1.4980 (A286 Steel): An Austenitic Stainless Steel that Epitomises Heat Resistance

Remystahl GmbH & Co. KG

Thermal resistance is a property that is at the centre of material properties required by high-temperature application areas. From industrial applications such as power plant engineering and power generation to automotive and aerospace applications, many materials have to be resistant to heat in order for the system to operate properly without failure. Heat-resistant steels, in particular, are materials used to tolerate temperatures between 500 and 1150 °C. They are, generally, austenitic steel alloys that are rich in nickel and chromium with very low levels of carbon. For instance, 1.4980, also known as A286 steel, is an austenitic precipitation-hardened stainless steel, and its excellent heat and creep resistance have enabled its use at temperatures reaching up to 700 °C. In this article, we will discuss how heat-resistant steels, like 1.4980, are used, and what their most suitable application areas are.

(Remystahl)

Thermal resistance, by definition, is the resistance of a material against a certain flow of heat. It is expressed as the ratio of the temperature difference between two defined surfaces to the heat flow rate per unit area. Heat-resistant materials are generally used in high-temperature applications either to maintain a process from failing during operation at elevated temperatures or to protect elements and components from the heat generated during the operation processes.

Particularly, heat-resistant steels are steels that are required to be resistant not only to heat but also to corrosion at high temperatures, while maintaining high levels of creep strength, mechanical strength, and stability in their microstructure. They also have good scaling resistance due to a protective oxide layer created on their surface, and they are durable against stresses that arise from continuously fluctuating temperatures. Austenitic stainless-steel materials, the most commonly used variant of stainless steel, owe their wide-range applicability to their ability to operate at high temperatures with excellent formability, corrosion- and wear-resistance.

What is A286 stainless steel?

A286 stainless steel, or 1.4980, is an austenitic precipitation-hardenable stainless steel that is generally configured for long-term and high-temperature use with a service temperature reaching up to 700 °C. It is considered as an iron-based superalloy due to its high strength and resistance to corrosion at high temperatures.

(Remystahl)

Chemical composition of A286 stainless steel

1.4980 is a chromium-nickel stainless steel alloy, a composition that defines its high mechanical and fatigue strength. It can be age-hardened via heat treatments to uniformly improve its hardness and yield strength, resulting in easy replication in manufacturing. Table 1 below shows the chemical composition of 1.4980, as supplied by Remystahl.

Table 1. Chemical composition of 1.4980 (A286 stainless steel)

|

Element |

Weight % |

|

Fe |

Balance |

|

Ni |

24 – 27 % |

|

Cr |

15 – 17 % |

|

Mn |

1.5 % (max.) |

|

Si |

0.3 – 0.6 % |

|

C |

0.04 – 0.1 % |

|

P |

0.04 % (max.) |

|

S |

0.015 % (max.) |

|

Ti |

0.0004 % (max.) |

Properties of A286 stainless steel

In addition to its high mechanical properties and high service temperature, 1.4980 has a high melting point and can be supplied in various dimensions and sizes. This renders it highly versatile in terms of its application areas. Table 2 below shows a list of 1.4980’s different properties.

Table 2. Mechanical, thermal, and physical properties of 1.4980.

|

|

1.4980 (A286 stainless steel) |

|

Mechanical Properties |

|

|

16 % |

|

|

248 – 341 |

|

|

900 – 1150 MPa |

|

|

600 MPa |

|

|

206.7 GPa |

|

|

0.28 |

|

|

Thermal Properties |

|

|

1.7 x 10-5 1/K |

|

|

Max. service temperature, long |

0 – 700 °C |

|

Melting point |

1370 – 1430 °C |

|

Physical Properties |

|

|

Density |

8 g/cm3 |

|

Dimensions (supplied by Remystahl) |

|

|

Round-bar length |

6.5 – 310 mm |

|

Hexagonal-bar length |

13 – 60 mm |

Alongside the properties above, 1.4980 has the following features that enable it to be a highly useful material in high-temperature applications:

- It has good machinability.

- It is highly resistant to corrosion, even at elevated temperatures.

- It has good oxidation resistance (up to 800 °C).

- It is non-magnetic even after undergoing severe cold deformation (down to -196 °C).

- Its mechanical strength is well sustained at temperatures reaching up to 700 °C.

- It has good ductility, allowing it to be cold-worked and formed under standard processing practices.

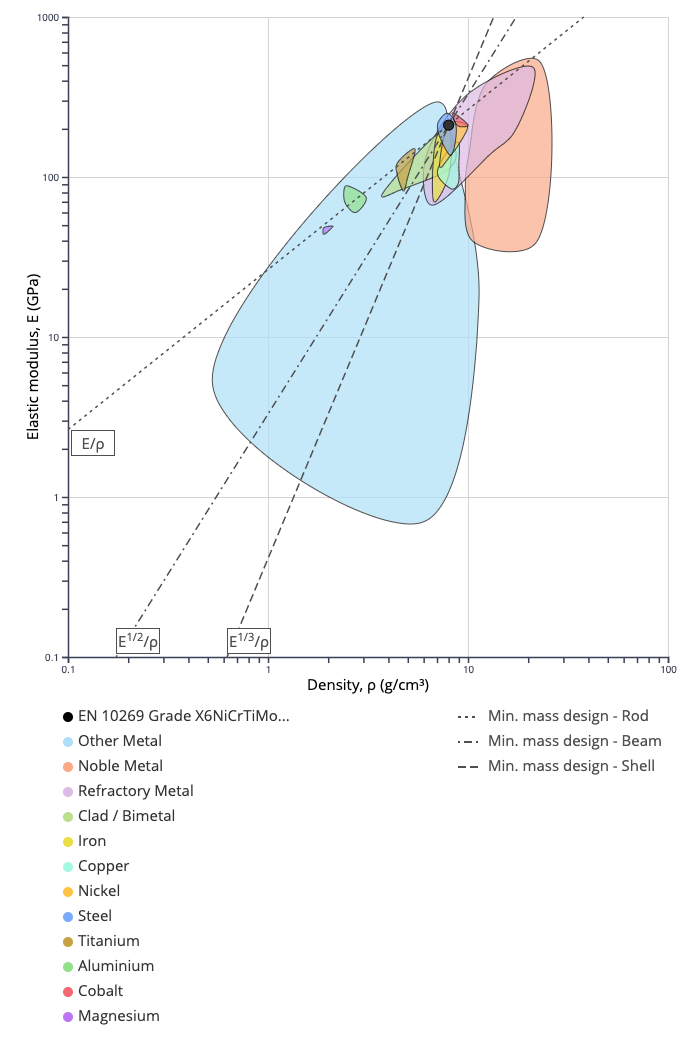

Figure 1 below shows a Matmatch Ashby chart for density and elastic modulus. The specified point is where 1.4980 sits as compared to other metals (shown under its equivalent standard EN 10269). For further data, click here to interact with the displayed chart and compare materials on different levels.

Figure 1. Ashby chart of density vs elastic modulus showing the difference between different metals and displaying the position of 1.4980.

Applications of A286 stainless steel

A286 steel (1.4980), similarly to other stainless-steel grades, is an all-around material that is used in application areas ranging from aerospace to mechanical systems, power stations and building elements. Since such applications require high strength, high corrosion resistance and high oxidation resistance, this particular superalloy is highly favourable for these uses.

Particularly, it is used in aerospace fasteners, such as screws, nuts, bolts, rivets, and pins. These are utilised in engines, turbines, and superchargers of space- and aircraft. It is also a material of choice for jet engine components, industrial gas turbines (such as runners, discs, shafts, extension rings, fittings, and housings), non-magnetic cryogenic systems, pumps and heat exchangers, in addition to superchargers in the automotive sector. Power generation components, furthermore, are application areas that require high resistance to corrosion, especially in severe conditions of high temperature and pressure. 1.4980 is a well-suited material for such components, especially due to its high service temperature over long periods of time.

Where to find high-resistant steels

Heat-resistant steels, just like 1.4980, are highly valuable materials, and it is important for engineers and product developers in their respective areas of study or work to find these materials easily during their material selection process.

Luckily, suppliers and material distributors, like Remystahl, have been providing materials in the steel industry for over 150 years. With over 60 different materials provided in various dimensions and shapes and a stock of about 5000 tons of steel, Remystahl is a trusted source that engineers can rely on when it comes to finding and buying high-quality steel materials. They have joined Matmatch to improve the material selection process for engineers worldwide by providing the necessary data and material supply.

Visit the Remystahl supplier page for more information on their materials listed on Matmatch and to get in direct contact with them.

Artículo de <a href=/suppliers/remy-remystahl-gmbh-co-kg> Remystahl GmbH & Co. KG </a>Remystahl GmbH & Co. KG

Remystahl GmbH & Co. KG is a private medium-sized company in the steel industry.

Our business is our passion. And that for over 150 years already. Remy started out as a steelwork. Today we deal in steel.

Over 150 years of experience. We know exactly what we are talking about when we talk about steel. And that is as it should be, because steel has long since stopped being a standard product these days. Its quality, processing and availability need to meet highly specific needs and requirements.

Good when you can rely on the comprehensive competence of a specialist. Because that is what REMYSTAHL is. We stand for this amongst our customers.

We.Know.Steel.