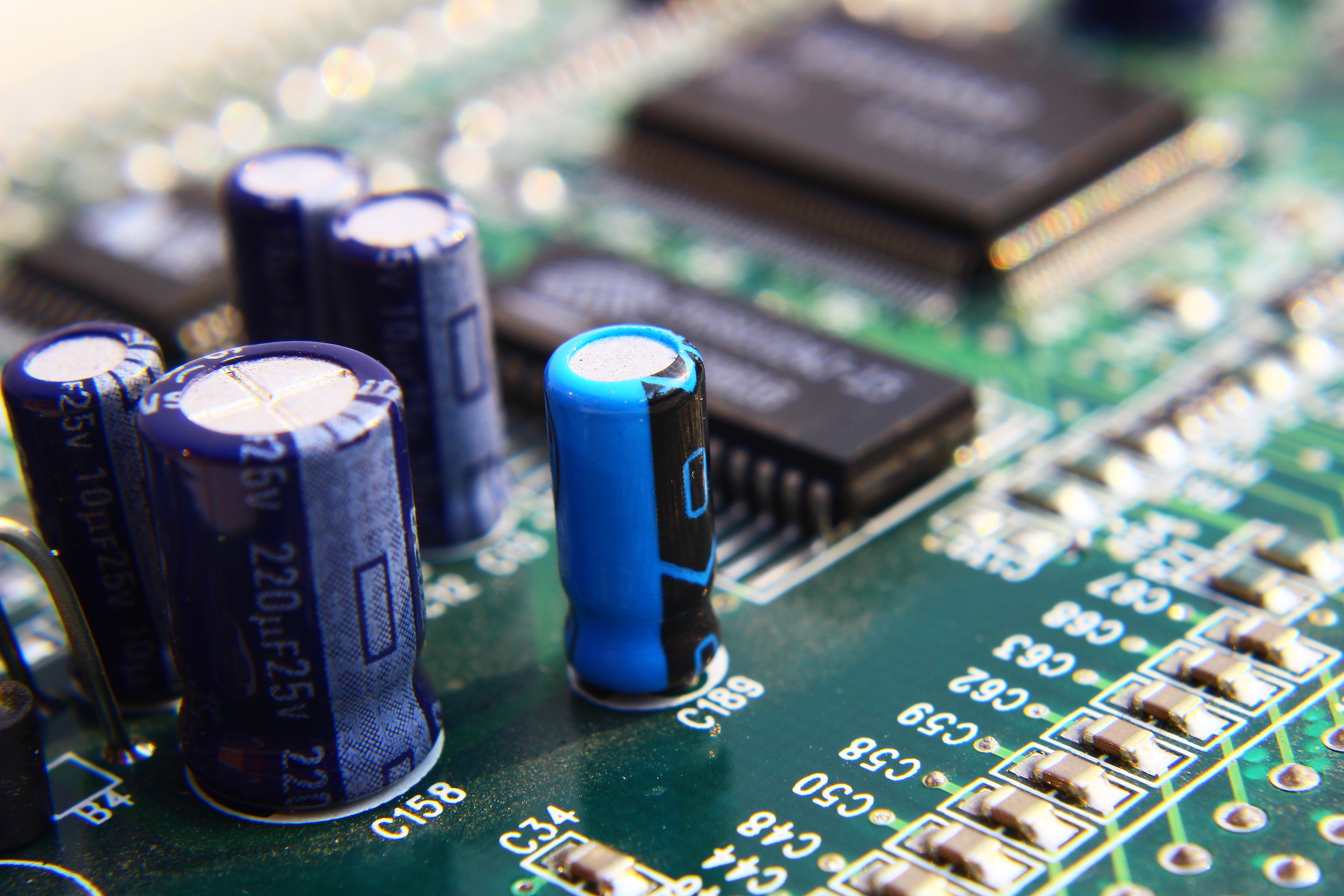

Dielectric strength is an important factor in material selection when it comes to electrical insulation. Most commonly used in the electrical and electronic industry, dielectric strength plays a major role in applications such as coating, potting, and encapsulation of electronic devices. It is also used in the material selection and design of capacitors, where dielectric materials provide high electrical storage capacity when placed between the capacitor’s conducting plates. Dielectrics in capacitors can be vacuum, gaseous (such as air), liquid (such as mineral oil), solid (such as glass, titanium oxide, or sodium) or a combination of liquid and solid (such as oil impregnated paper or mica). Dielectrics are also used in power transformers, spark generators, cables, and transducers.

Dielectric strength is significantly considered in the medical industry, as well, as insulation is needed for certain devices and equipment in order to shield patients and medical staff from electric currents, especially when the device is connected to a power supply.

Conclusion

Keep in mind that the naming of an insulating material as dielectric rather than insulator depends on its main function. If its main function is to provide electrical insulation, it is an insulator (also called passive dielectric). If its main function is to store electrical charge, on the other hand, it is a dielectric (also called active dielectric).

Dielectric materials, in general, are non-metallics with significantly high resistivity. Their dielectric strength defines their breakdown voltage applied through the material thickness.

Check out the list of dielectric materials here on Matmatch with their corresponding dielectric strengths and find out who provides them.

Sources

[1] M. Kutz, “Dielectric Strength”, Handbook of Materials Selection, NY: John Wiley & Sons, 2002.

[2] A.R. Blythe, T. Blythe, and D. Bloor, “Dielectric breakdown”, Electrical Properties of Polymers, UK: Cambridge University Press, 2005.

[3] A.J. Moulson, J.M. Herbert, “Dielectric Strength”, Electroceramics: Materials, Properties, Applications, UK: Chapman and Hall, 1990.

[4] The Institute for Interconnecting and Packaging Electronic Circuits, “Dielectric breakdown voltage and dielectric strength”, IPC-TM-650 Test Methods Manual [Online]. Available at: https://www.ipc.org/TM/2.5.6.3.pdf [Accessed on: 26.11.2019].

[5] “Dielectric Strength Testing”, element.com [Online]. Available at: https://www.element.com/materials-testing-services/dielectric-strength-testing [Accessed on: 26.11.2019]