Blow Moulding: History, Process, and Types

The idea of creating diverse useful shapes by using air to blow a heated material was first employed by the Syrian glass workers about 3,000 years. The process used by Syrians consisted in placing a long tube into a receptacle, located in a blast furnace with liquid gas, removing the blob of white-hot liquid glass, spinning it, and finally blowing into a mouthpiece on the other end of the tube. This process later was refined in Europe during the Middle Ages due to the demand for bottles to contain and ship products such as wine. Egyptians also have records of blow moulding in the royal thumbs and further developments between 1700-1600 BC [1].

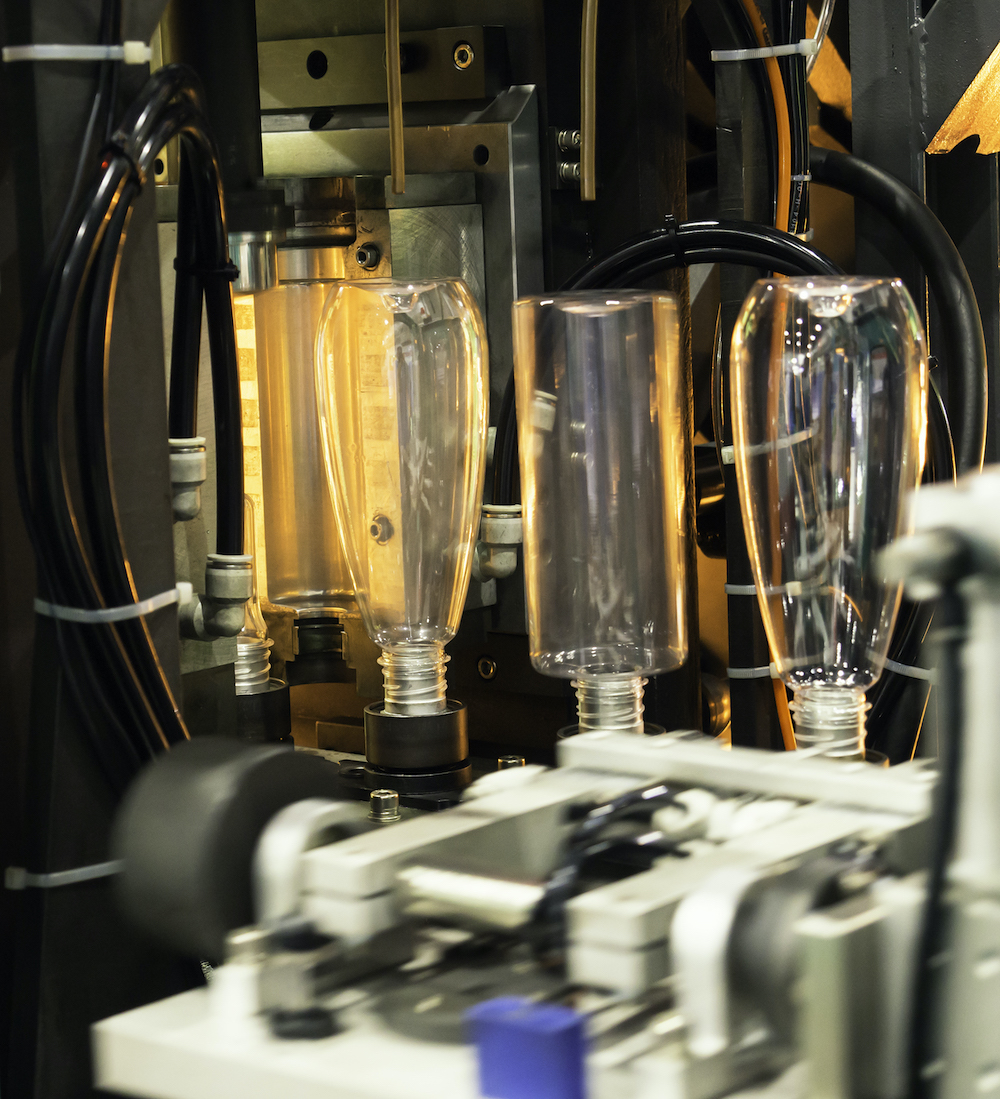

The process of blow moulding is widely used to produce hollow containers that range from commodity products, such as soda or water bottles, to highly engineered products such as gas tanks or electrical enclosures [1].

The global market for blow moulding products has an important size, particularly for the blow moulded plastics, for which about USD 75 billion were estimated in 2018 with a projection of 4.5% between 2019 and 2025. The growing demands include the construction, automotive, and packaging industries with lead markets in Brazil, Russia, India, China, and South Africa and growth additions in the recent years in the Middle East and the Asia Pacific [3].

In this article you will learn about:

- The history of blow moulding

- The blow moulding process

- Types of blow moulding

- Future trends of blow moulding

The history of blow moulding

The official application of blow moulding began with the use of celluloid and celluloid nitrate that were used to develop a limited number of products as the celluloid is highly flammable. The process was commercialised with the first automatic blow moulding machine by the Plax Corporation in the 1930s. By 1939, this corporation had a machine capable of producing 25,000 bottles per day, and in 1945, introduced the use of the recently developed low-density polyethylene (LDPE) to squeeze bottles.

In 1953, the market for blow moulding products exploded with the appearance of high-density polyethylene (HDPE). The introduction of polyethylene terephthalate (PET) in the 1970s also allowed the development of more efficient processes. The production of other diverse resins with time allowed a wide range of other material properties to become available, the appearance of larger and more robust equipment, that lead to the production of a large range of industrial and technical applications [2].

The blow moulding process

The process of blow moulding consists of forming a hollow object by literally blowing a thermoplastic hollow cylinder called parison or preform, in the shape of a mould cavity. The parison is dropped between two female open-mould halves, which are shaped to the desired product. Once the parison has enough length, it is heated and blown with pressurised gas, generally air, against the mould. The product is cooled and crystallised until it is removed from the blow mould to avoid deformation [1].

Typical materials used for processing by blow moulding are shown in the table below.

Table 1. Materials processed by blow moulding [6]

|

Material |

Acronym |

|

Polyethylene (Low Density) |

|

|

Polypropylene |

|

|

Polyethylene - Terephthalate |

|

|

Polyvinyl chloride |

|

|

Polyethylene (High Density) |

Types of blow moulding

The most common processes of blow moulding are extrusion blow moulding, injection blow moulding, and stretch moulding.

Figure 1. Breakdown of blow moulding methods

Extrusion blow moulding

Extrusion blow moulding is the process where:

- The thermoplastic material is melted and extruded (expelled) into the hollow tube (parison),

- The mould is closed,

- Compressed air is blown into the parison filling the mould,

- Finally, after cooling and crystallization, the product is removed.

The extrusion process is further divided into continuous and intermittent processes. In the continuous process, the parison is extruded continuously and the mould is opened and closed to complete the process. On the other hand, in the intermittent process, the material is collected by the extruder and then pushed to the die.

Extrusion is the most common method in blow moulding and is used in manufacturing products such as milk bottles, shampoo bottles, automotive ducting, watering cans, and other industrial parts. The main advantages of this method are the low cost and fast production rates, as well as the ability to produce complex geometries. Some of the limitations include the mere production of hollow parts and the material’s low strength. When used for producing wide neck bottles, spin trimming is required [4][6].

Injection blow moulding

Injection blow moulding is the process where the material is melted and injected (forced) into a precisely dimensioned die until it cools and solidifies to the desired product shape. The process consists of three steps: injection, blowing, and ejection.

Injection blow moulding is mainly used to produce bottles, jars, and containers in large quantities. This method is less common due to the limitations on the production rate and is preferably used for small products such as those for medical applications. Its main advantage is the ability to produce accurately complex-moulded necks. However, it suffers from the restriction to small bottles production only and low strength in the barrier [5].

Stretch moulding

In stretch moulding, the parison is formed in a similar way as the injection blow moulding, but with the difference that once transferred to the blow mould, it is heated and stretched downward by the core before inflation. The stretching method allows for the use of increased strength in the material.

Stretch moulding is highly advantageous for low volumes and for allowing the mould wall to be shaped in rectangular and non-round shapes. Yet, the method has restrictions on bottle designs. It is used to produce parts subjected to internal pressures or with high durability demands, such as soda bottles [6].

Future trends

The future of blow moulding is the innovation of machinery. Diverse equipment that include energy-efficient features has been developed in the recent years (i.e., EBLOW 37 for manufacturing of canister for packing industry). The challenge of this technology is in offering a technological, economical and attractive solution for product manufacturing that also include considerations regarding environmental concerns on product disposal [3].

Sources

[1] Belcher, S.L., Blow Moulding, Applied Plastics Engineering Handbook, Second ed., 2017

[2] Lee, N. Practical Guide to Blow Moulding, Rapra Technology Limited, Shawbury, Shrewsbury, United Kingdom, 2006

[3] Grand View Research, “Blow Molded Plastics Market Size, Share and Trends Analysis Report, By Technology (Extrusion, Injection, Stretch, Compound), By Product (PP, ABS, PE, Polystyrene, PVC, PET), By Application, And Segment Forecasts, 2019 – 2025”, https://www.grandviewresearch.com/industry-analysis/blow-molded-plastics-market (accessed February 16, 2020)

[4] Wagner, J.R., Extrusion Blow Moulding, Applied Plastics Engineering Handbook, Second ed., 2017

[5] Belcher, S.L., Practical Guide to Injection Blow Moulding, CRC Press, 2007

[6] British Plastics Federation, “Injection Blow Moulding” https://www.bpf.co.uk/plastipedia/processes/injection_blow_moulding.aspx (accessed February 16, 2020)